Continuous sugar cooking device

A technology of boiling sugar and stirring shafts, which is applied in the fields of confectionery, confectionary industry, food science, etc. It can solve problems such as incomplete reverse of caramelization, uneven mixing of sugar materials, excessive reaction of caramelized flowers, etc., to avoid caramelization Insufficient aroma, faster evaporation, and better quality of boiled sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

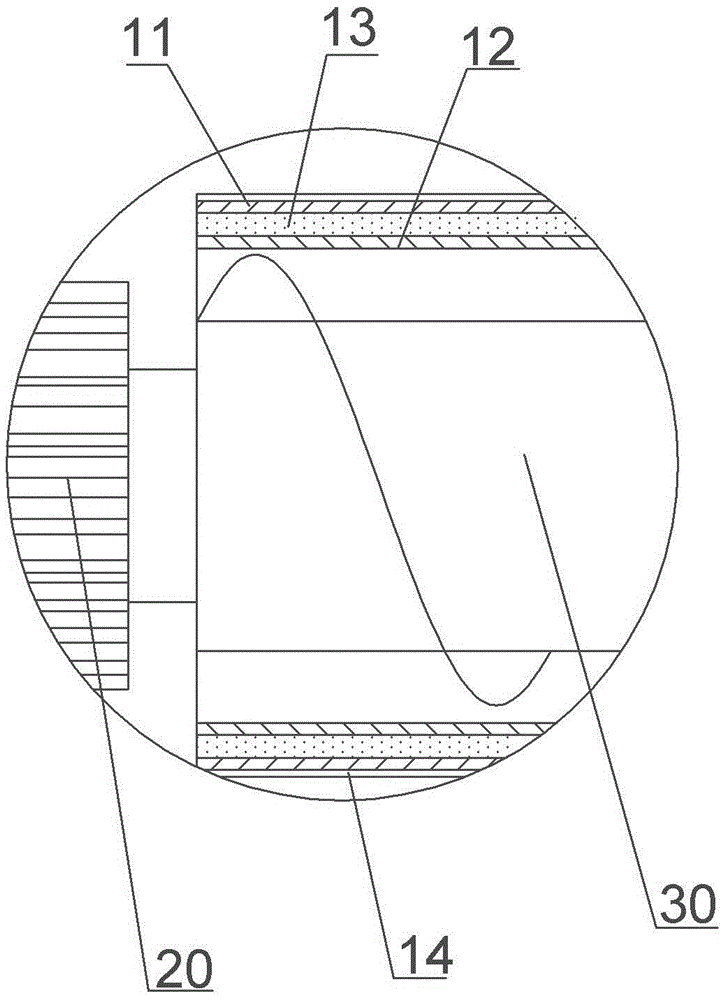

[0014] The reference signs in the accompanying drawings of the description include: outer wall 11 , inner wall 12 , interlayer 13 , insulation layer 14 , motor 20 , stirring shaft 30 .

[0015] The embodiment is basically as attached figure 1 Shown: a continuous sugar boiling device, including a sugar boiling tube, a motor 20, a stirring shaft 30 and a controller. There is a feeding port on the sugar boiling tube, the feeding end of the sugar boiling tube is connected to the output shaft of the motor 20 in rotation, the output end of the motor 20 is connected to the stirring shaft 30 through a coupling, the stirring shaft 30 is welded with blades, and the blades are continuous spiral The blade, the continuous spiral blade can not only play a good stirring role, but also can play a conveying role, sending the sugar material away from the sugar boiling tube as soon as poss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com