Rectifying and expanding roller for flexile fabric

A flexible fabric and open-width roller technology, which is applied in the direction of fabric elongation, fabric surface trimming, textile and papermaking, etc., can solve the problems of complex deviation rectification structure, poor deviation rectification effect, and troublesome operation, and achieves accurate position and convenient operation. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

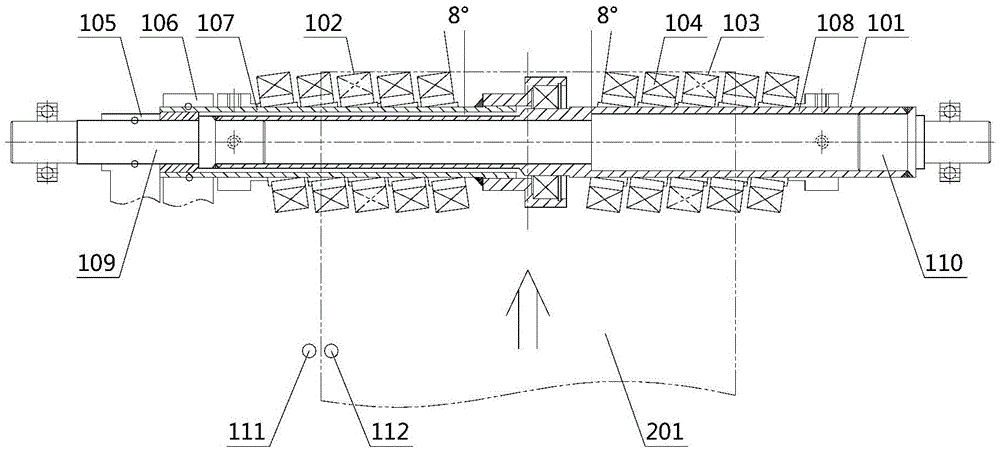

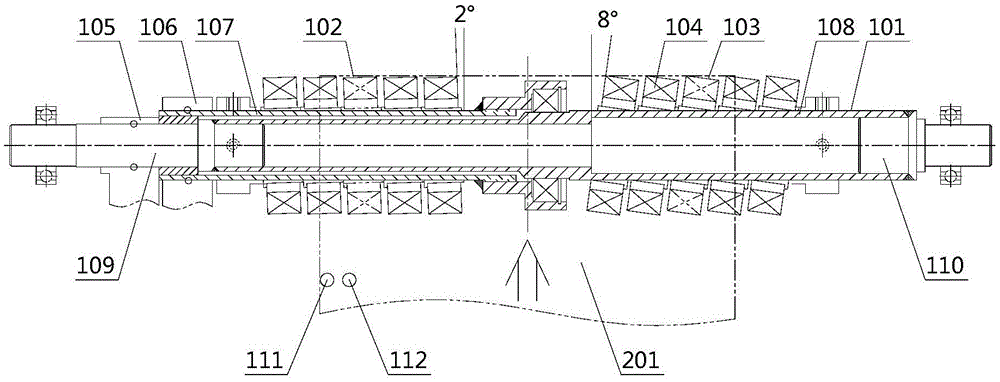

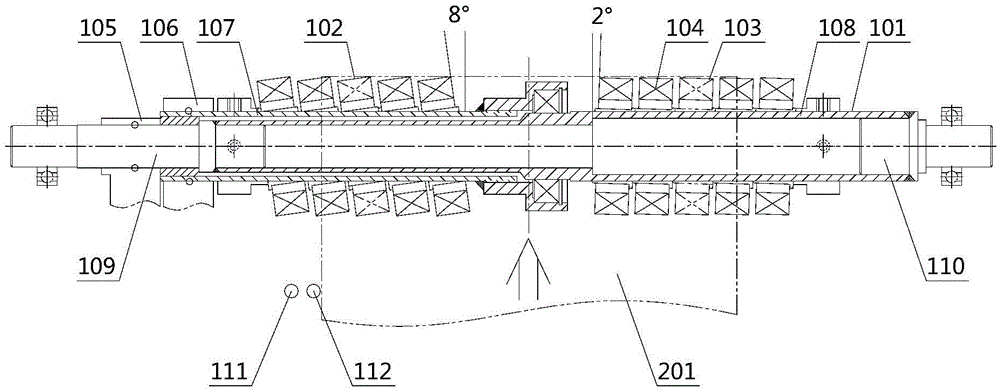

[0044] see Figure 1 ~ Figure 3 ( Figure 1 ~ Figure 3The direction of the arrow in the figure indicates the cloth feeding direction), this embodiment provides a flexible fabric deviation correcting opening roller, the flexible fabric deviation correcting opening roller includes a roller body 101, a left roller 102 and a right roller 103. The left roller 102 and the right roller 103 are oppositely connected to the roller body 101 , and the left roller 102 and the right roller 103 are arranged obliquely. The left roller 102 and the right roller 103 are symmetrically distributed about the center line of the roller body 101, and the angle formed between the plane where the left roller 102 is located and the plane where the right roller 103 is located and the plane perpendicular to the roller body 101 is , that is, the left roller 102 and the right roller 103 are inclined, and the included angle is hereinafter referred to as an inclination angle, which can be any angle.

[0045]...

no. 2 example

[0064] The basic structure, principle and technical effect of the flexible fabric deviation-correcting opening roller provided in this embodiment are the same as those of the first embodiment. For a brief description, the part not mentioned in this embodiment can refer to the first embodiment corresponding content.

[0065] The difference between the flexible fabric deviation-correcting open-width roller provided in this embodiment and the flexible fabric deviation-correcting open-width roller provided in the first embodiment lies in that the structure of the roller body 101 and the structure of the inclination adjustment device are different.

[0066] see Figure 6 ~ Figure 8 ( Figure 6 ~ Figure 8The direction of the arrow in the arrow indicates the cloth feeding direction), in this embodiment, the roller body 101 includes a mandrel 113, on which a plurality of first grooves 114 are arranged, and on the left roller 102 and the right roller 103, respectively The first protr...

no. 3 example

[0074] The basic structure, principle and technical effect of the flexible fabric correction opening roller provided by this embodiment are the same as those of the first embodiment. For a brief description, the parts not mentioned in this embodiment can refer to the first embodiment corresponding content.

[0075] The difference between the flexible fabric deviation-correcting opening roller provided in this embodiment and the flexible fabric deviation-correcting opening roller provided in the second embodiment lies in that the structure and number of the sliders 116 are different.

[0076] see Figure 9 , Figure 11 , Figure 12 as well as Figure 14 , the slider 116 includes a left slider 119 and a right slider 120, the left slider 119 is slidably connected with the left part of the mandrel 113, the right slider 120 is slidably connected with the right part of the mandrel 113, the left slider 119 and the right slider The block 120 is respectively provided with a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com