Method for producing porous cellulose particles, and porous cellulose particles

A manufacturing method and technology of cellulose, applied in the direction of cation exchange materials, chromatographic cation exchangers, organic cation exchangers, etc., can solve the problems of cost or environmental load, not easy to make equipment, etc., and achieve the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124]48.1 g of cellulose diacetate (Wako Pure Chemical Industries, Ltd., acetylation degree: 53% to 56%) was added to 352.5 g of 85% by weight aqueous acetic acid solution, and stirred. Furthermore, it heated up and stirred at 60 degreeC for 1 hour, thereby dissolving the cellulose diacetate, and obtaining the transparent solution whose diacetate cellulose density|concentration was 12 weight%. The solution was quickly injected into 1.5 L of o-dichlorobenzene at 100° C. containing 1.97 g of surfactant sorbitan monooleate, and stirred at 400 rpm for 10 minutes to obtain a dispersion system. Then, the dispersion system was cooled, and when it reached 30° C., 620 mL of pure water as a poor solvent was added dropwise. As a result, cellulose diacetate was precipitated to obtain spherical cellulose diacetate particles. Thereafter, the resulting cellulose diacetate particles were sufficiently washed with a large amount of methanol and then water. Next, the washed spherical cellulos...

Embodiment 2 and Embodiment 3

[0159] Porous cellulose particles were produced in the same manner as in Example 1, except that the concentration of cellulose diacetate in the cellulose diacetate solution was 10% by weight (Example 2) and 4% by weight (Example 3). The particle size distribution and Kav value of the obtained porous cellulose particles were measured in the same manner as in Example 1.

[0160] The results of Examples 1 to 3 are shown in Table 1 below. The Kav values shown in Table 1 are values in the case of PEG4120 (POLYMER LABORATORIES).

[0161] [Table 1]

[0162]

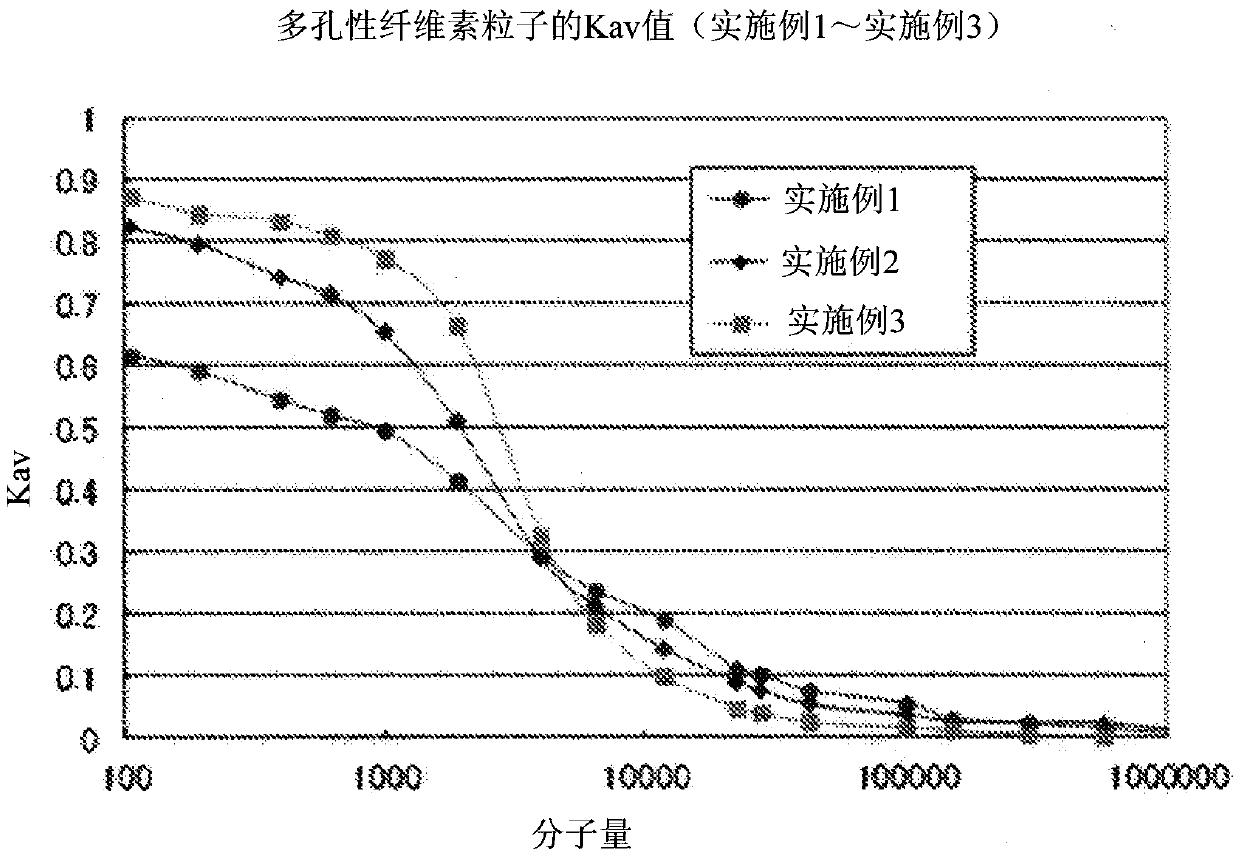

[0163] From Table 1, it can be said that the higher the concentration of cellulose diacetate, the larger the average particle diameter of the obtained porous cellulose particles tends to be. exist figure 1 The Kav values of the porous cellulose particles obtained in Examples 1 to 3 are shown in . according to figure 1 It can be said that the higher the concentration of cellulose diacetate, the smaller the Kav value...

Embodiment 4

[0165] Porous cellulose particles were produced in the same manner as in Example 1, except that the concentration of cellulose diacetate in the cellulose diacetate solution was 10% by weight, and 620 mL of 50% methanol aqueous solution was used as a poor solvent. The particle size distribution and Kav value of the obtained porous cellulose particles were measured in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of acetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com