Robot for greening pruning

A robot and robotic arm technology, applied in the field of green trimming robots, can solve the problems of low energy utilization, low automation, long trimming time, etc., to achieve broad market demand and development space, huge social and economic benefits, increase The effect of agency operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

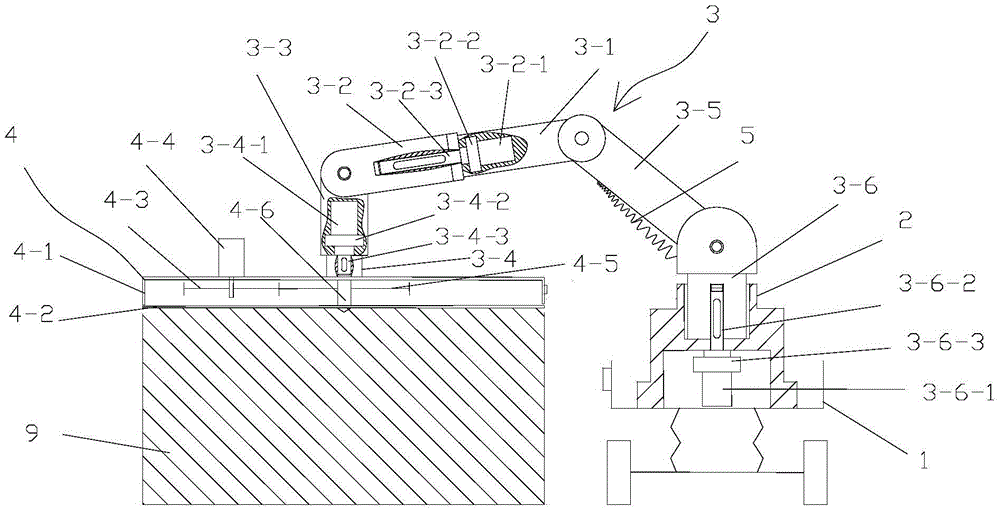

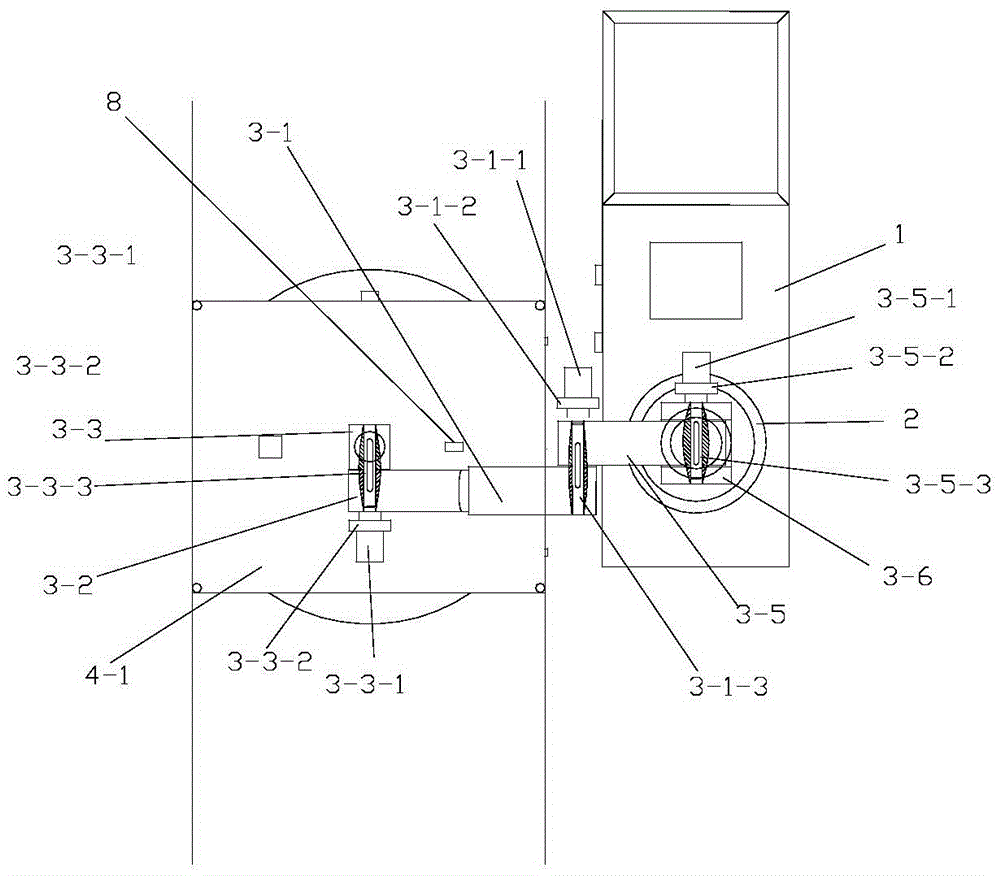

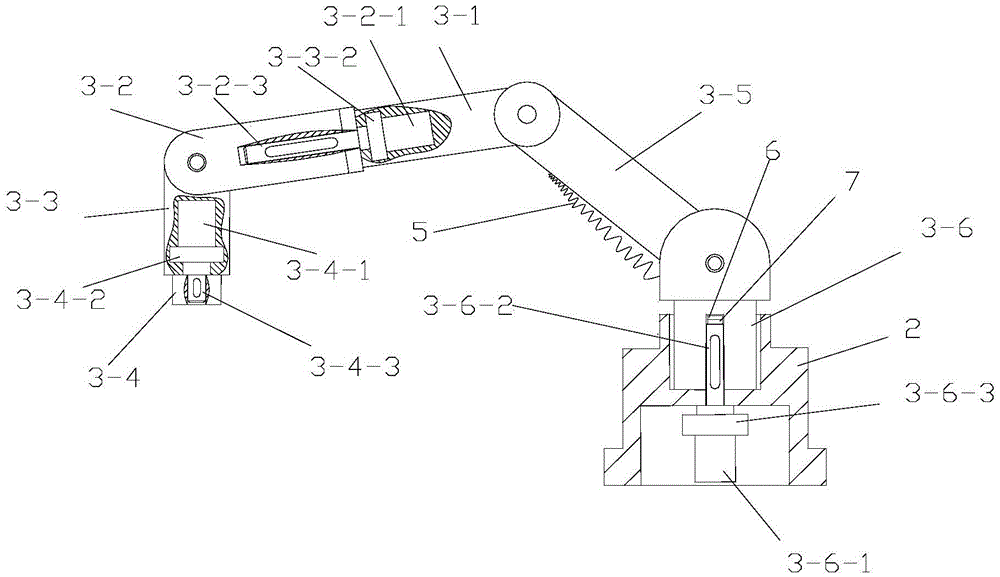

[0025] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 top view, image 3 It is a schematic diagram of the mechanical arm structure in the present invention, Figure 4 As shown in the figure, the pruning actuator structure schematic diagram in the present invention: the greening and pruning robot of this embodiment includes a walkable car body 1 and a base 2 arranged on the walkable car body 1, and also includes a mechanical arm 3 and a set trimming actuator 4 at the end of the robotic arm 3;

[0026] The mechanical arm 3 includes an upper arm assembly and a lower arm assembly that is arranged in cooperation with the base 2 in a manner that can rotate in a horizontal plane. The upper arm assembly includes an upper arm 3-1 and a terminal drive arm assembly. The upper arm 3-1 can be rotated vertically. It is connected to the end of the lower arm assembly by rotating in a straight plane. The end drive arm assembly includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com