A method for controlling shelling of electrolytic aluminum

A control method and electrolytic aluminum technology, which is applied in the field of aluminum electrolysis, can solve problems such as poor feeding, lower quality of primary aluminum, and high energy consumption, and achieve the effects of improving the success rate of shelling, reducing labor intensity, and reducing inspection intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

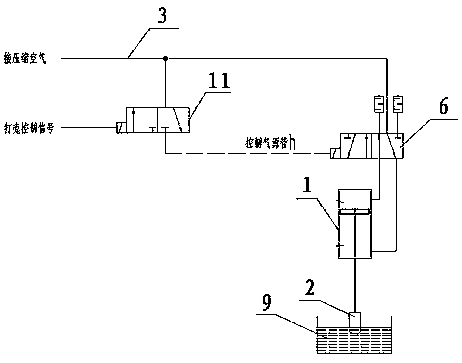

[0040] As shown in the figure, the electrolytic aluminum shelling control method of this patent uses a voltage sensor 7 on the piston rod of the shelling cylinder 1 to measure the voltage of the electrolyte 9 when the striking hammer 2 contacts the electrolyte 9 ; Pneumatic pressure sensor 8 is installed at the exhaust port of the rodless cavity of the shelling cylinder 1 to monitor the exhaust air pressure of the rodless cavity of the shelling cylinder 1; the voltage sensor 7 and the pneumatic pressure sensor 8 respectively feedback the electrolyte voltage signal and The exhaust air pressure feedback signal is transmitted to the intelligent control cabinet 5 for control; the intelligent control cabinet 5 controls the action of the shelling cylinder 1 according to the received electrolyte voltage feedback signal and the exhaust air pressure feedback signal, and the received electrolyte voltage feedback signal controls the shelling cylinder 1 is better than the exhaust air pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com