Fast drying full quantitative coating equipment

A rapid drying and coating technology, applied in the direction of coating, liquid coating device on the surface, liquid spraying device, etc., can solve the problems affecting production efficiency, lack of fully automatic coating equipment, etc., and reach the applicable industrial field Extensive, high degree of automation, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

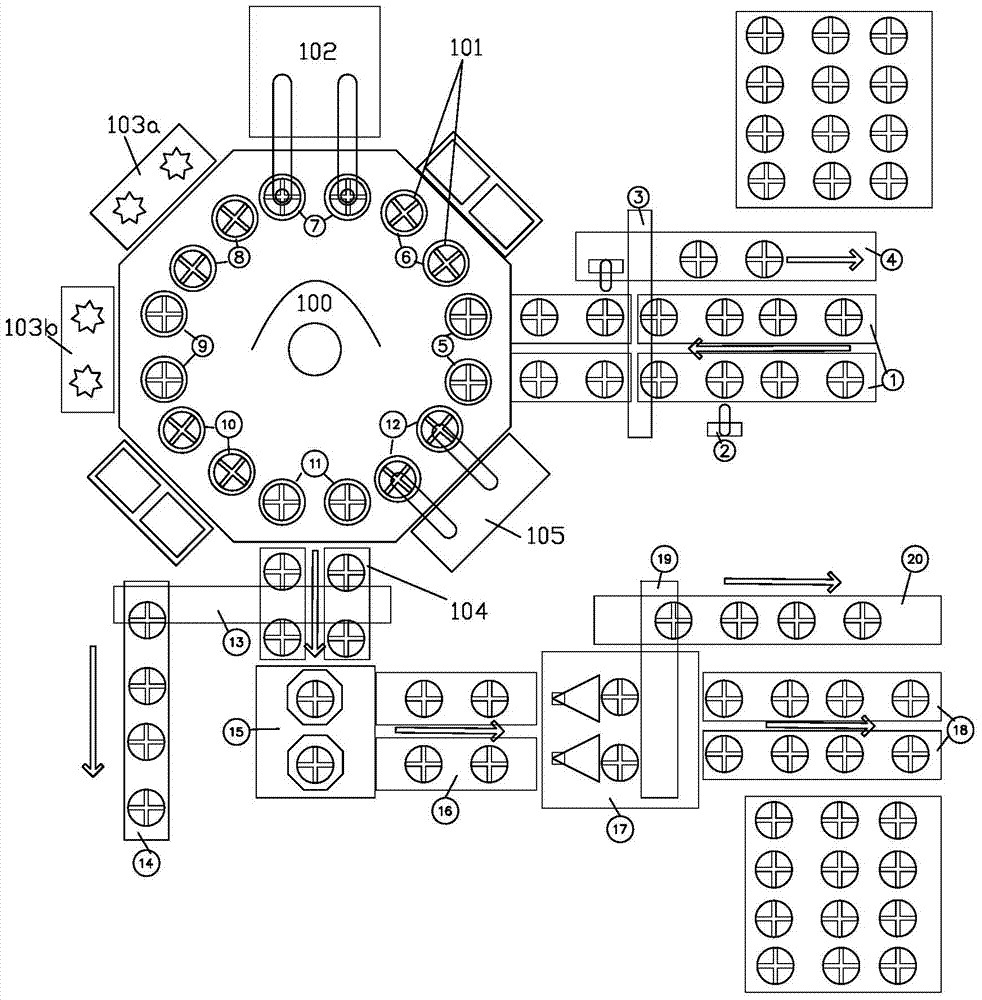

[0026] The fast drying full quantitative coating equipment proposed by the present invention, such as figure 1 As shown, it includes a central turntable 100, a feeding conveyor belt 1, a code spraying and code reading device 2, an error code elimination device 3, an error code elimination transmission line 4, a first station 5, a second station 6, and a third station 7. The fourth station 8, the fifth station 9, the sixth station 10, the seventh station 11, the eighth station 12, the wet weight gain unqualified product rejecting device 13, the coating unqualified product rejecting line 14 , drying station 15, plugging detection transmission line 16, plugging detection equipment 17, blanking transmission line 18, plugging detection unqualified rejecting device 19, plugging detection unqualified product rejection line 20;

[0027] In the counterclockwise directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com