Novel instrument board beam assembly of blade electric vehicles

A pure electric vehicle and crossbeam assembly technology, which is applied to the upper structure sub-assembly, vehicle parts, upper structure, etc., can solve the problems of complex fixture design, poor welding quality, and low welding efficiency, and achieve a good installation and matching relationship , Improve welding quality, reduce the effect of defective parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

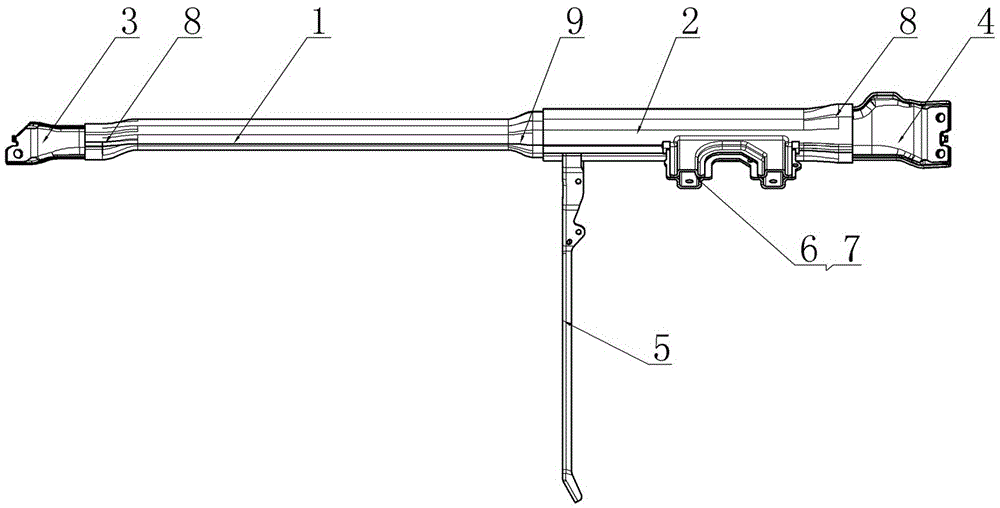

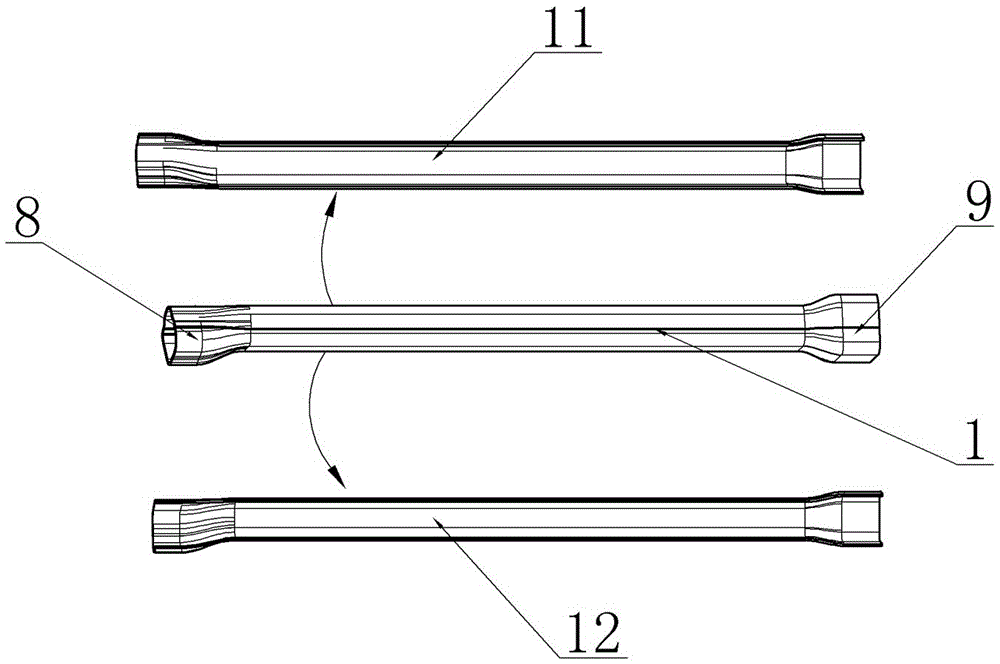

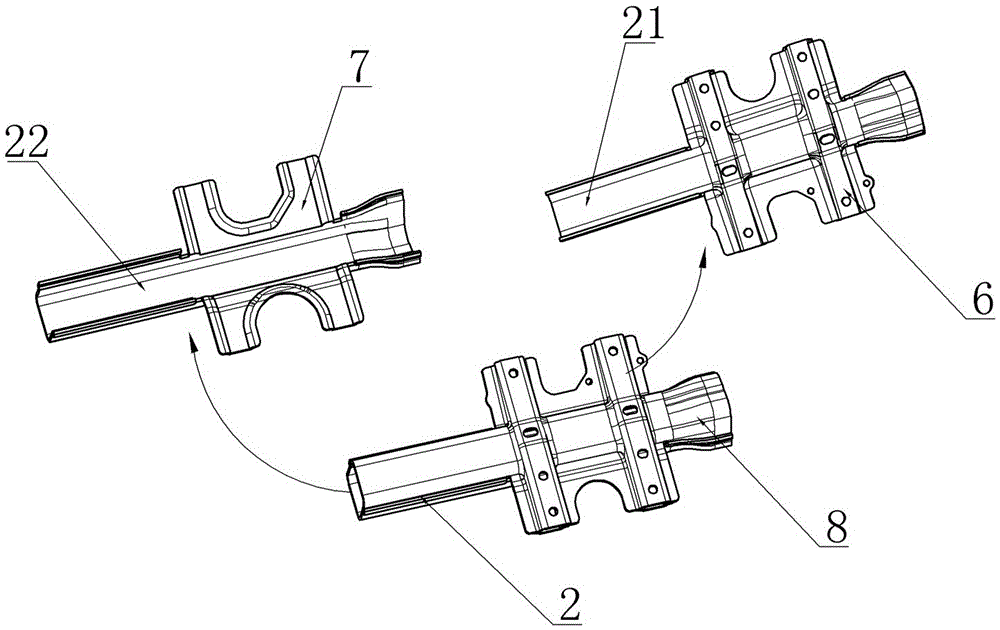

[0027] see Figure 1-Figure 6 , a new instrument panel crossbeam assembly for a pure electric vehicle, comprising a crossbeam body, a left instrument panel crossbeam connecting plate 3 arranged at the left end of the crossbeam body, a right instrument panel crossbeam connecting plate 4 arranged at the right end of the crossbeam body, and a fixed The longitudinal arm beam 5 is arranged in the middle of the beam body. The beam body includes a left tube beam 1 and a right tube beam 2 which are fixedly fitted and sleeved. The left pipe beam 11 and the lower left pipe beam 12, the right pipe beam 2 includes an upper right pipe beam 21 and a lower right pipe beam 22 in a U-shaped groove shape with opposite openings, at the right end of the left pipe beam There is an inner socket transition section 9 that matches and fits the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com