Method for manufacturing cold-rolled ultrahigh-strength dual-phase steel with high local forming performance

A technology of formability and manufacturing method, which is applied in the field of metallurgy, can solve problems such as difficulty in ensuring plate shape, increased production difficulty, and large steel plate stress, and achieve the effects of solving poor plasticity and formability, reducing component costs, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

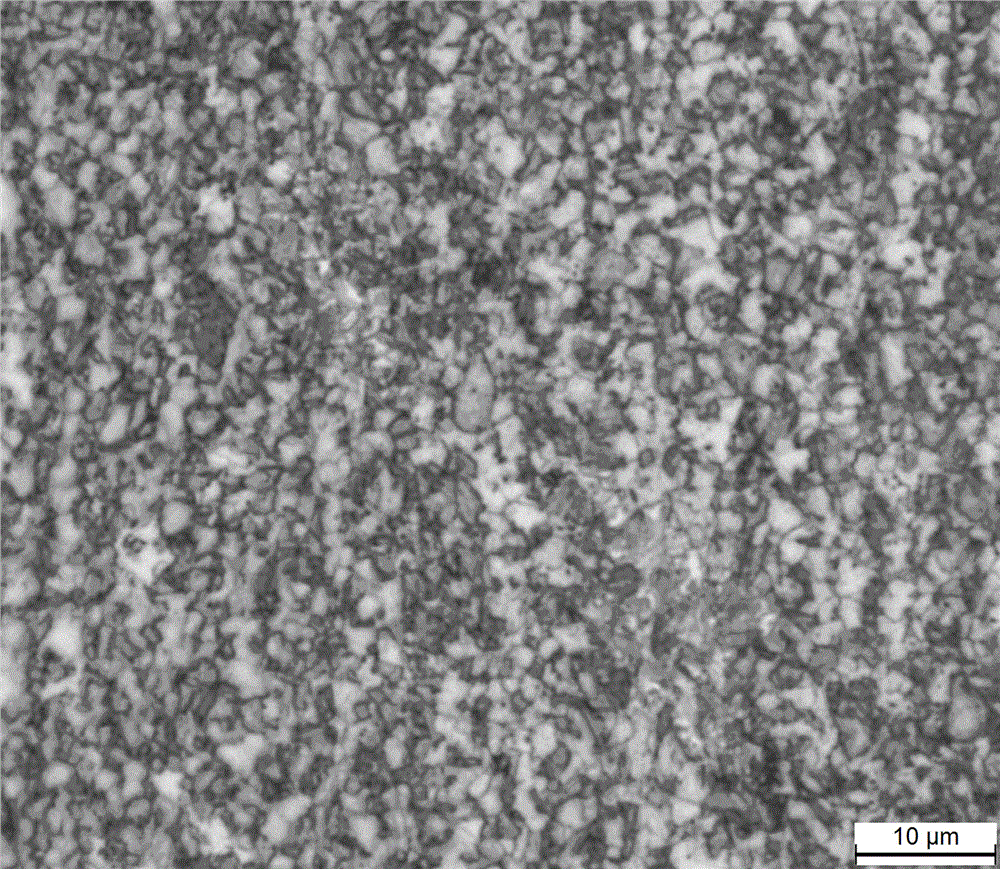

Embodiment 1

[0040] According to the percentage by weight: C0.1%, Si0.2%, Mn2.0%, Al0.04%, the rest is the chemical composition of Fe and unavoidable impurity elements to select raw materials, smelt into cast slabs; cast slabs at 1200 After heating at ℃ for 2 hours, hot rolling is carried out. The starting rolling temperature is 1150 ℃, and the final rolling temperature is 890 ℃. Hot-rolled steel plate; cold-rolled the hot-rolled steel plate after pickling, the cold-rolled reduction rate is 80%, then heated to 740°C at a heating rate of 250°C / s for annealing, and kept at 5°C / s for 3 minutes Slowly cool to 680°C at a cooling rate of 40°C / s, and then cool to 300°C at a cooling rate of 40°C / s for 5 minutes to obtain an ultra-high-strength dual-phase steel with a ferrite + martensite dual-phase structure, and the yield strength R p0.2 =650MPa, tensile strength R m =1023MPa, elongation A 50mm =12.7%, 180o bending along the rolling direction without cracking.

Embodiment 2

[0042] According to the percentage by weight: C0.11%, Si0.4%, Mn1.9%, Al0.03%, the rest is the chemical composition of Fe and unavoidable impurity elements to select raw materials and melt them into cast slabs; After heating at ℃ for 2 hours, hot rolling is carried out. The starting rolling temperature is 1120 ℃, and the final rolling temperature is 880 ℃. Hot-rolled steel plate; cold-rolled the hot-rolled steel plate after pickling, the cold-rolled reduction rate is 50%, then heated to 750°C at a heating rate of 100°C / s for annealing, and kept at 5°C / s for 2 minutes slow cooling to 650°C at a cooling rate of 60°C / s, and then cooling to 330°C at a cooling rate of 60°C / s for 5 minutes of overaging to obtain an ultra-high-strength dual-phase steel with a ferrite + martensite dual-phase structure and a yield strength of R p0.2 =665MPa, tensile strength R m =1047MPa, elongation A 50mm =12.3%, 180o bending along the rolling direction without cracking.

Embodiment 3

[0044] According to the percentage by weight: C0.09%, Si0.1%, Mn1.5%, Al0.04%, the rest is the chemical composition of Fe and unavoidable impurity elements to select raw materials and melt them into cast slabs; After heating at ℃ for 2 hours, hot rolling is carried out. The starting rolling temperature is 1130 ℃, and the final rolling temperature is 900 ℃. After rolling, it is cooled to 550 ℃ at a cooling rate of 80 ℃ / s for coiling. Hot-rolled steel plate: cold-roll the hot-rolled steel plate after pickling, the cold-rolled reduction rate is 60%, and then heat it to 780°C at a heating rate of 300°C / s for annealing, and hold it for 30s and then heat it at 3°C / s Slowly cool to 650°C at a cooling rate of 30°C / s, then cool to 300°C at a cooling rate of 30°C / s and over-age for 5 minutes to obtain an ultra-high-strength dual-phase steel with a ferrite + martensite dual-phase structure, and the yield strength R p0.2 =575MPa, tensile strength R m =987MPa, elongation A 50mm =15.6%, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com