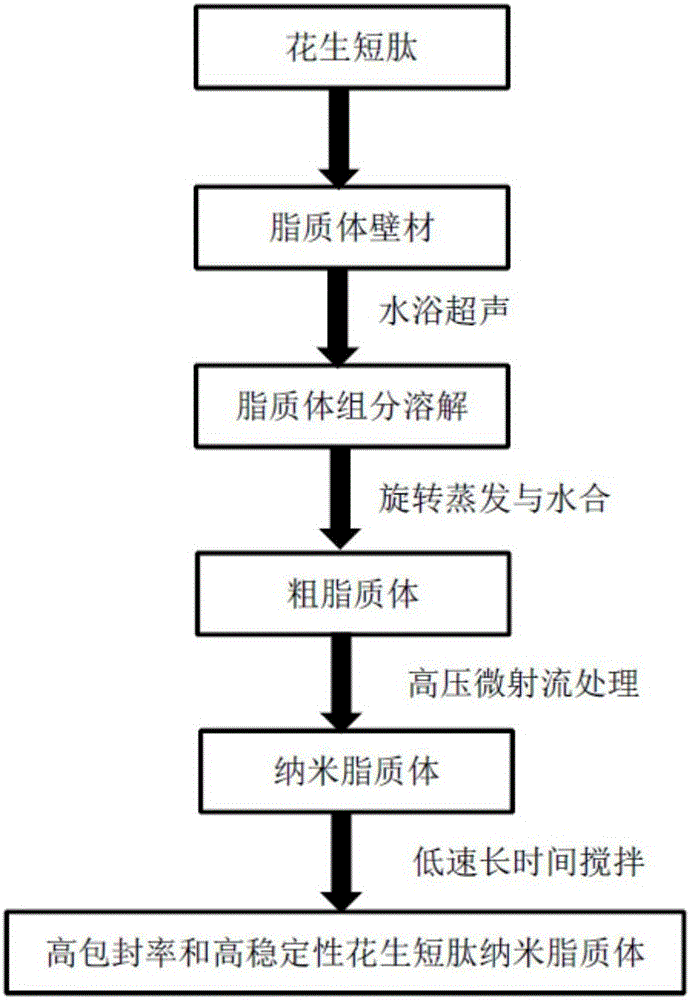

Peanut oligopeptide-coated nano liposome as well as preparation method and application thereof

A nano-liposome and short peptide technology, which is applied in the directions of liposome delivery, peptide/protein components, medical preparations of inactive ingredients, etc., can solve problems such as low encapsulation rate, and achieve low cost and simple preparation process. , the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Example 1 The effect of different pressure treatments of high-pressure microjet on liposome particle size and encapsulation efficiency

[0078] Step 1: Weigh 421 mg of lecithin, 36.7 mg of peanut short peptide, 44.2 mg of cholesterol, 95.7 mg of sodium deoxycholate, add 100 mL of 95% ethanol, and sonicate in a water bath until it is completely dissolved;

[0079] The second step: depressurize the solution in a water bath at 45°C, and remove the ethanol by rotary evaporation, with a vacuum of -0.09MPa, until a uniform lipid film is formed on the wall of the eggplant bottle. Add 100 mL of 0.01 mol / L PBS (pH 7.4) buffer to the rotary evaporating flask, spin and hydrate for 60 minutes to obtain a crude liposome suspension;

[0080] The third step: pass the crude liposome suspension through a high-pressure micro-jet homogenizer, and the treatment pressure is 60, 90, 120, 150, and 180 MPa, respectively, and cycle treatment once to determine the liposome particle size and encapsulati...

Embodiment 2

[0084] Example 2 The effect of different cycles of high-pressure micro-jet 120MPa treatment on liposome particle size and encapsulation efficiency

[0085] Step 1: Weigh 421 mg of lecithin, 36.7 mg of peanut short peptide, 44.2 mg of cholesterol, 95.7 mg of sodium deoxycholate, add 100 mL of 95% ethanol, and sonicate in a water bath until it is completely dissolved;

[0086] The second step: depressurize the solution in a water bath at 45°C, and remove the ethanol by rotary evaporation, with a vacuum of -0.09MPa, until a uniform lipid film is formed on the wall of the eggplant bottle. Add 100 mL of 0.01 mol / L PBS (pH 7.4) buffer to the rotary evaporating flask, spin and hydrate for 60 minutes to obtain a crude liposome suspension;

[0087] The third step: pass the crude liposome suspension through a high-pressure micro-jet homogenizer at a treatment pressure of 120 MPa, and cycle treatment for 1-5 times to determine the liposome particle size and encapsulation efficiency of different...

Embodiment 3

[0090] Example 3 The effect of Ostwald maturation of nanoliposomes on the encapsulation efficiency

[0091] Step 1: Weigh 421 mg of lecithin, 36.7 mg of peanut short peptide, 44.2 mg of cholesterol, 95.7 mg of sodium deoxycholate, add 100 mL of 95% ethanol, and sonicate in a water bath until it is completely dissolved;

[0092] The second step: depressurize the solution in a water bath at 45°C, and remove the ethanol by rotary evaporation, with a vacuum of -0.09MPa, until a uniform lipid film is formed on the wall of the eggplant bottle. Add 100 mL of 0.01 mol / L PBS (pH 7.4) buffer to the rotary evaporating flask, spin and hydrate for 60 minutes to obtain a crude liposome suspension;

[0093] The third step: pass the crude liposome suspension through a high-pressure micro-jet homogenizer at a treatment pressure of 120 MPa, and perform 4 cycles of treatment to obtain nano liposomes;

[0094] The fourth step: stir the nanoliposomes at 20, 50, and 100 rpm under room temperature condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com