Slab-yard tracking and management system

A management system and slab storage technology, applied in the field of slab tracking and management system in slab storage, can solve the problems of wrong slab loading, wrong placement, etc., to improve product quality, reduce quality objection, correctness and real-time The effect of sexual assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

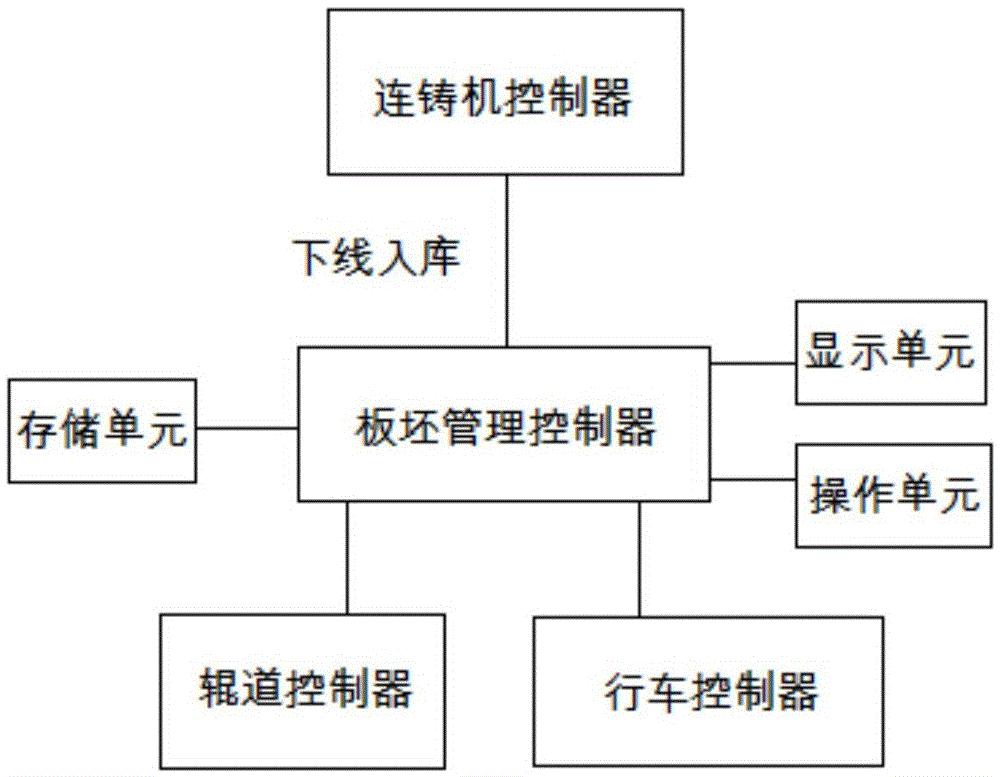

[0033] Such as figure 1 As shown, the slab warehouse tracking and management system mainly includes a continuous casting machine controller, a slab management controller, a roller table controller, a driving controller, a storage unit, an operation unit and a display unit.

[0034] The controller of the continuous casting machine is used to control the work of the continuous casting machine. It is connected to this system to output the slab off-line and storage information, that is, when the continuous casting machine cuts a slab, the continuous casting machine controller will send the to send a message.

[0035] The slab management controller is the core of the whole system, coordinates the control of each controller, receives the slab off-line storage information, and outputs the storage operation instructions to the driving controller and roller table controller. The slab management controller can not only coordinate and control The slab storage can also coordinate the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com