Industrial super-convenient superhydrophobic finish-coat paint and preparation method thereof

A super-hydrophobic, water-covering technology, applied in the coating and other directions, can solve the problems of harsh reaction, lengthy time and complicated process of super-hydrophobic topcoat, and achieve the effect of being conducive to industrialization, simple operation and convenient process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of this industrialized ultra-convenient super-hydrophobic finish paint comprises the following steps:

[0034] ① Preparation of transparent precursor solution: Add ethanol, water and hexadecyltrimethoxysilane to tetraethyl orthosilicate successively while stirring at a speed of 250rpm, and stir in a water bath at 70°C for 8 hours at a speed of 350rpm to obtain a transparent precursor The solution is ready for use;

[0035] ②Preparation of particle compound liquid: mix nano-colloidal silicon aqueous dispersion R301 and nano-colloidal silicon aqueous dispersion R1050 at a weight ratio of 7:3, and disperse at a speed of 350 rpm for 30 minutes to obtain particle compound liquid;

[0036] ③Mixing of transparent precursor solution and particle compound solution: add transparent precursor solution to the particle compound solution and disperse for 30 minutes, wherein the weight ratio of transparent precursor solution to particle compound solution is 4:1,...

Embodiment 2

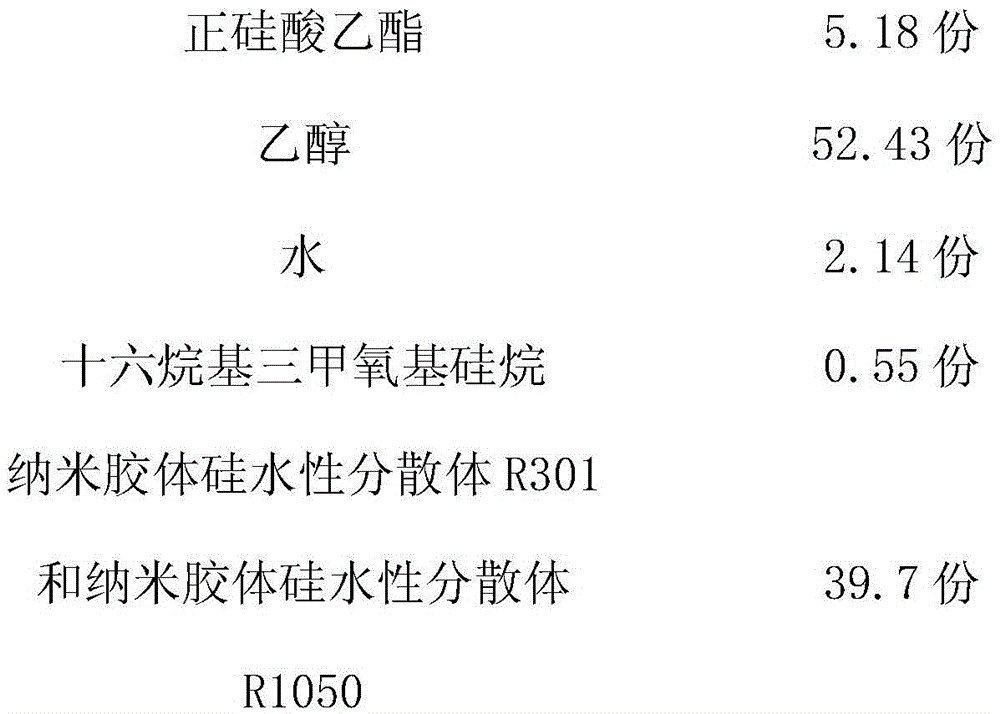

[0038] A super-convenient and super-hydrophobic finish paint that can be industrialized, it includes: it is formulated by the following components by weight,

[0039]

[0040] The preparation method of this industrialized ultra-convenient super-hydrophobic finish paint comprises the following steps:

[0041] ① Preparation of transparent precursor solution: Add ethanol, water and hexadecyltrimethoxysilane to tetraethyl orthosilicate sequentially while stirring at a speed of 200 rpm, stir in a water bath at 70°C for 8 hours at a medium speed of 400 rpm, and obtain The transparent precursor solution is ready for use;

[0042] ②Preparation of particle compound liquid: Mix nano-colloidal silicon aqueous dispersion R301 and nano-colloidal silicon aqueous dispersion R1050 at a weight ratio of 7:3, and disperse at a speed of 300 rpm for 30 minutes to obtain particle compound liquid;

[0043] ③Mixing of transparent precursor solution and particle compound solution: add transparent ...

Embodiment 3

[0045] A super-convenient super-hydrophobic finish paint that can be industrialized, comprising:

[0046]

[0047] The preparation method of this industrialized ultra-convenient super-hydrophobic finish paint comprises the following steps:

[0048] ① Preparation of transparent precursor solution: Add ethanol, water and hexadecyltrimethoxysilane to tetraethyl orthosilicate sequentially while stirring at a speed of 300 rpm, and stir in a water bath at 70°C for 8 hours at a speed of 300 rpm to obtain a transparent precursor The solution is ready for use;

[0049] ②Preparation of particle compound liquid: mix nano-colloidal silicon aqueous dispersion R301 and nano-colloidal silicon aqueous dispersion R1050 at a weight ratio of 1:1, and disperse at a speed of 400 rpm for 30 minutes to obtain particle compound liquid;

[0050] ③Mixing of transparent precursor solution and particle compound solution: add transparent precursor solution to the particle compound solution and dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com