Convenient-to-assemble automatically power battery module and electric motor car

A power battery and automatic assembly technology, applied in the field of electric vehicles, can solve the problems of difficult to realize automatic production, difficult connection of soft-pack battery core tabs and busbars, etc., to facilitate automatic assembly, solve irregular shapes, and simplify assembly procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

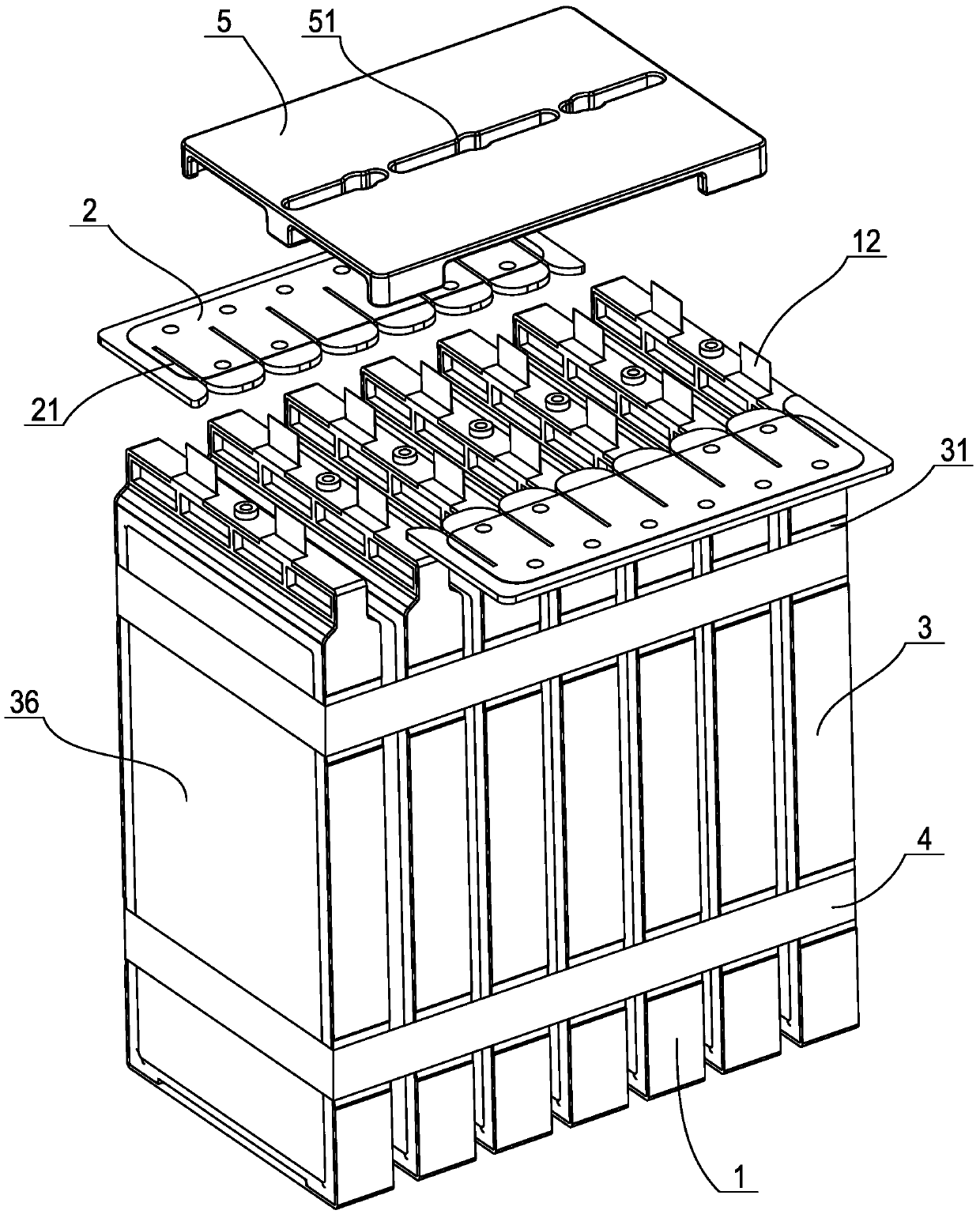

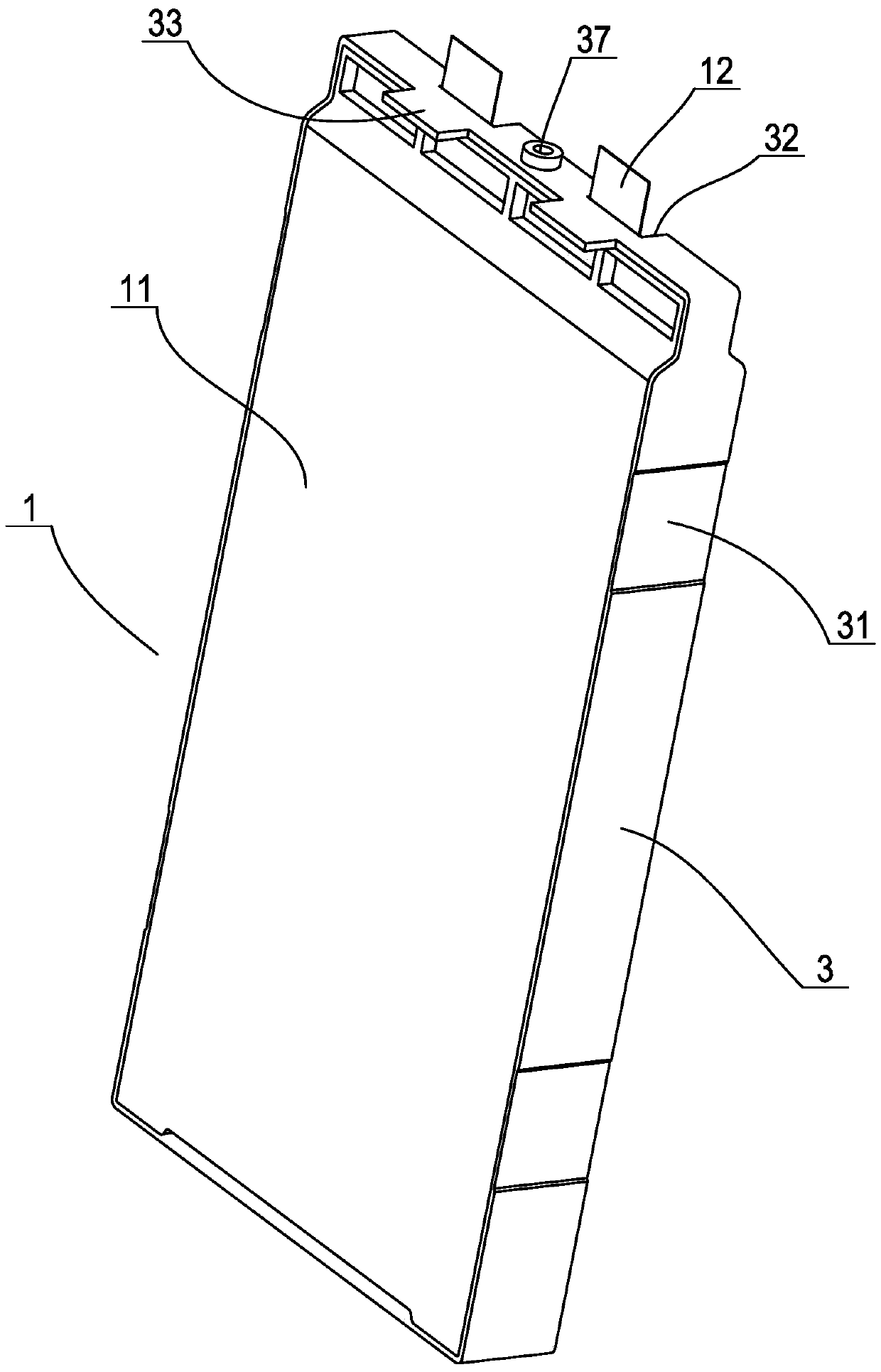

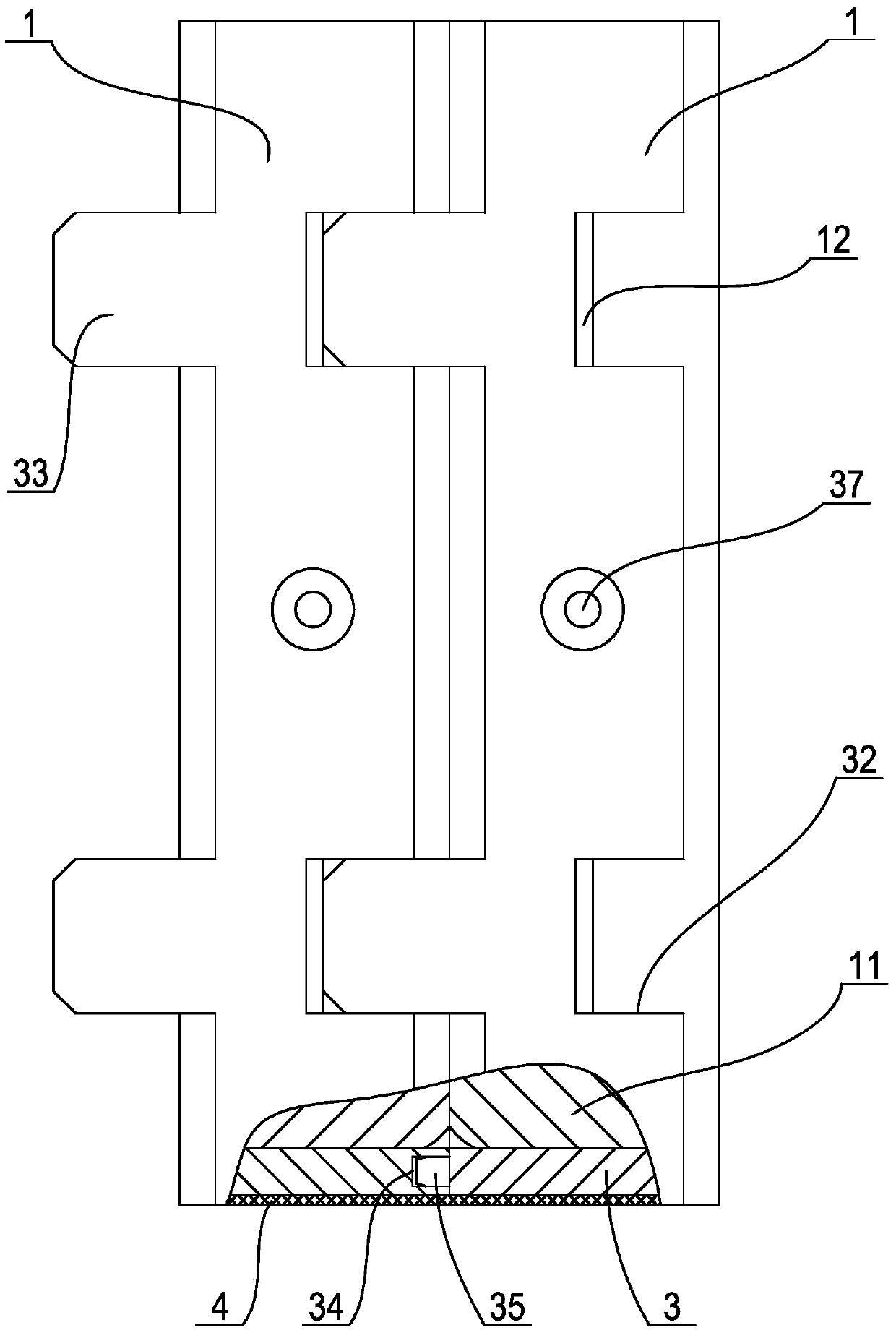

[0036] Embodiment 1: as figure 1 , figure 2 As shown, a power battery module that is convenient for automatic assembly includes several roughly rectangular soft-packed cells 11 and two bus bars 2, and each soft-packed cell is arranged side by side along its thickness direction. A tab 12 consisting of positive tabs and negative tabs arranged at intervals is provided on the side. For convenience and description, the direction in this embodiment is based on the soft-packed battery cell, where the side where the tab is set is the upper side, and the thickness direction of the soft-packed battery cell is the front and rear sides, and the left and right sides are determined accordingly. The positive tabs of each soft-packed battery cell are linearly arranged from front to back to form a positive tab string, and the positive tabs are connected through a bus bar; correspondingly, the negative tabs of each soft-packed battery cell are arranged linearly from front to back to form a ne...

Embodiment 2

[0046] Embodiment 2: An electric vehicle includes a power battery. Specifically, the power battery is composed of several power battery modules connected in series, and the power battery module adopts the power battery module described in Embodiment 1 that is convenient for automatic assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com