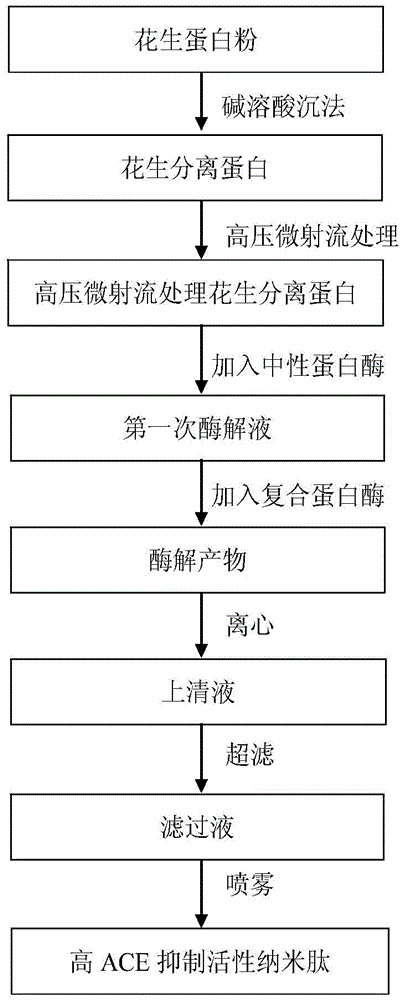

Preparation method of peanut nano peptide

A nano and peanut technology, applied in protein-containing food ingredients, protein food processing, vegetable protein processing, etc., to improve the efficiency of enzymatic hydrolysis and reduce the cost of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Step 1: Weigh 150g of peanut protein powder, add 1500mL of deionized water to prepare a 10% (w / v) concentration solution, adjust the pH value to 8.0, stir and dissolve for 120min, and centrifuge at 4000rpm for 15min; take the supernatant and adjust the pH value to 4.5, set aside for 60 minutes; centrifuge at 4000rpm for 15 minutes; take the precipitate, add water to dissolve, adjust the pH value to 7.0, stir and dissolve for 120 minutes; spray dry to obtain peanut protein isolate;

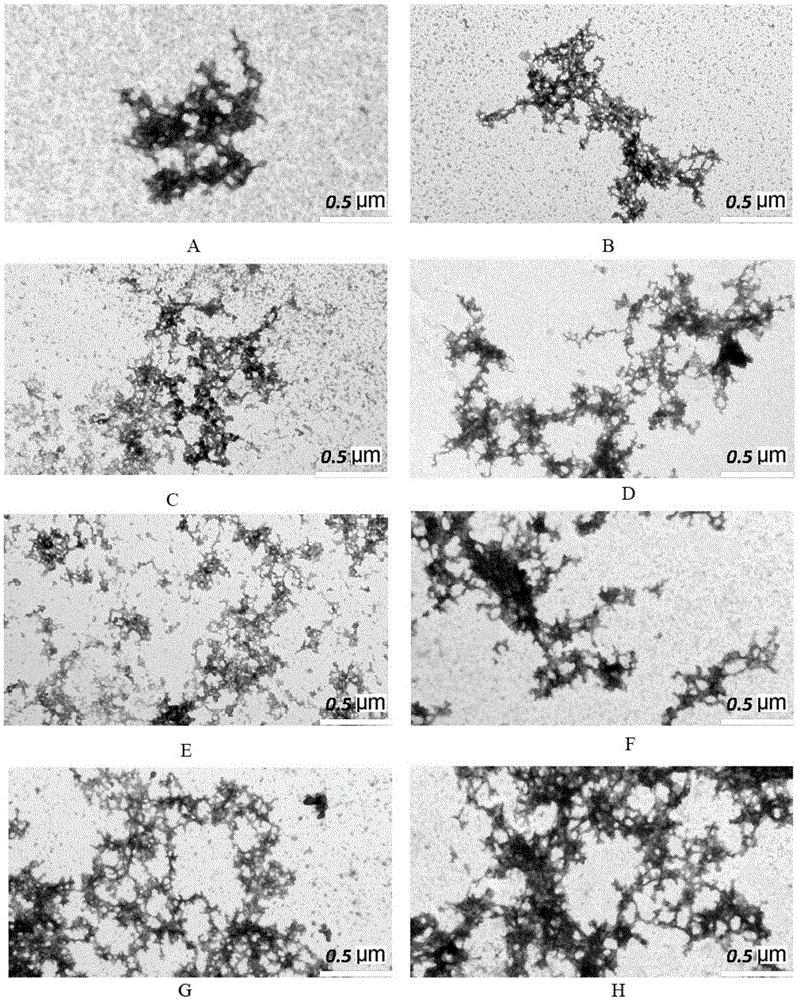

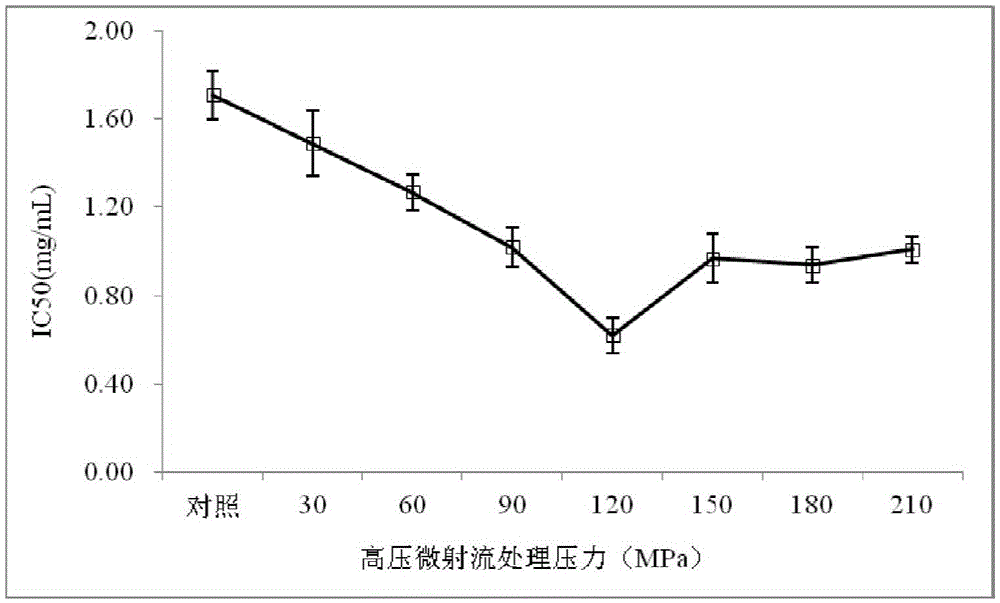

[0052] Step 2: Weigh 60g of the spray-dried peanut protein isolate, add 1000mL of deionized water to prepare a 6% (w / v) solution, stir and dissolve for 60min; turn on the micro-jet ultra-high pressure homogenizer, and take 100mL peanut protein isolate solution , without applying pressure, put it into the equipment, take the effluent, as a control; then, take samples of 100mL solution in turn as 7 different pressure treatment groups, respectively at 30MPa, 60MPa, 90MPa, 120MPa, 150MPa, 180MPa,...

Embodiment 2

[0054] Example 2 Effects of different pressure treatments on the molecular weight and ACE inhibitory activity of peanut short peptides.

[0055] Step 1: Weigh 300g of peanut protein powder, add 3000mL of deionized water to prepare a 10% (w / v) concentration solution, adjust the pH value to 8.0, stir and dissolve for 120min, and centrifuge at 4000rpm for 15min; take the supernatant and adjust the pH value to 4.5, set aside for 60 minutes; centrifuge at 4000rpm for 15 minutes; take the precipitate, add water to dissolve, adjust the pH value to 7.0, stir and dissolve for 120 minutes; spray dry to obtain peanut protein isolate;

[0056] Step 2: Weigh 120g of the spray-dried peanut protein isolate, add 2000mL of deionized water to prepare a 6% (w / v) solution, stir and dissolve for 60min; turn on the micro-jet ultra-high pressure homogenizer, and take 150mL of the peanut protein isolate solution , without applying pressure, put it into the equipment, take the effluent, as a control; ...

Embodiment 3

[0064] Example 3 The influence of high-pressure micro-fluidic treatment and the concentration of the control enzymatic hydrolysis material.

[0065] Step 1: Weigh 100g of peanut protein powder, add 1000mL of deionized water to prepare a 10% (w / v) concentration solution, adjust the pH value to 8.0, stir and dissolve for 120min, and centrifuge at 4000rpm for 15min; take the supernatant and adjust the pH value to 4.5, set aside for 60 minutes; centrifuge at 4000rpm for 15 minutes; take the precipitate, add water to dissolve, adjust the pH value to 7.0, stir and dissolve for 120 minutes; spray dry to obtain peanut protein isolate;

[0066] Step 2: Weigh 45g of the spray-dried peanut protein isolate, add 750mL of deionized water to prepare a 6% (w / v) solution, stir and dissolve for 60min; turn on the micro-jet ultra-high pressure homogenizer, and take 750mL of the peanut protein isolate solution , Circulate 3 times under the pressure of 120MPa, and take the effluent. Dry the efflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com