Implant

A technology of implants and connection plugs, which is applied in the field of implants, can solve the problems of fixing screws for a long time and time-consuming, and achieve the effects of simple and fast manufacturing and disconnection, low processing cost of grooves, and reduced use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

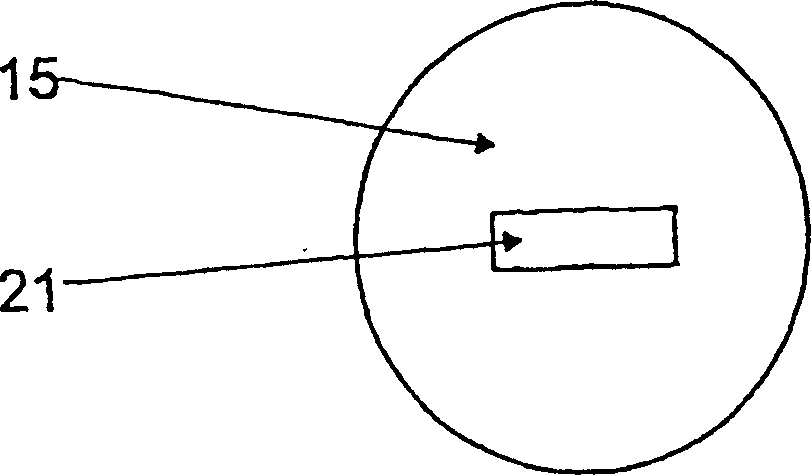

[0028] Figure 1 to Figure 5 It is an implant 1 made of titanium, which has an approximately conical shape with external threads 2 on its outer surface. The implant 1 also has a rounded distal end 3 and a proximal end 4, and the proximal end is composed of a true circular upper top surface 5. In a section 6 adjacent to the upper top surface 5, the implant 1 has a cylindrical shape with an outer surface 7 that is highly polished. In the following threaded section 8, the implant 1 is made tapered. Starting from the upper top surface 5, a receiving eyelet 10 extends along the longitudinal axis 9 parallel to the implant 1 and passes through the total length of the segment 6 and a part of the length of the threaded segment 8.

[0029] Such as image 3 As shown, the cross-section of the receiving eye 10 in the range of the segment 6 is all a rounded rectangular shape. Starting from the threaded section 8, the cross section of the receiving eyelet 10 gradually becomes smaller downwards. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com