Spring operating mechanism for circuit breaker

A technology of operating mechanism and circuit breaker, applied in contact drive mechanism, power device inside the switch, etc., can solve the problem of unstable coordination characteristics and mechanical characteristics of the transmission system, low relative position accuracy of installation, and reduced circuit breaker reliability. and other problems, to achieve the effect of compact overall structure of the mechanism, improving energy conversion efficiency, and enhancing stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

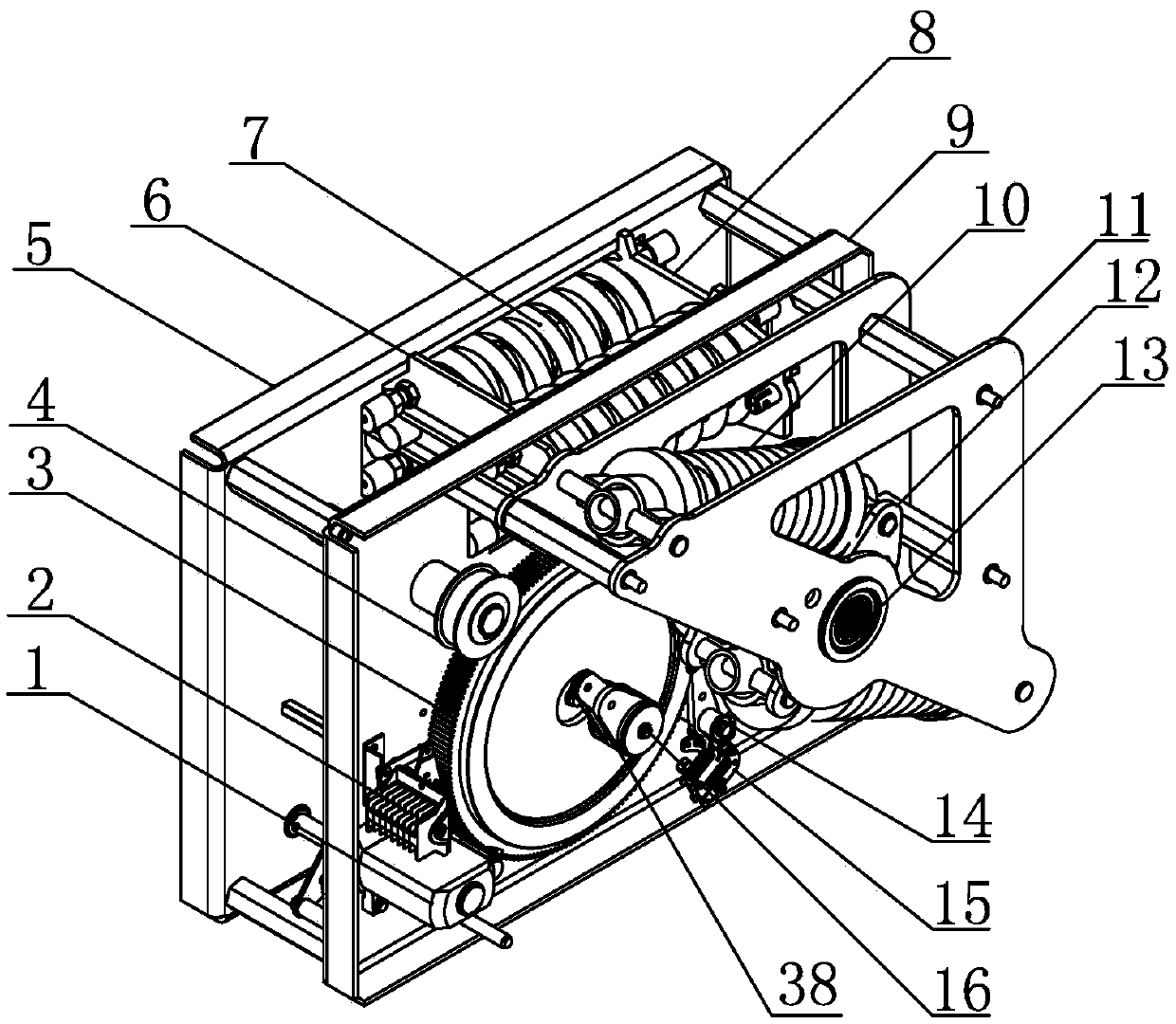

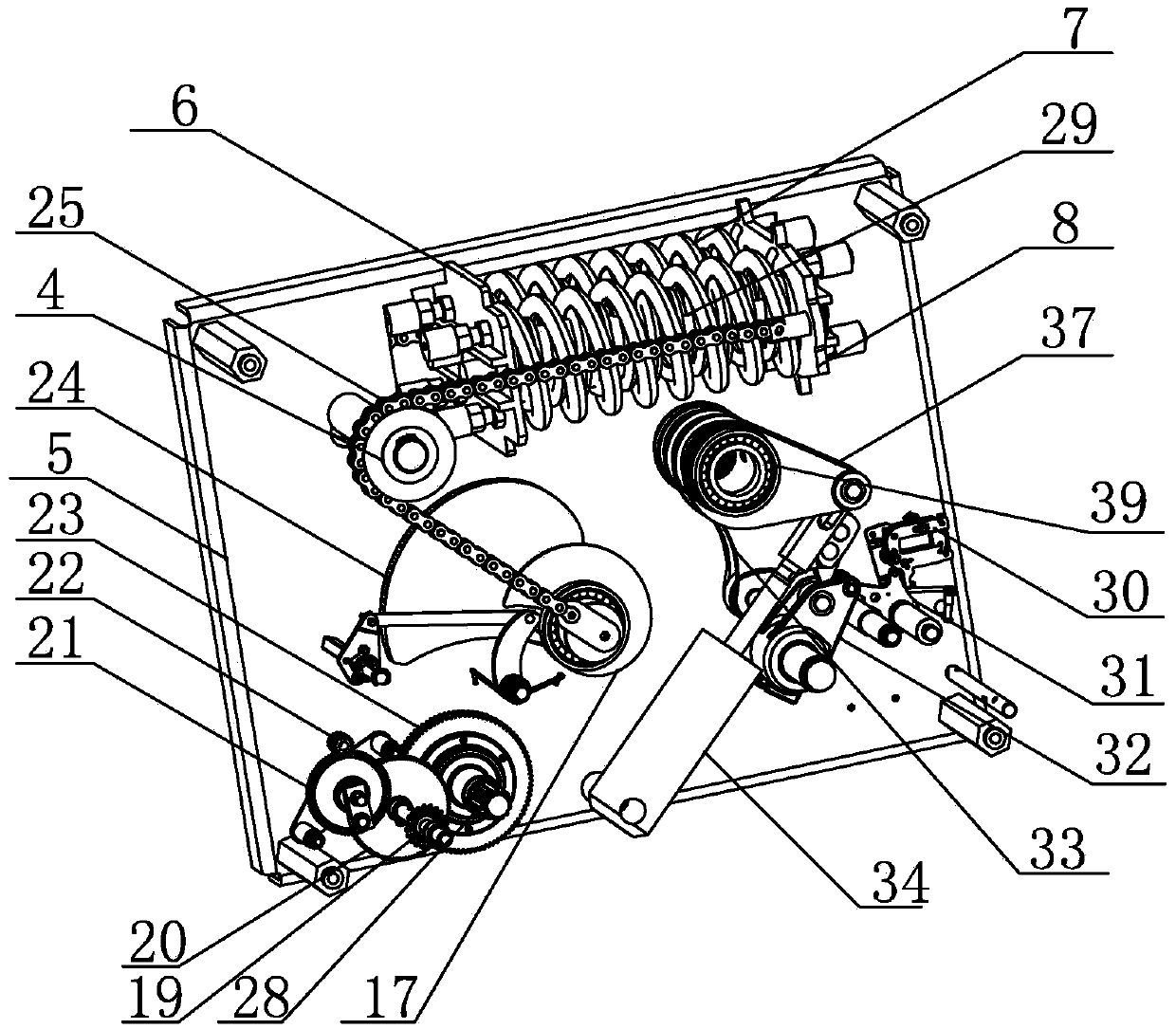

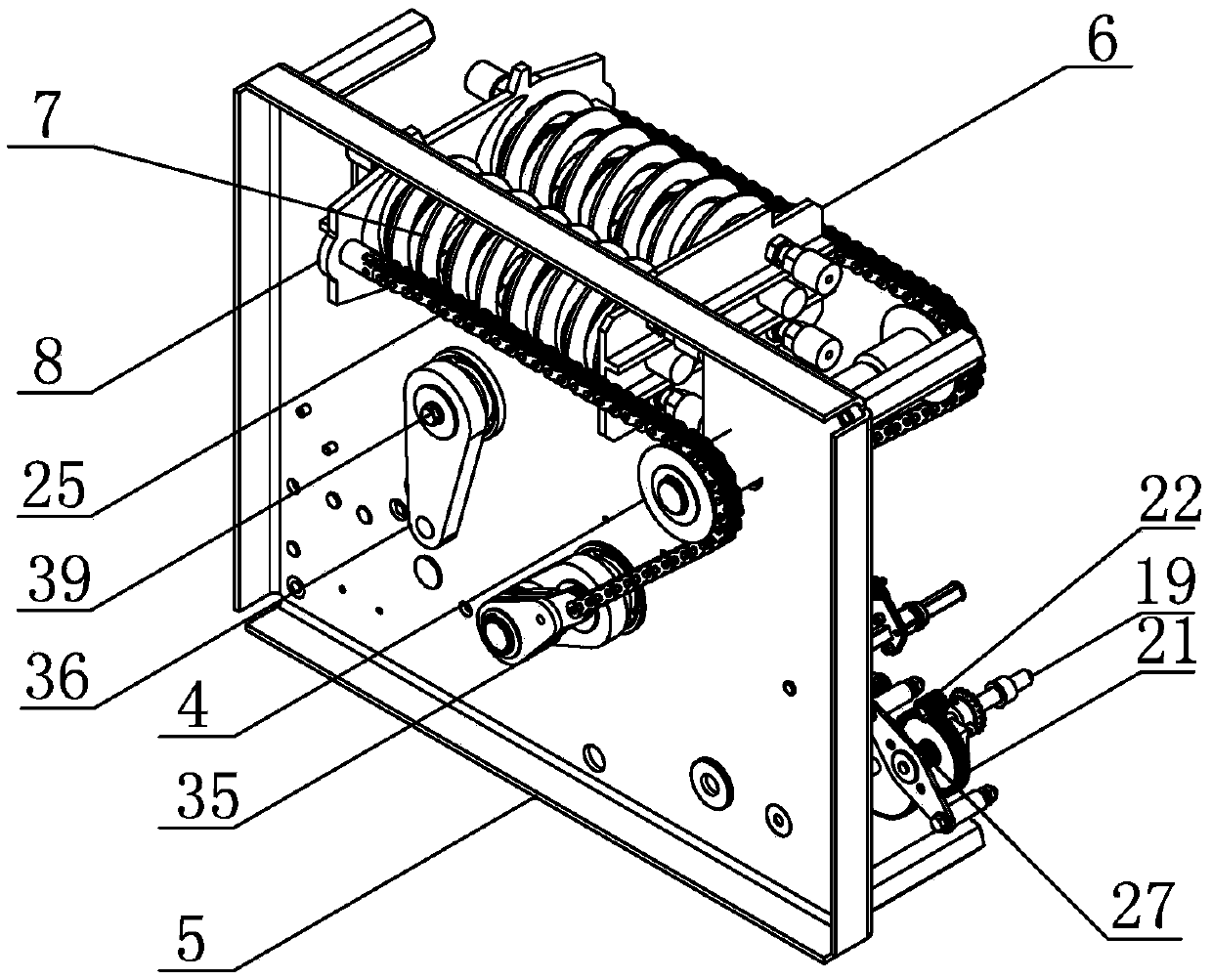

[0020] Such as Figure 1-Figure 4 As shown, the spring operating mechanism for a circuit breaker of the present invention includes two first side plates 9 and a second side plate 5 arranged side by side, the first side plate 9 and the second side plate 5 are integrated with an energy storage system, Closing and closing control systems, opening and closing control systems and auxiliary systems.

[0021] The energy storage system includes an energy storage shaft 16, the energy storage shaft 16 is installed between the first side plate 9 and the second side plate 5, and one end of the energy storage shaft 16 is equipped with a second energy storage arm 35, and the second energy storage arm 35 is installed. The arm 35 is located outside the second side plate 5, the other end of the energy storage shaft 16 is equipped with an energy storage gear 3, the energy storage gear 3 is located outside the first side plate 9, and the end face of the energy storage gear 3 is equipped with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com