Vitrified brick gum adhesive

An adhesive and vitrified tile technology, which is applied in the field of vitrified tile back-adhesive adhesives, can solve the problems of reduced bonding strength, falling off of tiles, hollowing, etc., and achieves improved construction performance, material saving, and rapid development. Effect

Inactive Publication Date: 2016-05-04

上海亚瓦新型建筑材料有限公司

View PDF8 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the prior art, especially when used in interior and exterior walls, bathrooms and other places, due to environmental reasons, the adhesive strength between the ceramic tile and the substrate is seriously affected, resulting in reduced adhesive strength, hollowing, cracking, and tiles have fallen off

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~3

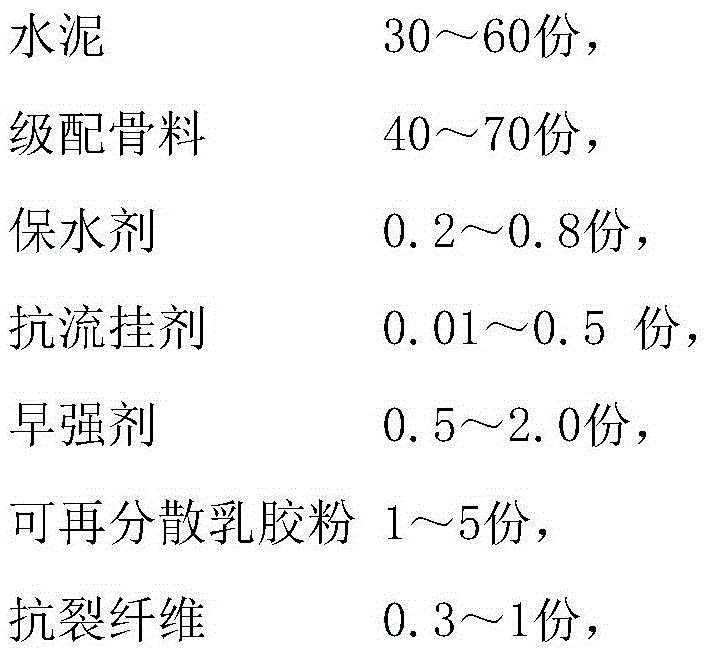

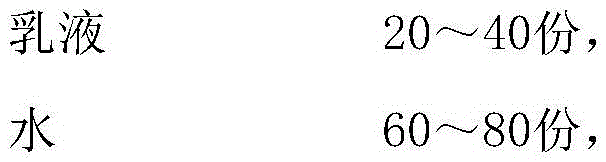

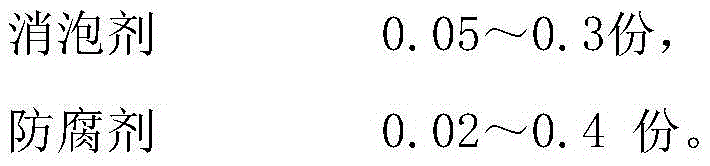

[0032] The following examples provide a vitrified tile back adhesive adhesive composition, including powders and liquids calculated in parts by weight, as shown in Table 1:

[0033] Table 1

[0034]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a vitrified brick gum adhesive, which is prepared from the following powder and liquid in parts by weight, wherein the powder is prepared from: 30-60 parts of cement, 40-70 parts of grading aggregate, 0.2-0.8 part of water-retaining agent, 0.01-0.5 part of anti-sagging agent, 0.5-2.0 parts of early strength agent, 1-5 parts of redispersible powder, 0.3-1 part of anti-cracking fiber and the liquid is prepared from: 20-40 parts of emulsion, 60-80 parts of water, 0.05-0.3 part of defoaming agent and 0.02-0.4 part of corrosion remover. By using organic combining of the ordinary Portland cement, high molecular redispersible powder and emulsion, the adhering strength of a large-sized vitrified brick is improved, the large-sized vitrified brick can be repasted to different base materials; construction performance is improved under the effect of the anti-sagging agent and operation is more convenient.

Description

technical field [0001] The invention relates to a vitrified tile back glue adhesive. Background technique [0002] The vitrified tile adhesive is composed of two parts: powder and liquid. The powder is a powdery mixture composed of cement, mineral aggregates, and organic additives. and other additives. When used, powder and liquid are mixed according to a certain ratio, and are used to pave and stick on the back of decorative materials such as large-size ceramic tiles, large-size vitrified tiles, and floor tiles. In the prior art, especially when used in places such as interior and exterior walls, bathrooms, etc., due to environmental reasons, the adhesive strength between the ceramic tile and the substrate is seriously affected, resulting in reduced adhesive strength, hollowing, cracking, and tiles have fallen off. Vitrified tile adhesive increases the bonding strength between the tile and the substrate, greatly reducing the above-mentioned quality problems. Contents of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04

CPCC04B28/04C04B2103/12C04B2103/465C04B2103/50C04B2103/60C04B2111/00637

Inventor 于全伟黄海涛

Owner 上海亚瓦新型建筑材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com