Lifting conveying device for cigarette making machine waste smoke

A conveying device and cigarette making machine technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as unstable center of gravity, uneven belt force, and outlet blockage, so as to avoid dumping accidents and reasonable structural design , to avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

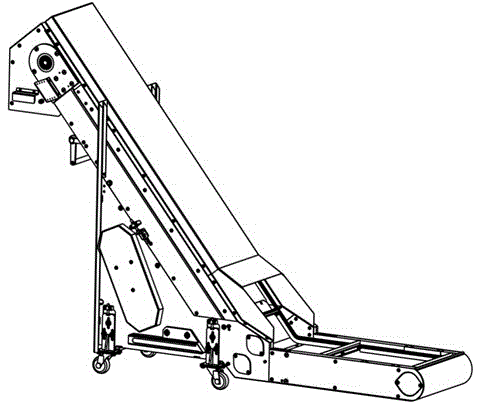

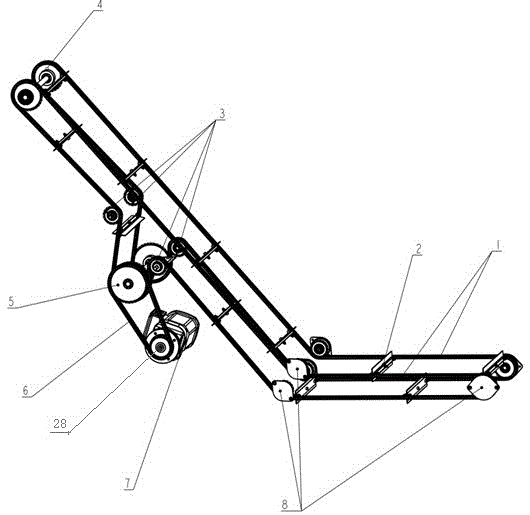

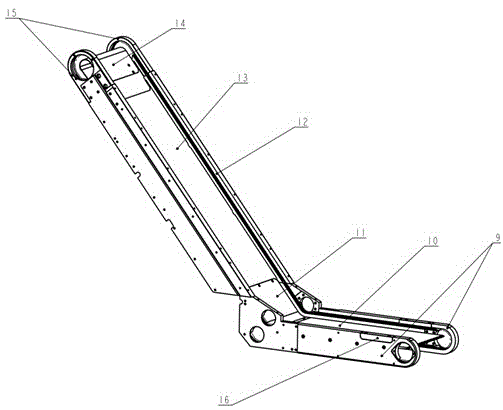

[0030] This kind of cigarette making machine waste cigarette lifting and conveying device includes a chain transmission mechanism, a guide rail mechanism and a main frame. It is characterized in that the main frame is provided with a guide rail mechanism, the main frame has a chain transmission mechanism, and the chain transmission mechanism passes through sprocket I3. , Sprocket Ⅰ4, sprocket Ⅱ5 and sprocket Ⅱ8 are connected with the main frame, and the guide rail mechanism is connected with the main frame by screws and bridge 13.

[0031] in figure 2 , image 3 , Figure 4 , Image 6 with Figure 7 The chain transmission mechanism includes chain I1, scraper assembly 2, sprocket I3, sprocket set I4, sprocket set II5, chain II6, motor 7 and sprocket II8, characterized in that the scraper assembly 2 is connected to the chain by screws The motor 7 is connected to the chain II 6 through the sprocket 28, and the chain II 6 is connected to the chain I1 through the sprocket set 5. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com