Fast preparation of nano environmental protection chemical coating liquid and using method thereof

A nano and rapid technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of unsatisfactory long-term construction, reduction of isocyanate content, complex mixing process, etc., and achieve significant economic benefits and excellent anti-corrosion effects. The preparation process is simple and quick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1. Rapid preparation of nano-environmental protection chemical coating solution and its application method

[0026] The rapid preparation of nano-environmental protection chemical coating solution and its use method of this example include: (1). Rapid preparation of nano-environmental protection solvent-based chemical coating liquid and its use method; (two). Rapid preparation of nano-environmental protection water-soluble chemical coating Plating baths and methods of use.

[0027] (1). Quickly prepared nano-environmentally friendly solvent-based chemical coating solution and its application method

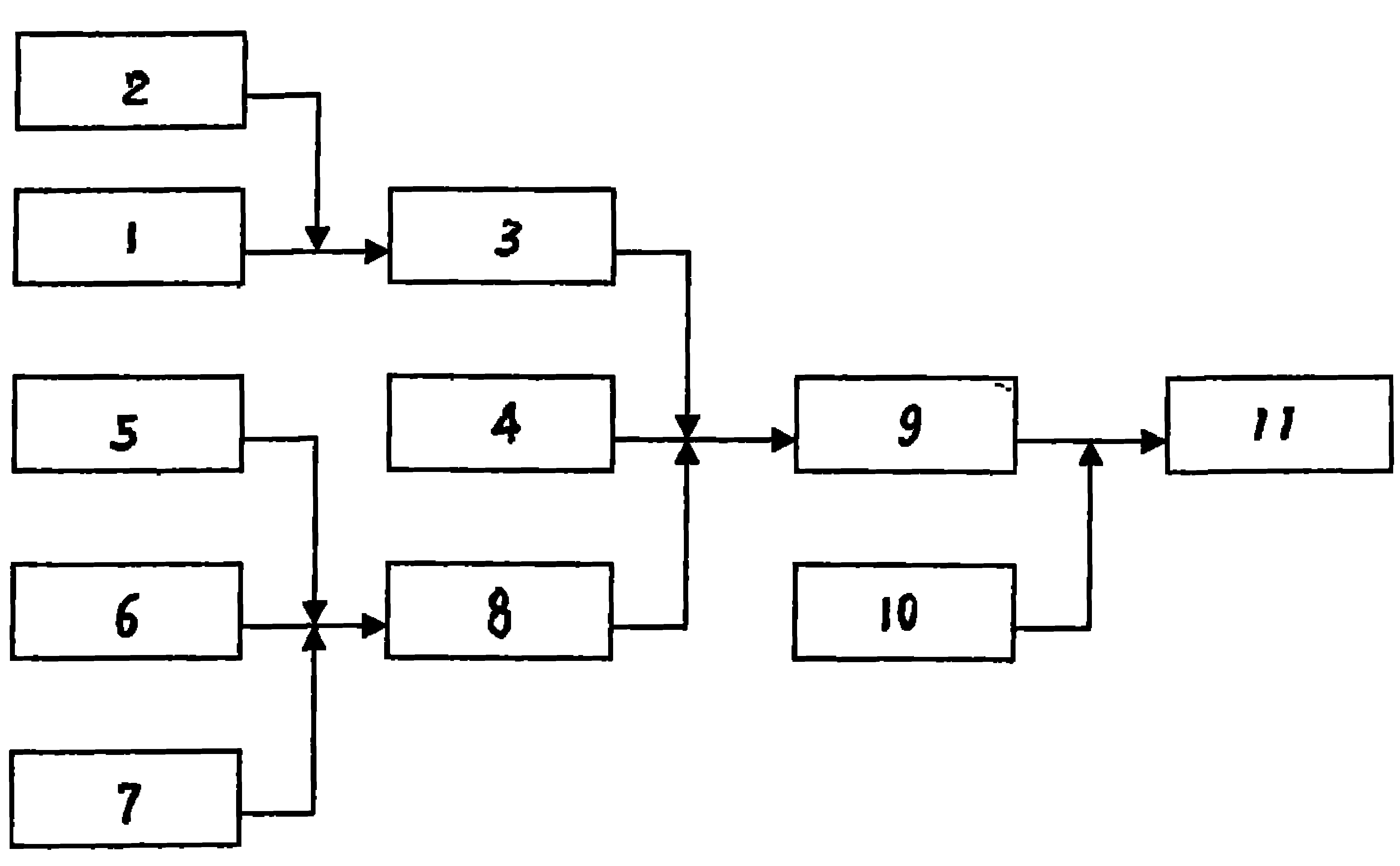

[0028] 1). The rapid preparation of nano-environmental protection solvent-based chemical coating solution of this example is prepared by a simple and rapid method according to its component ratio. 1-11 of Figure 1 shows the rapid preparation of nano-environmental protection solvent-based chemical coating solution of this example. Process flow of coating solution...

Embodiment 2

[0041] Embodiment 2. Rapid preparation of nano-environmental protection chemical coating solution and its application method

[0042] (1) Quickly prepared nano-environmental protection solvent-based chemical coating solution and its application method

[0043] 1). The rapid preparation of nano-environmental protection solvent-based chemical coating solution of this example is prepared by a simple and rapid method according to its component ratio:

[0044] i. The basic plating solution of the rapid preparation of nano-environmental protection solvent-based chemical coating solution of this example and the (one) 1) of embodiment one. The difference has: (i). Its formulation components and formulation weight ratio As follows: curing agent: main agent: functional auxiliary agent == 200 parts: 150 parts: 50 parts, the above three raw materials are mixed according to the formula ratio, and the finished product is prepared by stirring and dispersing evenly; (ii). Epoxy resin solutio...

Embodiment 3

[0056] Embodiment three. Quickly prepare nano-environmental protection chemical coating solution and its application method

[0057] (1). Quickly prepared nano-environmentally friendly solvent-based chemical coating solution and its application method

[0058] 1). The rapid preparation of nano-environmental protection solvent-based chemical coating solution of this example is prepared by a simple and rapid method according to its component ratio:

[0059] i. the basic plating solution of the rapid preparation nano-environmental protection solvent-type chemical coating solution of this example and embodiment one (one) 1). In, embodiment two (one) 1). The different points described in have: ( i). Its formula components and its formula weight ratio are as follows: curing agent: main agent: functional auxiliary agent == 120 parts: 110 parts: 35 parts; (ii). The main agent adopts epoxy resin solution, which Components and formula weight ratio are as follows: epoxy resin: solvent=2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com