Technological method for encapsulating micro-rectangular jack electric connector

An electrical connector and process method technology, applied in the field of micro-rectangular jack electrical connector potting process, can solve the problems of complex process, dielectric withstand voltage and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

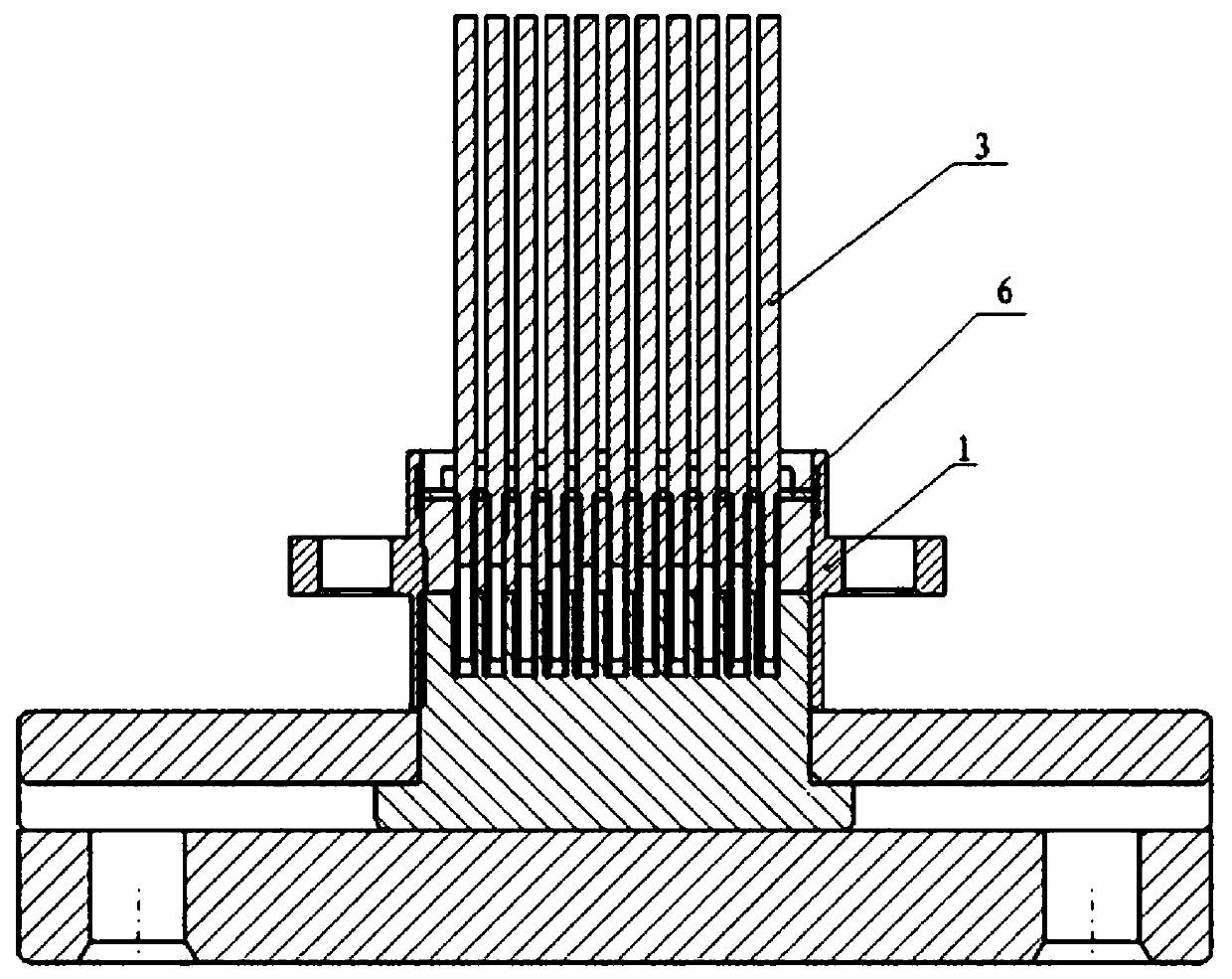

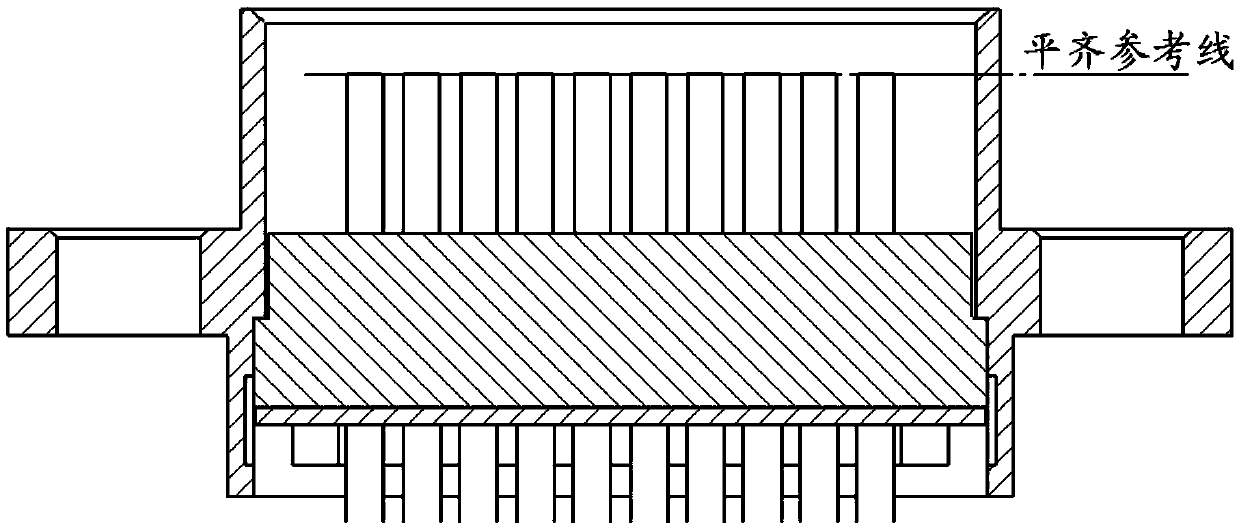

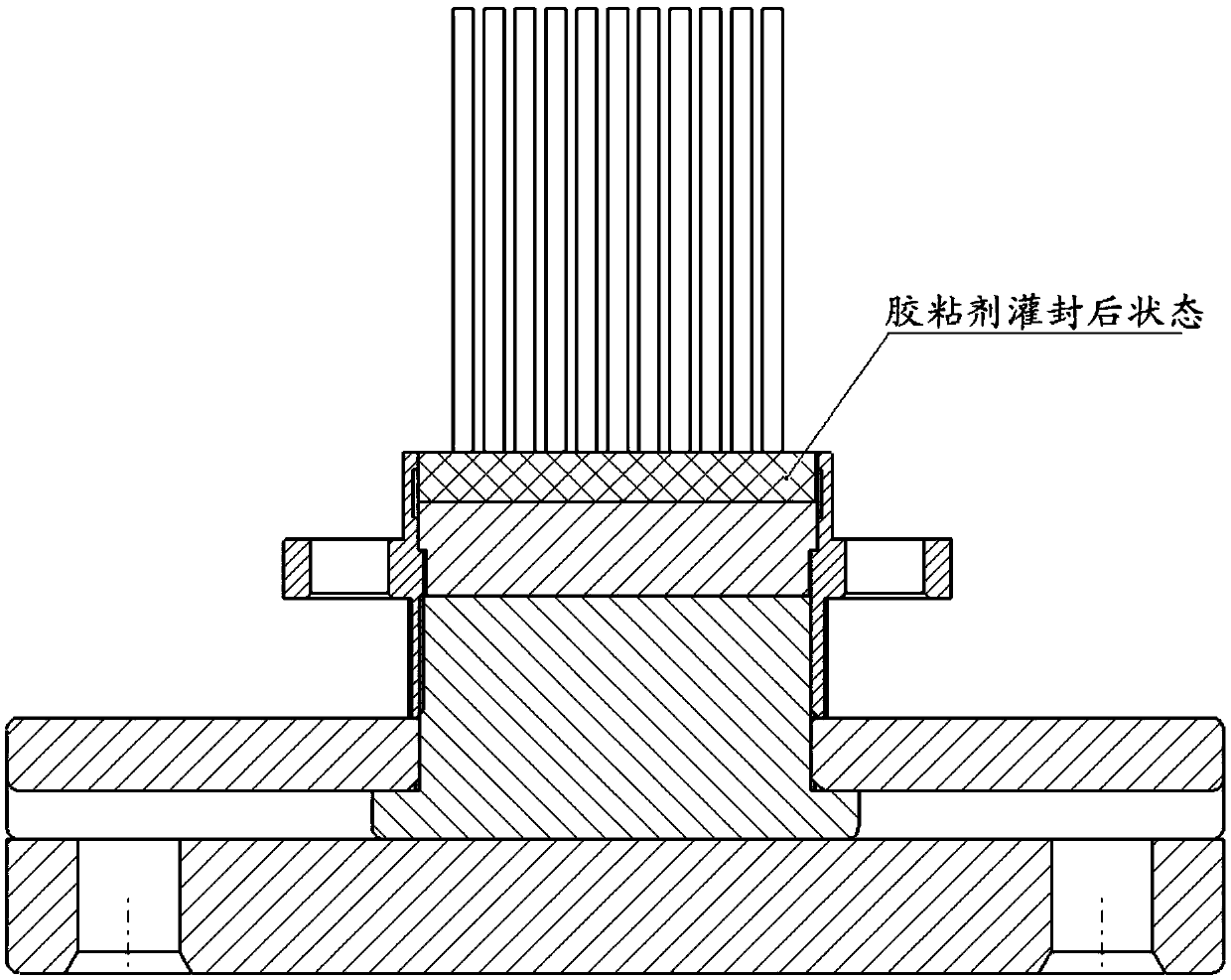

[0036] The steps of the potting process method for the micro-rectangular jack electrical connector are as follows:

[0037] Prepare before potting, prepare hot air gun, electronic scale, potting fixture, loading tool, dismantling tool, height adjustment tool, calibration tool, glue adjustment stick, glue filling stick, glue adjustment box, etc.; prepare adhesive, absolute ethanol, Fine cotton yarn.

[0038] ① Preparation of adhesive: Select DG-3S adhesive A and adhesive B of China Blue Chenguang Chemical Research and Design Co., Ltd., and prepare adhesive A and adhesive B at a mass ratio of 1.5 to 2:1. Use an electronic scale to accurately weigh a small amount of adhesive for cleaning In the glue mixing box, no sundries can be mixed into the glue; Stir continuously with a glue stick for 1 to 2 minutes until the glue is mixed evenly and the color of the glue is consistent;

[0039] ②Insulator fixed potting: put the insulator into the shell until it is assembled in place, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com