A kind of packaging production equipment

A production equipment and control device technology, which is applied in the field of production equipment, can solve the problems of large equipment footprint, unfavorable human health, and low production efficiency, and achieve the effects of small equipment footprint, saving transportation procedures, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

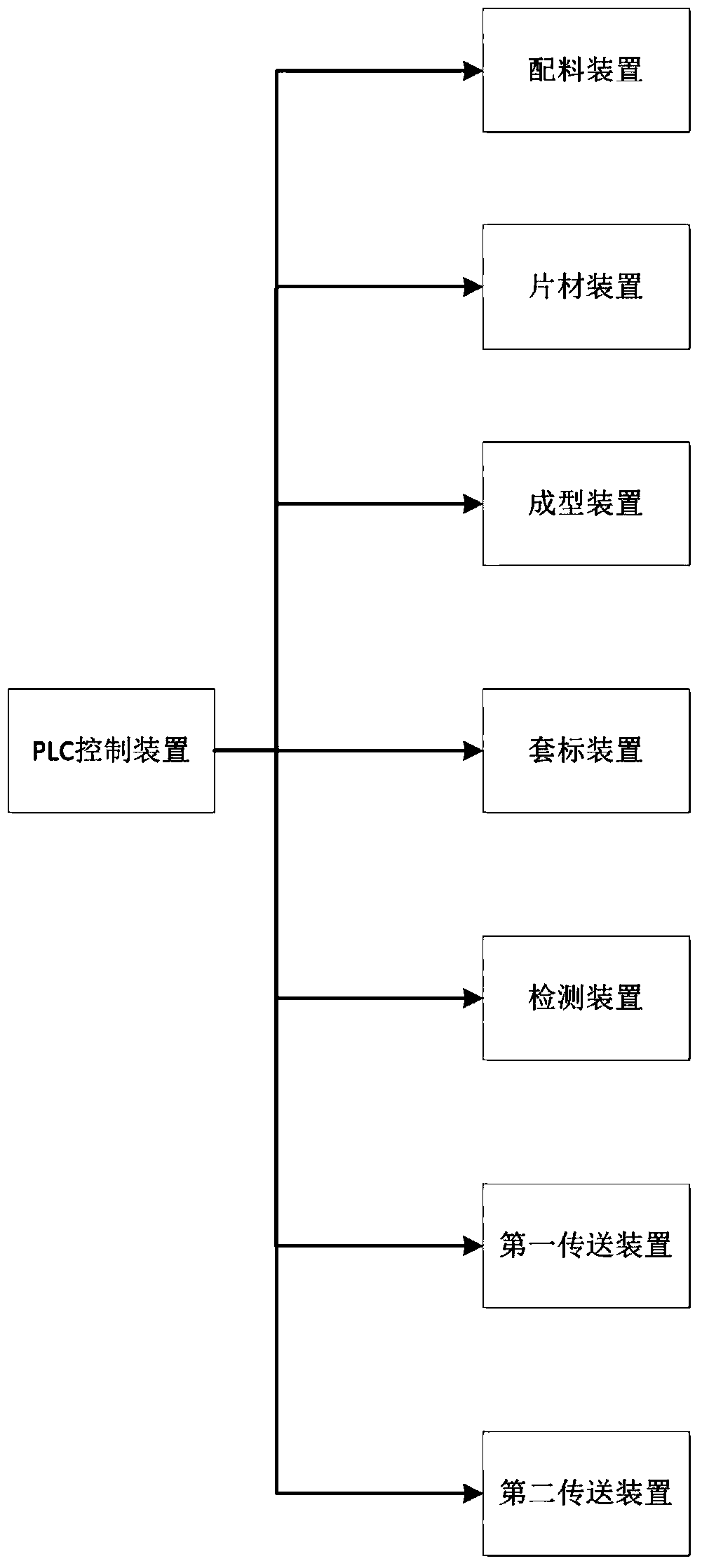

[0010] Example as figure 1 and figure 2 As shown, the packaging equipment includes a frame, a batching device 1, a sheet device 2, a forming device 3, a sleeve label device 4, a detection device 5, a PLC control device, a first conveying device and a second conveying device; the PLC The control device is respectively connected with the batching device 1, the sheet material device 2, the forming device 3, the sleeve label device 4, the detection device 5, the first conveying device and the second conveying device The batching device 1 includes at least one storage bin, a batching bucket and a driving device, and the batching bucket includes a stirring device; the PLC control device controls the closing of the outlet of the storage bin according to the preset batching ratio Batching ratio; the PLC control device controls the driving device to control the stirring speed of the stirring device; the outlet of the batching device 1 is provided with a spectral analysis detection de...

Embodiment 2

[0012] Embodiment 2, the packaging equipment includes a frame, a batching device 1, a sheet device 2, a forming device 3, a sleeve label device 4, a detection device 5, a PLC control device, a first conveying device and a second conveying device; The PLC control device is respectively connected with the batching device 1, the sheet material device 2, the forming device 3, the sleeve label device 4, the detection device 5, the first conveying device and the second conveying device Connected; the batching device 1 includes at least one storage bin, a batching bucket and a drive device, and the batching bucket includes a stirring device; the PLC control device controls the closing of the outlet of the storage bin according to the preset batching ratio Control the batching ratio; the PLC control device controls the driving device to control the stirring speed of the stirring device; the outlet of the batching device 1 is provided with a spectral analysis detection device, which det...

Embodiment 3

[0015] Embodiment 3, the packaging equipment includes a frame, a batching device 1, a sheet device 2, a forming device 3, a sleeve label device 4, a detection device 5, a PLC control device, a first transmission device and a second transmission device; The PLC control device is respectively connected with the batching device 1, the sheet material device 2, the forming device 3, the sleeve label device 4, the detection device 5, the first conveying device and the second conveying device Connected; the batching device 1 includes at least one storage bin, a batching bucket and a drive device, and the batching bucket includes a stirring device; the PLC control device controls the closing of the outlet of the storage bin according to the preset batching ratio Control the batching ratio; the PLC control device controls the driving device to control the stirring speed of the stirring device; the outlet of the batching device 1 is provided with a spectral analysis detection device, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com