Wide-range lateral-scanning type draught detection system and working method thereof

A technology of detection system and working method, which is applied to the equipment for increasing the stability of ships, ships, and equipment for reducing the movement of ships, etc. The effect of convenient maintenance, improved measurement accuracy, and increased measurement points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention will be further described:

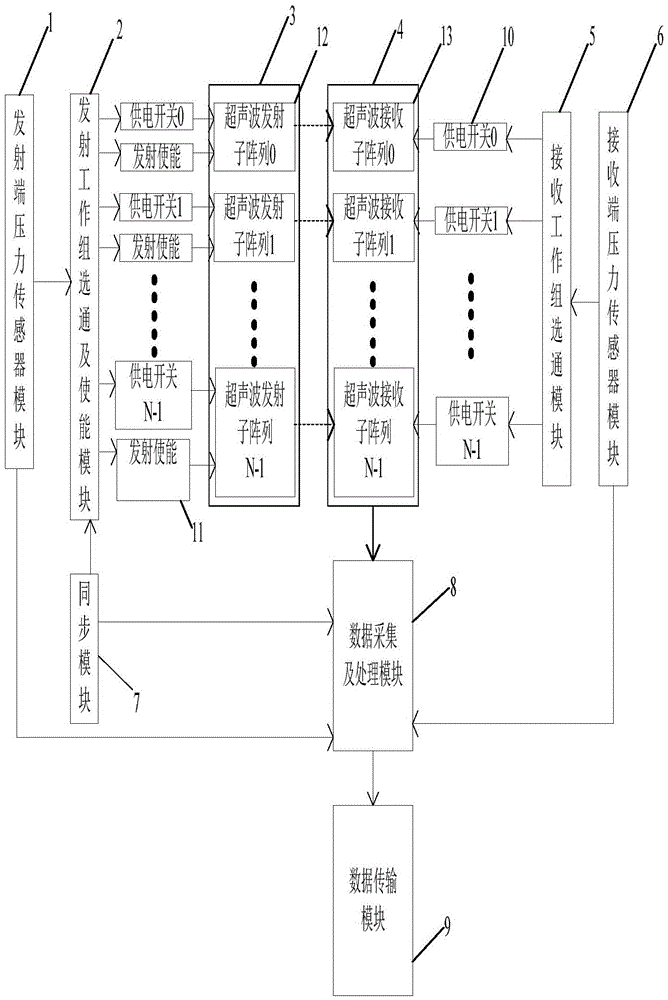

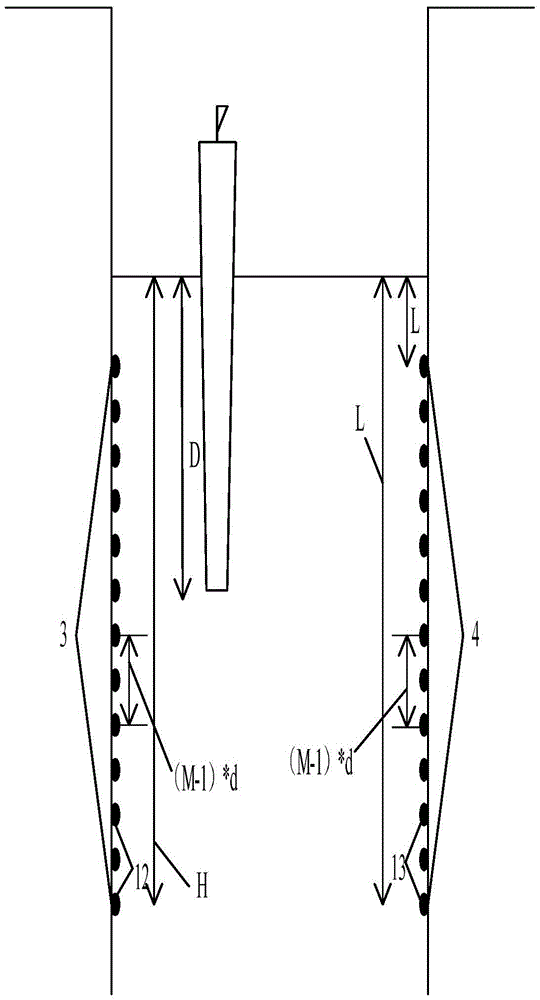

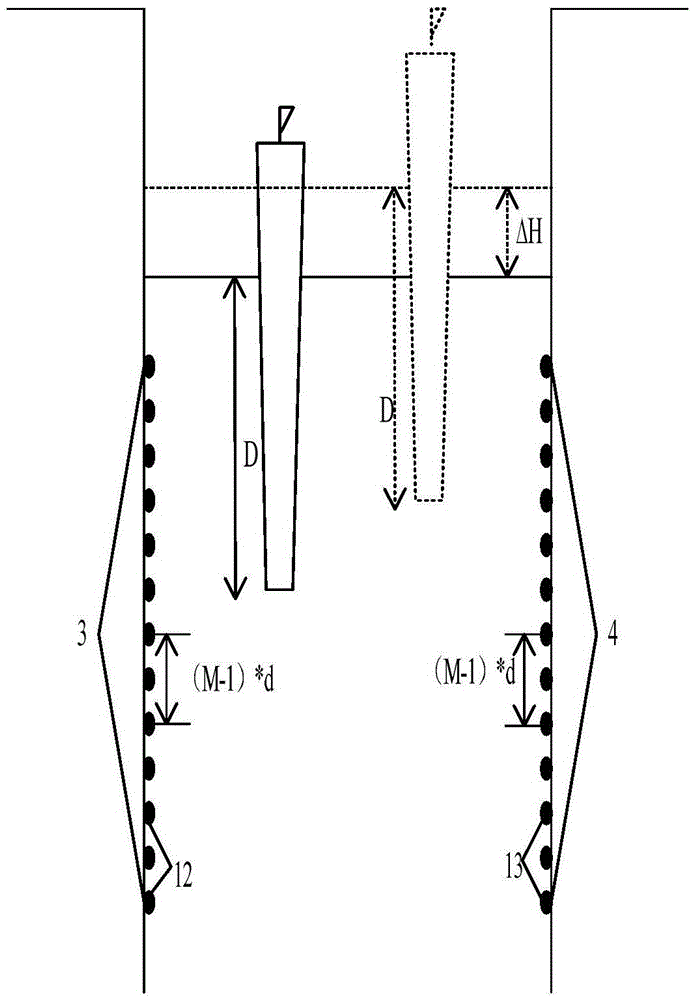

[0039]A wide-range side-sweep type draft detection system, including a transmitter pressure sensor module 1, a transmitter working group gating and enabling module 2, a synchronization module 7, an ultrasonic transmitter module 3, a receiver pressure sensor module 6, a receiver working group selection Communication module 5, ultrasonic receiving module 4, data acquisition and processing module 8 and data transmission module 9; described data acquisition and processing module 8 communicates with ultrasonic receiving module 4, transmitting end pressure sensor module 1, receiving end pressure sensor through data line Module 6, data transmission module 9, synchronous module 7 are connected; Described synchronous module 7 is gated and enabled module 2, data acquisition and processing module 8 are connected with launching group working group by data line; Described receiving work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com