Butterfly spring connector

A butterfly spring and connector technology, which is applied in the direction of clamping/spring connection, contact parts, etc., can solve the problems of complex structure of frame and butterfly spring, waste of production materials, inconvenience of removing wires or cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

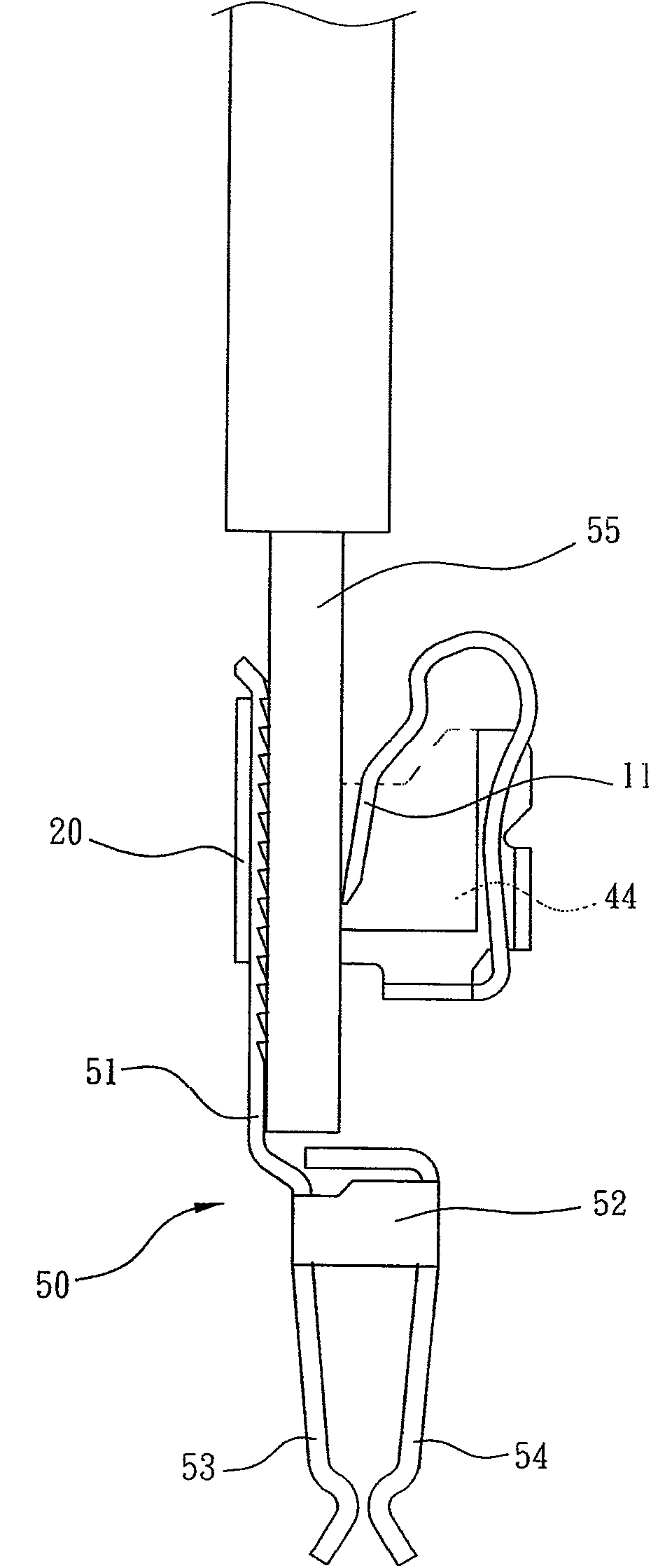

[0042] The belleville spring connector of the present invention will be described below using various embodiments. This embodiment is used to illustrate the possible structure and application of the butterfly spring connector of the present invention, and is not intended to exhaustively list all possible implementations of the present invention. The patent scope of the present invention should still be based on the claims.

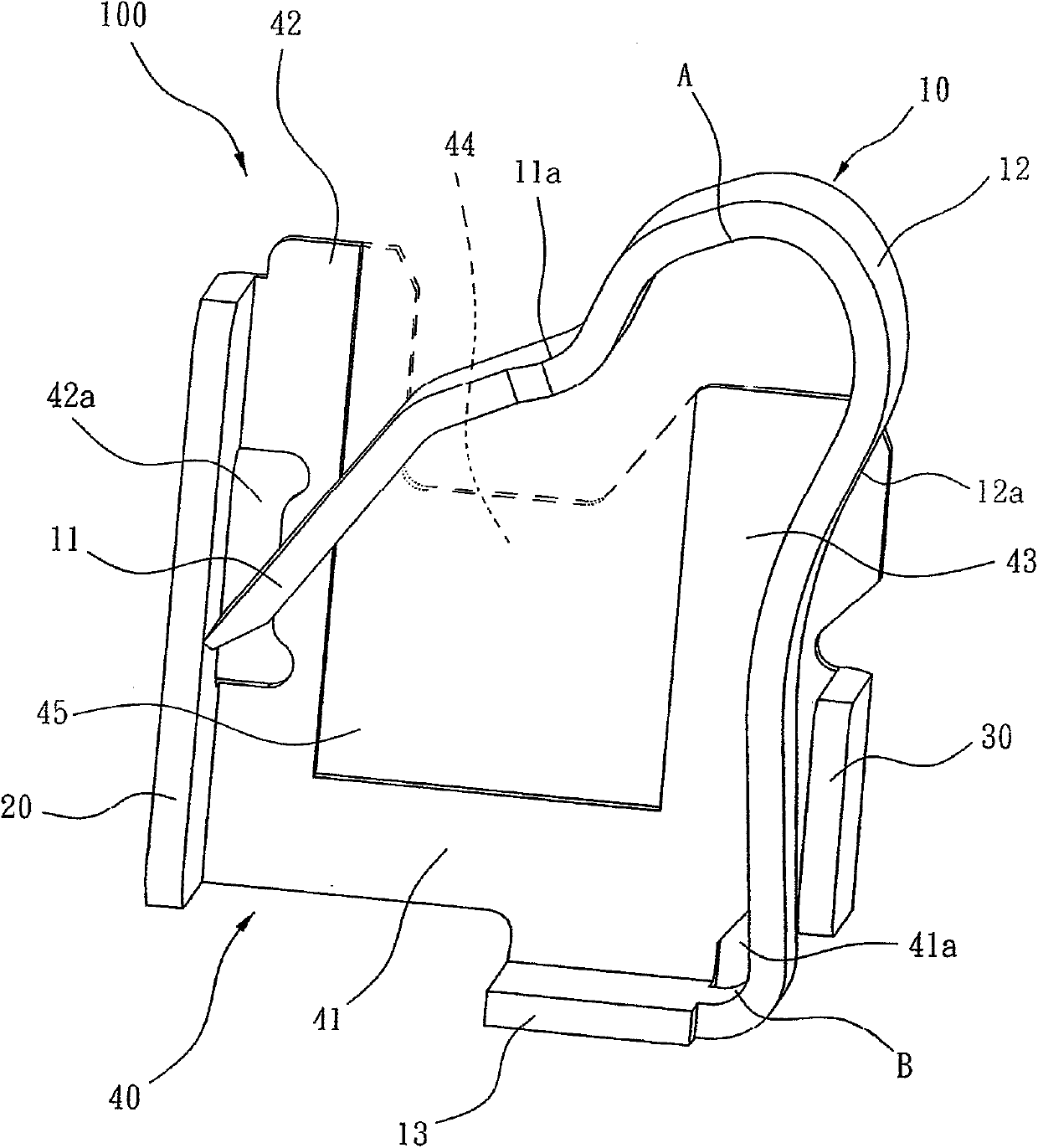

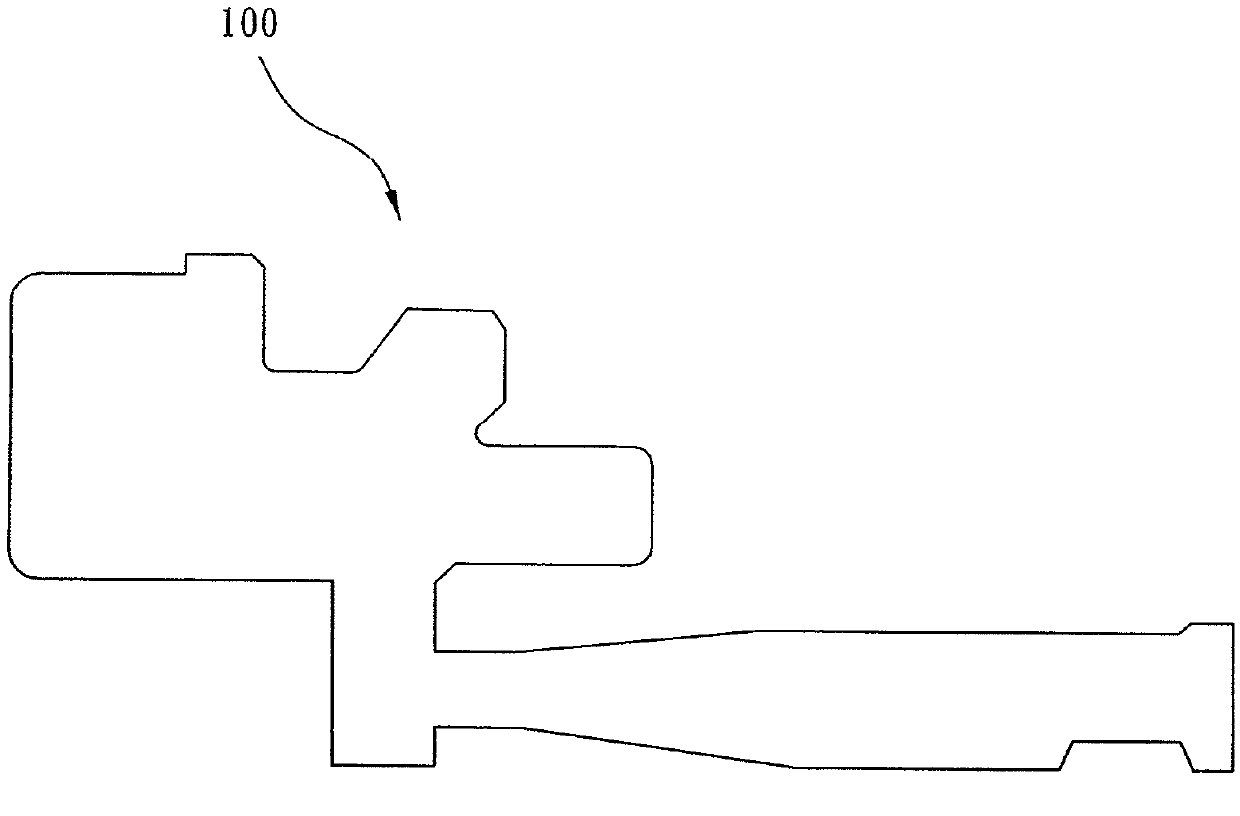

[0043] figure 1A schematic structural view showing an embodiment of the butterfly spring connector of the present invention. As shown in the figure, the butterfly spring connector 100 of the present invention is an integrally formed butterfly spring connector. In a preferred embodiment of the present invention, the belleville spring connector 100 is formed by stamping or other forming methods from a piece of conductive material, such as a metal sheet. The butterfly spring connector 100 mainly includes a butterfly spring 10 , a splint 20 and a supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com