Continuous carbonization furnace for large-size wood material

A wooden material and large-scale technology, applied in fixed carbonization furnaces, coke ovens, biofuels, etc., can solve the problems of long operation time, low production efficiency, high fuel consumption, etc., achieve continuous operation, convenient operation, increase income effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

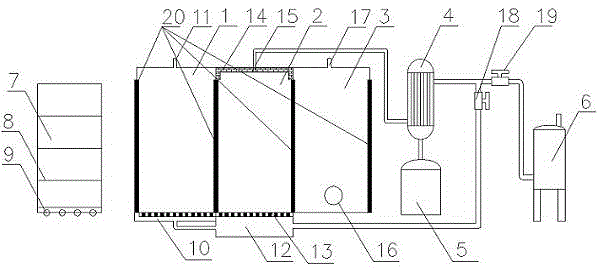

[0016] see figure 1 , a large-scale woody material continuous carbonization furnace, which is composed of a large-size woody material finishing rack 7, a preheating chamber 1, a carbonization chamber 2, a cooling chamber 3, a low-temperature condenser 4 and a smoke filter 6, the preheating The chamber 1, the carbonization chamber 2 and the cooling chamber 3 are all cuboid structures. The preheating chamber 1 and the carbonization chamber 2 share a common wall, and the carbonization chamber 2 and the cooling chamber 3 share a common wall. The carbonization chamber 2, The low-temperature condenser 4 and the flue gas filter 6 are connected in sequence through pipelines. The large-size wooden material finishing frame 7 is provided with a metal plate layer 8 and an automatic moving wheel 9, and the large-size wooden material finishing frame 7 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com