Different-strip-aerial-image-based power sag detection method and system

A technology of aerial imagery and detection method, which is applied in the direction of three-dimensional position/channel control, etc., can solve the problems of measurement accuracy, cost and efficiency, slow manual detection speed, large data processing volume, etc., and achieve short data preprocessing time , low operating cost and high collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

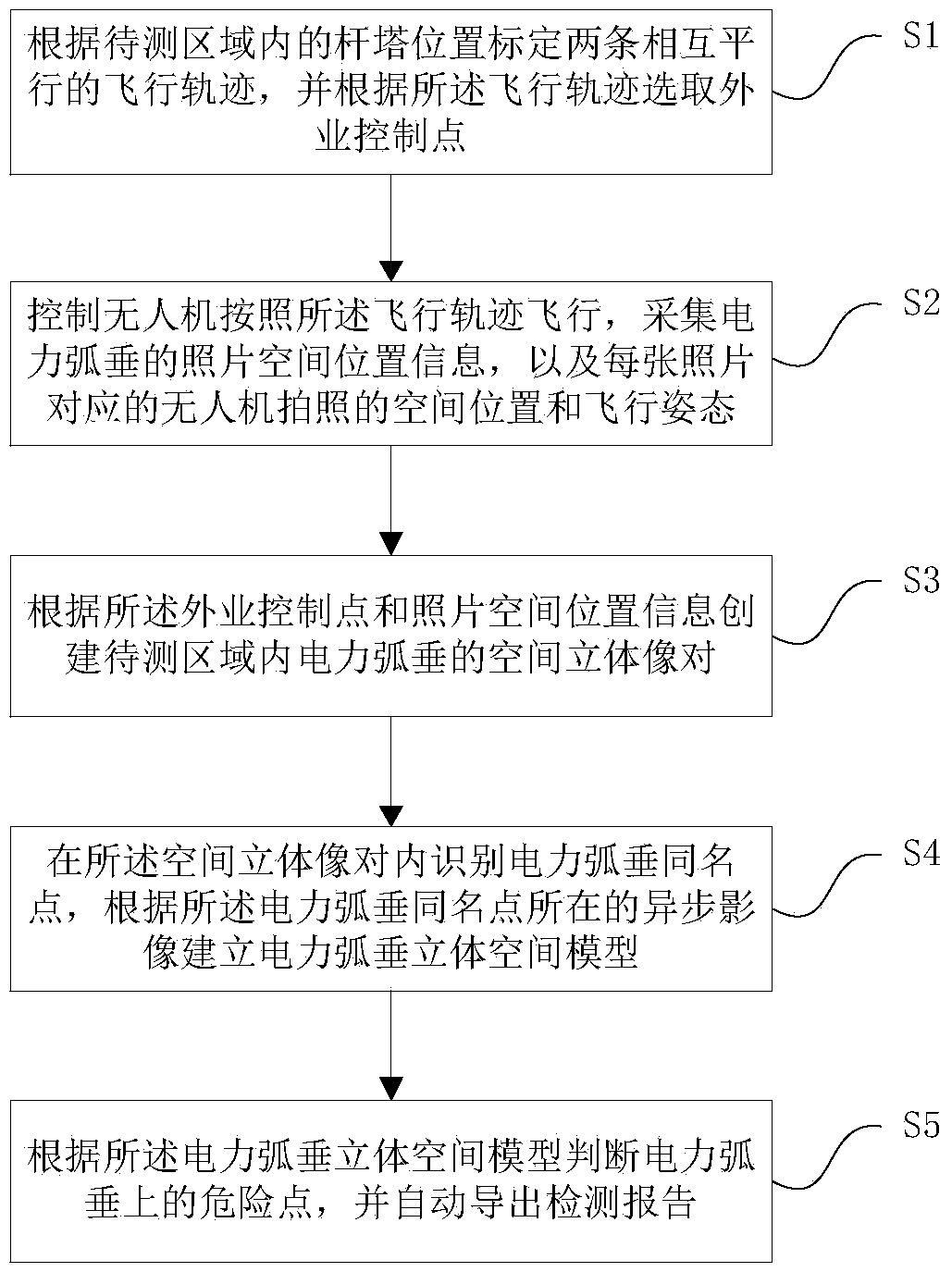

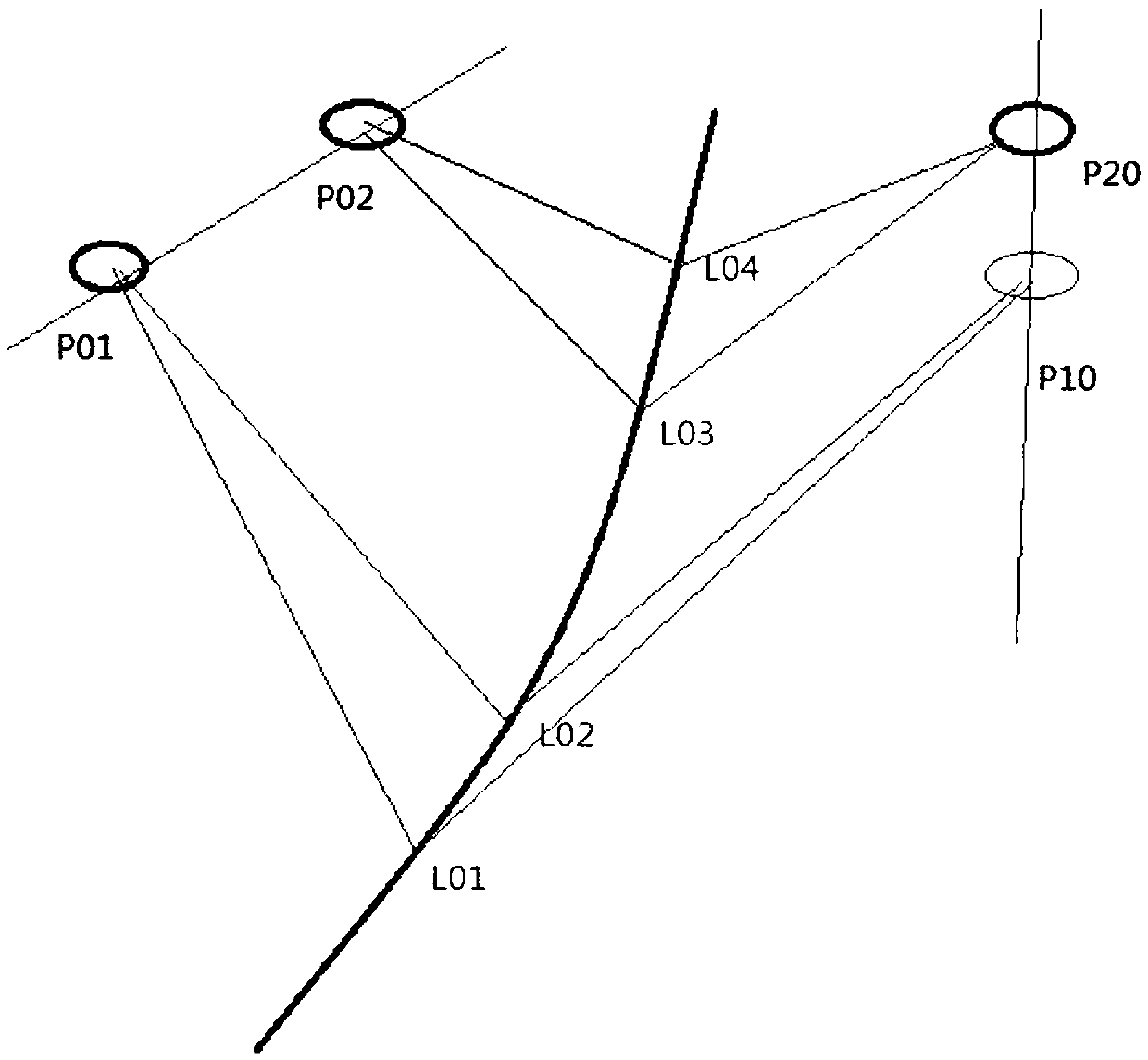

[0018] Embodiment 1, a kind of power sag detection method based on different-band aerial images, the following will be combined with the attached figure 1 A power sag detection method based on out-of-band aerial images of the present invention is described in detail.

[0019] Such as figure 1 As shown, a flow chart of a power sag detection method based on different-zone aerial images, including:

[0020] Step 1: Calibrate two mutually parallel flight trajectories according to the position of the tower in the area to be measured, and select field control points according to the flight trajectories;

[0021] Step 2: Control the UAV to fly according to the flight trajectory, and take pictures at the same time to collect the photo space position information of the power sag in the area to be measured, and the space position and flight attitude of the UAV photo corresponding to each photo;

[0022] Step 3: Create a spatial three-dimensional image pair of power sag in the area to ...

Embodiment 2

[0033] Embodiment 2, a kind of power sag detection system based on different-band aerial images, the following will be combined with the attached image 3 A power sag detection system based on out-of-band aerial images of the present invention is described in detail.

[0034] Such as image 3 As shown, a schematic diagram of the structure of a power sag detection system based on different-zone aerial images, including a calibration selection module, a main control module, a spatial stereo image pair module, a stereo space model measurement module, and a diagnosis module.

[0035]Wherein, the calibration selection module is used to receive the position of the tower in the area to be measured from the outside, calibrate two mutually parallel flight trajectories according to the position of the tower, and automatically select the field control point according to the flight trajectories; the main control module It is used to control the UAV to fly according to the flight trajecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com