Lyophilized Citrus reticulata powder capsule product

A technology of citrus and freeze-drying, which is applied in the food field and can solve problems such as complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

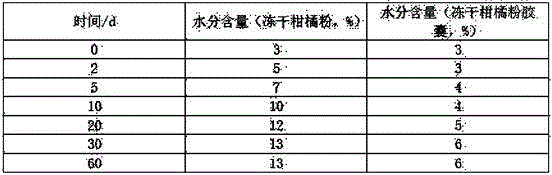

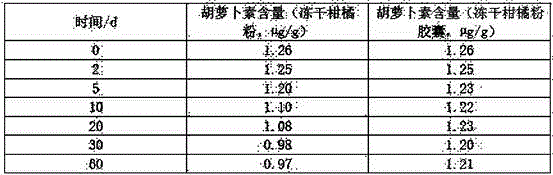

Embodiment 1

[0020] Select fresh and ripe citrus, transfer it to a sterile clean area, manually remove the orange peel, divide it into individual orange petals, and pick off the orange network. The cleaned orange segments were stirred at 1500r / min for 8min, then transferred to a centrifuge and centrifuged at 2500rpm for 10min, and finally filtered with a 20-mesh filter to remove solid matter. The citrus slurry obtained after filtering was drained and intercooled in a fume hood at 15° C. for 50 minutes. After draining, it was evenly spread in stainless steel freeze-drying trays and put into a drying box of a freeze dryer. When the temperature of the material reaches below -30°C and the temperature of the cold trap reaches below -40°C, the vacuum pump is turned on, and when the vacuum degree reaches 450Pa, the gradient temperature of the separator begins. -30°C for 2h→-25°C for 2h→-20°C for 1.5h→-15°C for 1.5h→heat to 50°C for 10h. During the heating process, the vacuum pressure of the dryi...

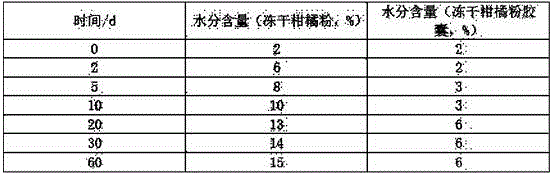

Embodiment 2

[0024] Select fresh and ripe citrus, transfer it to a sterile clean area, manually remove the orange peel, divide it into individual orange petals, and pick off the orange network. The cleaned orange segments were stirred at 2000r / min for 5min, then transferred to a centrifuge and centrifuged at 2000rpm for 15min, and finally filtered with a 30-mesh filter to remove solid matter. The citrus slurry obtained after filtering was drained and intercooled in a fume hood at 20° C. for 30 minutes. After draining, it was evenly spread in stainless steel freeze-drying trays and put into the drying box of the freeze dryer. When the temperature of the material reaches below -32°C and the temperature of the cold trap reaches below -40°C, the vacuum pump is turned on, and when the vacuum degree reaches 420Pa, the gradient temperature of the separator begins. -32°C for 1.5h→-25°C for 1.5h→-20°C for 2h→-15°C for 2h→heat to 50°C for 12h. During the heating process, the vacuum pressure of the ...

Embodiment 3

[0028] Select fresh and ripe citrus, transfer it to a sterile clean area, manually remove the orange peel, divide it into individual orange petals, and pick off the orange network. The cleaned orange segments were stirred at 1000r / min for 10min, then transferred to a centrifuge and centrifuged at 3000rpm for 5min, and finally filtered with a 10-mesh filter to remove solid matter. The citrus slurry obtained after filtering was drained and intercooled in a fume hood at 10° C. for 60 minutes. After draining, it was evenly spread in stainless steel freeze-drying trays and put into a drying box of a freeze dryer. When the temperature of the material reaches below -35°C and the temperature of the cold trap reaches below -45°C, the vacuum pump is turned on, and when the vacuum degree reaches 400Pa, the gradient temperature of the separator begins. -35°C for 1.5h→-20°C for 1.5h→-15°C for 1h→-10°C for 1h→heat to 50°C for 15h. During the heating process, the vacuum pressure of the dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com