Oil seal for steering column of automobile

An automobile steering column and steering column technology, applied in the field of parts and components, can solve problems such as oil leakage, many parts, complicated process, etc., and achieve the effect of reducing process steps, good effect and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

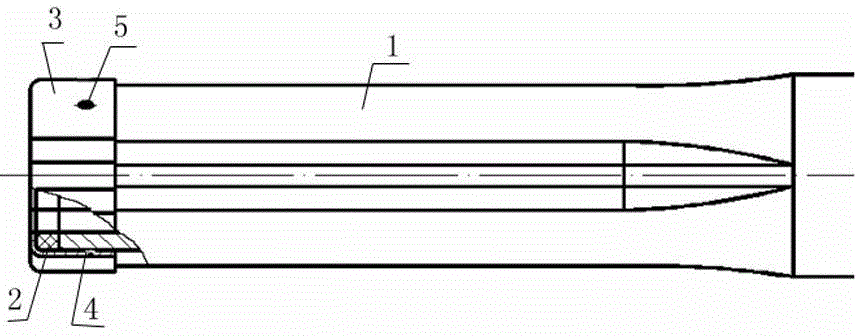

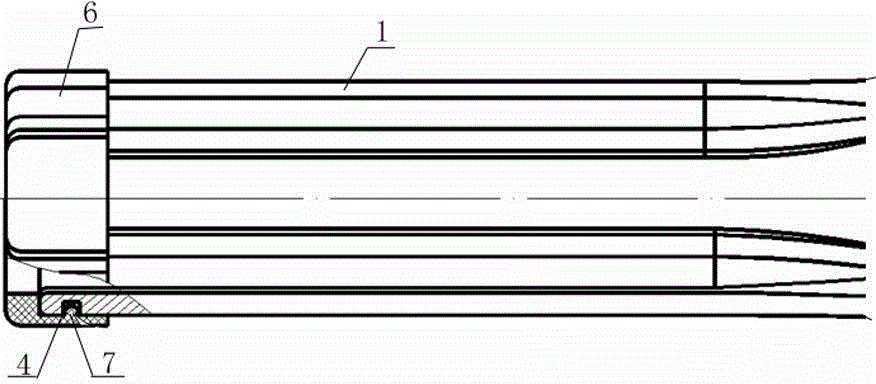

[0012] The present invention as figure 2 shown.

[0013] The oil seal for the steering column of an automobile includes a steering column 1, a fixed groove 4 is provided on the journal of the steering column 1, and an integral oil seal 6 is provided on the end face and the journal of the steering column 1, and the integral oil seal 6 is connected from the steering column The end surface of 1 is inserted into the journal of steering column 1, wherein a convex ring 7 is provided on the inner wall of the integral oil seal 6, and the convex ring 7 is used in conjunction with the fixing groove 4.

[0014] The assembly process of this design structure is as follows: firstly put the integral oil seal 6 on the journal of the steering column 1, and then through the fixing groove 4 on the steering column 1, tap the protruding ring 7 of the integral oil seal 6 to put it on. On the steering column 1 journal, the assembly is completed.

[0015] The present invention adopts an integral o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com