Built-in permanent magnet motor rotor structure and motor with same

A rotor structure, permanent magnet motor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit, etc., can solve the problems of reducing cogging torque and torque ripple, etc., to achieve reduction Effects of cogging torque and torque ripple, weakening of cogging torque and torque ripple, and improvement of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

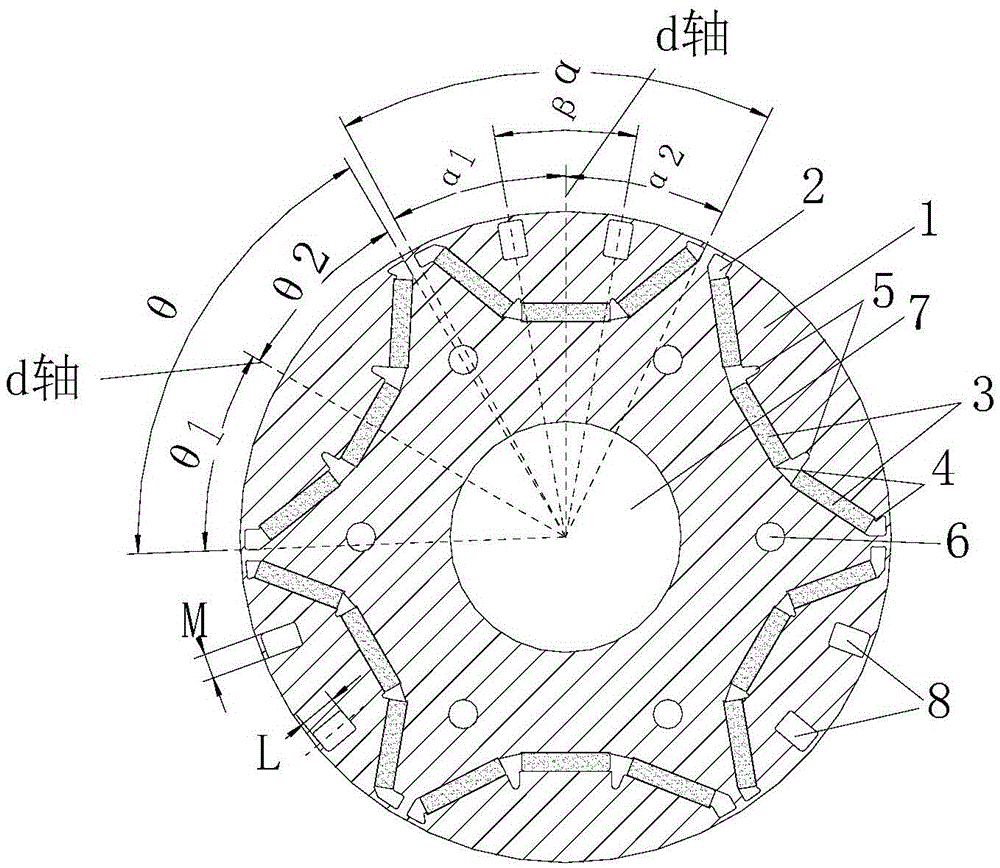

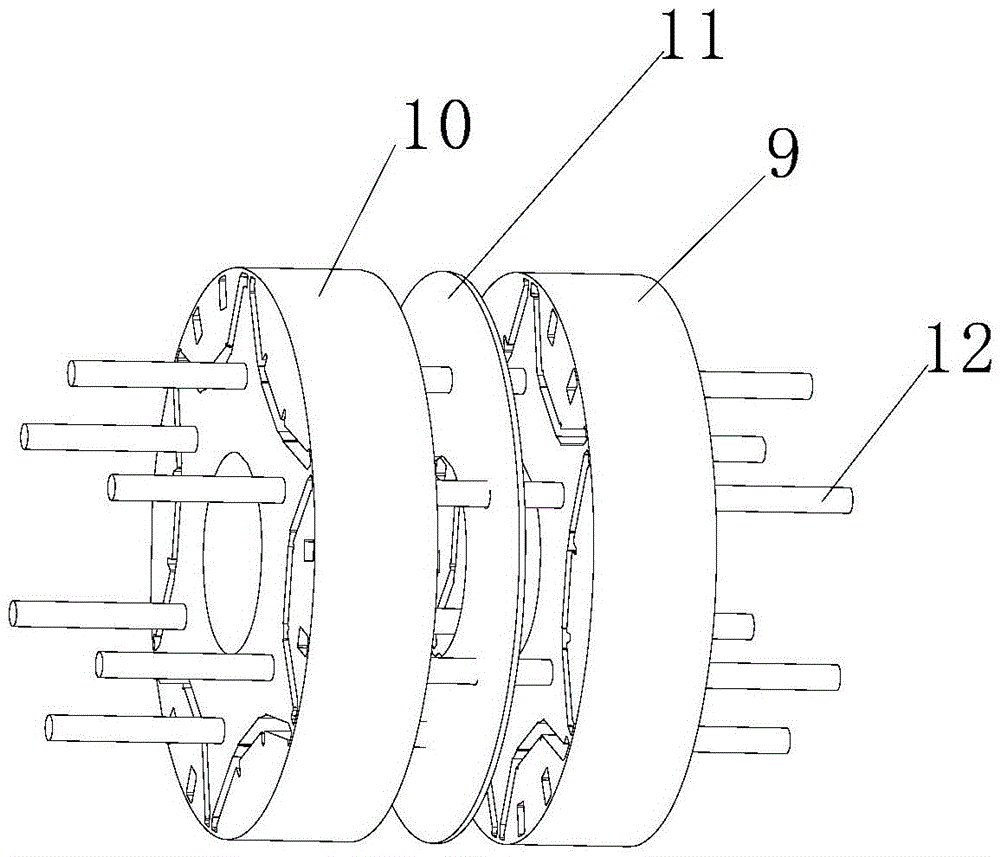

[0033] like Figure 1-3 As shown, the present invention provides a built-in permanent magnet motor rotor structure, including a rotor punch 1 (preferably a silicon steel sheet material) and a magnet 3 (preferably a magnetic steel) disposed inside the rotor punch 1 A plurality of magnetic slots 2, and shaft holes 7 pole rivet holes 6 matched with the rotating shaft, wherein the configuration of the N and S magnetic poles under a pair of rotor poles is different, defining the pole arc angle of the two magnetic poles under a pair of poles of the rotor structure They are the first pole arc angle α and the second pole arc angle θ respectively. The pole arc angle can be changed by setting asymmetric magnetic isolation holes near the end of the outer circular magnetic steel groove of the rotor. The first pole arc angle α is determined by the magnetic pole where it is located. The d-axis of the centerline is divided into α1 and α2 (α1 and α2 under the same pole satisfy: α1+α2=α), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com