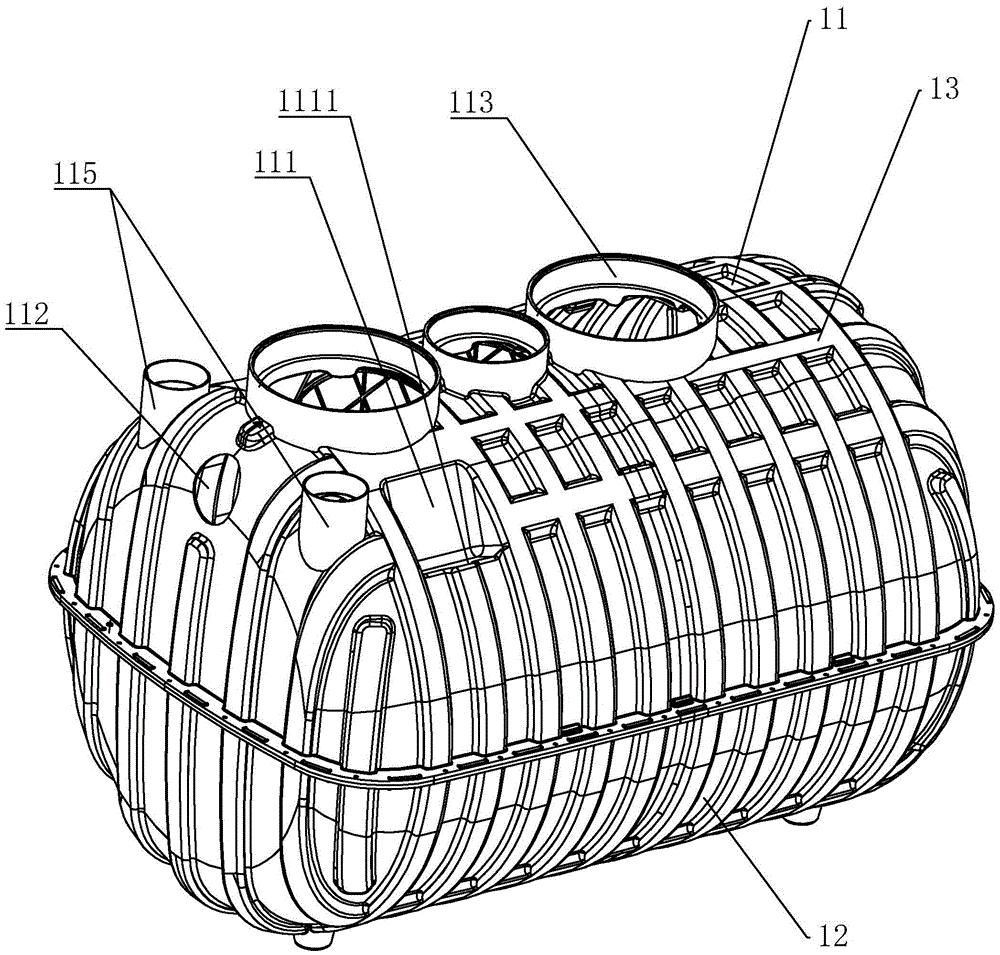

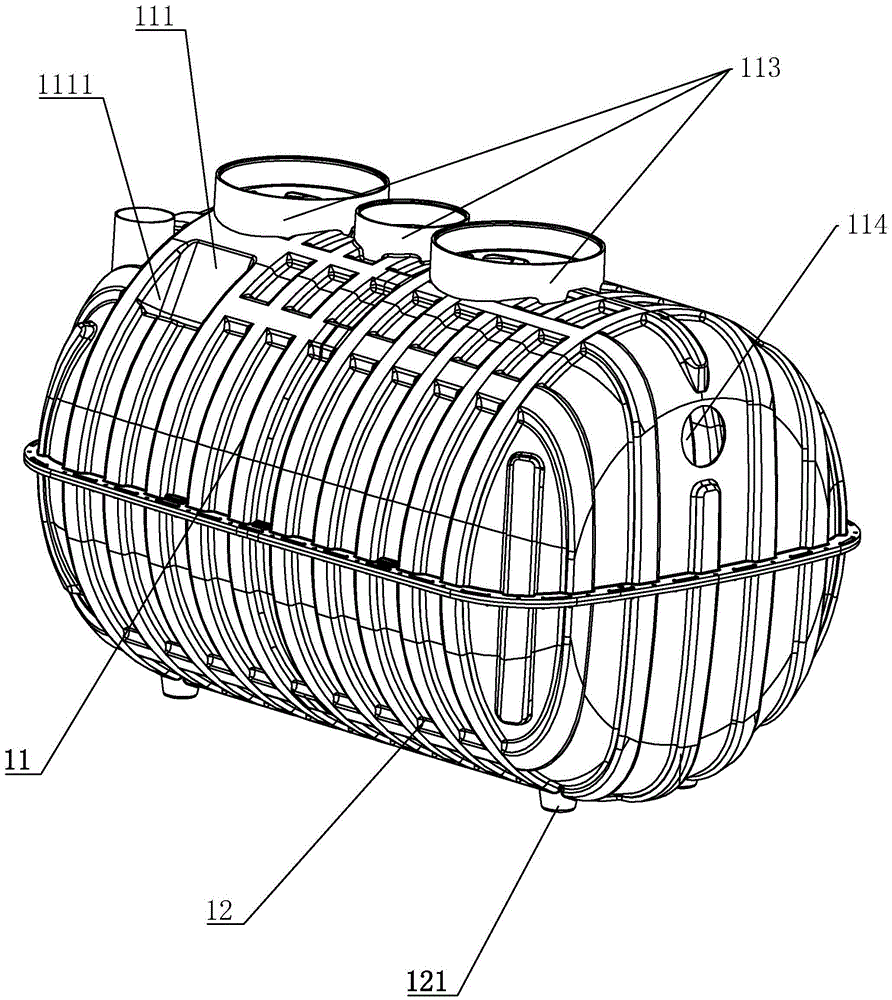

Three-cavity septic tank

A septic tank and tank body technology, applied in the field of sewage treatment equipment, can solve the problems of heavy overall structure, inability to adapt to connection, inconvenient installation, etc., and achieve the effects of cost saving, convenient processing, and optimized proportions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

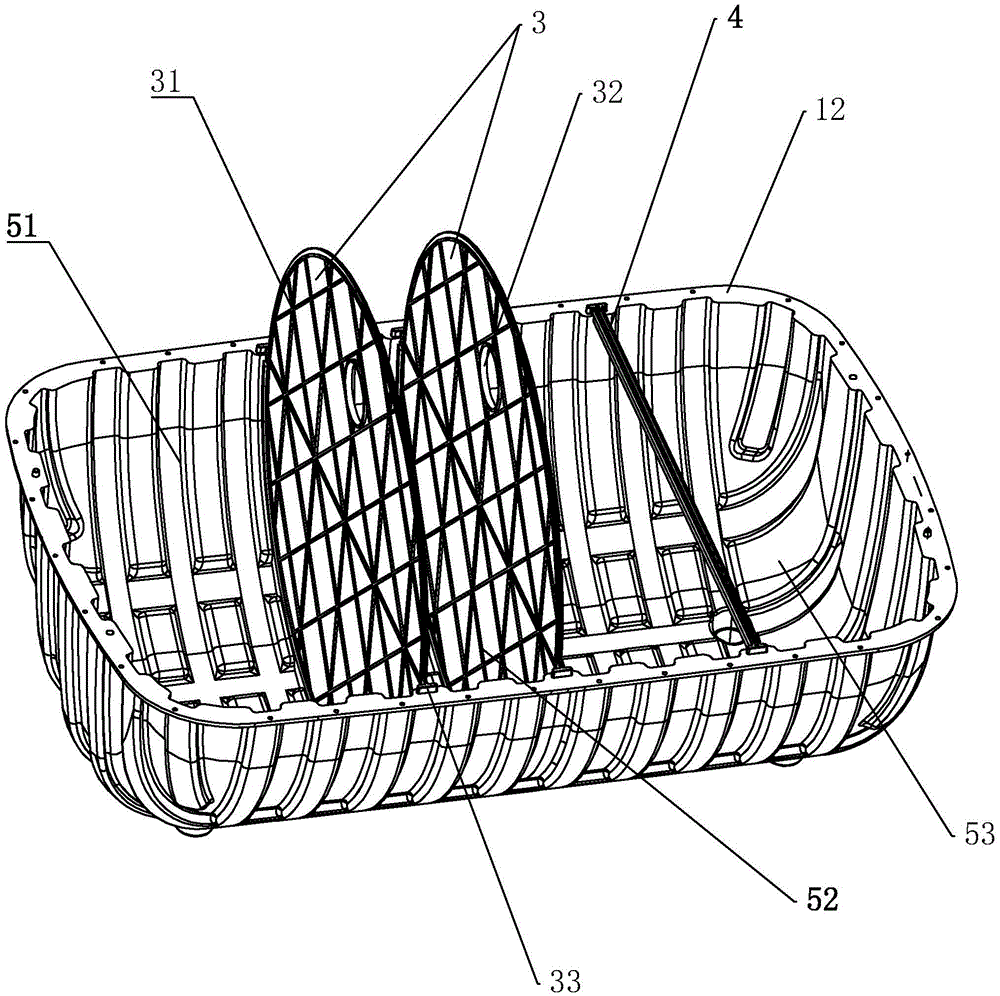

[0041] Embodiment one, as Figure 7 As shown, the cylindrical pool body is provided with a secondary sewage inlet 112, the diameter of the through hole 113 on the first cavity 51, the diameter of the through hole 113 on the second cavity 52, and the diameter of the through hole 113 on the third cavity 53. The ratio between 113 diameters is 3:1:3.

Embodiment 2

[0042] Embodiment two, such as Figure 8 As shown, there is no auxiliary sewage inlet 112 on the cylindrical pool body, the diameter of the through hole 113 on the first cavity 51, the diameter of the through hole 113 on the second cavity 52, the diameter of the through hole 113 on the third cavity 53 The ratio between the diameters of the holes 113 is 3:1:3.

Embodiment 3

[0043] Embodiment three, as Figure 9 As shown, the cylindrical pool body is provided with a secondary sewage inlet 112, the diameter of the through hole 113 on the first cavity 51, the diameter of the through hole 113 on the second cavity 52, and the diameter of the through hole 113 on the third cavity 53. The ratio between 113 diameters is 1:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com