Aluminum-rich Beta Zeolite synthesis method

A beta zeolite and aluminum-rich technology, applied in the field of molecular sieve catalytic material synthesis, can solve the problems of immature high-silicon beta zeolite synthesis technology and complicated synthesis steps, and achieve high acid density, high catalytic reaction efficiency, and inhibition of impurity crystals. produced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) First, put 16g of aluminum nitrate in a high-temperature furnace and bake it at 500°C for 3h.

[0031] (2) Take 0.27g of sodium hydroxide and 0.1g of sodium aluminate in 50mL of distilled water, stir until they are completely dissolved, then add 8g of white carbon black, and stir evenly.

[0032] (3) Mix the special alumina synthesized in step (1) with the silica-alumina gel synthesized in step (2), add 0.08g of Beta zeolite seed crystals, and dry in an oven at 110°C for 12 hours.

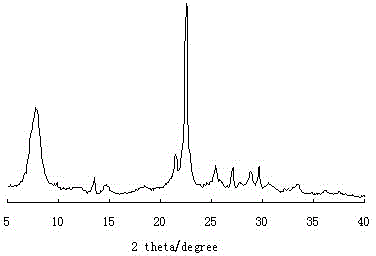

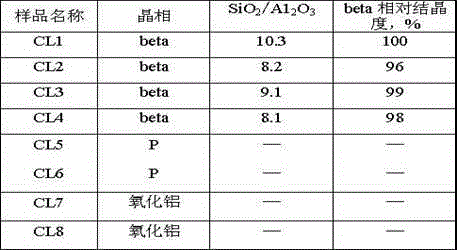

[0033] (4) Then put the dry glue obtained in step (3) into the upper part of the reactor, add 10mL of 25% ammonia water to the bottom of the reactor, put it into a closed reaction kettle, and crystallize it in an oven at 140°C for 48h. The obtained product was washed 4 times with distilled water to neutrality, and dried at 120°C for 12 hours. The obtained sample number was CL1, and the obtained sample was as follows: figure 1 As shown, it is pure beta zeolite without other impurities. ...

Embodiment 2

[0035] (1) First, put 10g of aluminum nitrate in a high-temperature furnace and bake it at 600°C for 2h.

[0036] (2) Take 0.27g of potassium hydroxide and 0.3g of aluminum nitrate in 50mL of distilled water, stir until they are completely dissolved, then add 8g of white carbon black, stir evenly, and then age at 8°C for 2 days.

[0037] (3) Mix the special alumina synthesized in step (1) with the silica-alumina gel synthesized in step (2), add 0.1g of Beta zeolite seed crystals, and dry in an oven at 120°C for 12 hours.

[0038] (4) Then put the dry glue obtained in step (3) into the upper part of the reactor, add 12mL of 20% ammonia water to the bottom of the reactor, put it into a closed reaction kettle, and crystallize it in an oven at 140°C for 40h. The obtained product was washed 4 times with distilled water until neutral, and dried at 120°C for 12 hours. The obtained sample was beta zeolite, coded as CL2.

Embodiment 3

[0040] (1) First, put 12g of aluminum nitrate in a high-temperature furnace and bake it at 700°C for 2h.

[0041] (2) Take 0.3g of sodium hydroxide and 0.35g of aluminum sulfate in 50mL of distilled water, stir until they are completely dissolved, then add 8.5g of silica gel, and stir evenly.

[0042] (3) Mix the special alumina synthesized in step (1) with the silica-alumina gel synthesized in step (2), then add 0.13g Beta zeolite seed crystals, and dry in an oven at 130°C for 12 hours.

[0043] (4) Then put the dry glue obtained in step (3) into the upper part of the reactor, add 15mL of 15% ammonia distilled water to the bottom of the reactor, put it into a closed reaction kettle, and crystallize it in an oven at 150°C for 50h. The obtained product was washed 4 times with distilled water to neutrality, and dried at 120°C for 12 hours. The obtained sample was beta zeolite, coded as CL3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com