Ultrasonic lobster cleaning machine

An ultrasonic and cleaning machine technology, which is applied in shrimp/lobster processing, spraying devices, liquid spraying devices, etc., can solve the problems of low work efficiency, high cost, harmful to human health, etc., and achieve high cleaning efficiency, high cleaning degree, The effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

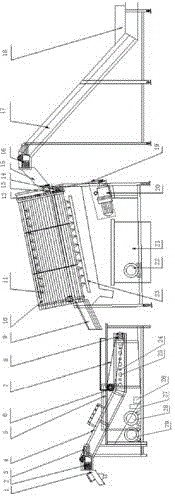

[0016] see figure 1 , an ultrasonic lobster cleaning machine, including a lifting conveying mechanism, a primary cleaning mechanism and a secondary cleaning mechanism; the lifting conveying mechanism includes a feeding plate 15, a second motor 16, a feeding track 17 and a storage box 18, and the feeding plate 15 and the storage box 18 are respectively positioned at the two ends of the feeding crawler belt 17, the second motor 16 is driven to connect the feeding crawler belt 17, the lobster is placed in the storage box 18, and the second motor 16 drives the feeding crawler belt 17 to store the food to be washed in the storage box 18. The prawns are transported upwards in the feeding plate 15;

[0017] Described primary cleaning mechanism comprises material guide plate 9, hexagonal bar screen 10, the 3rd sprocket wheel 14, the 2nd chain 19, the 3rd ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com