Micro-motion device module

A micro-motion device and lens technology, applied in installation, optics, instruments, etc., can solve problems such as low production efficiency, high difficulty, complex assembly of optical and mechanical parts, etc., to reduce investment, avoid appearance, improve production efficiency and excellent rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

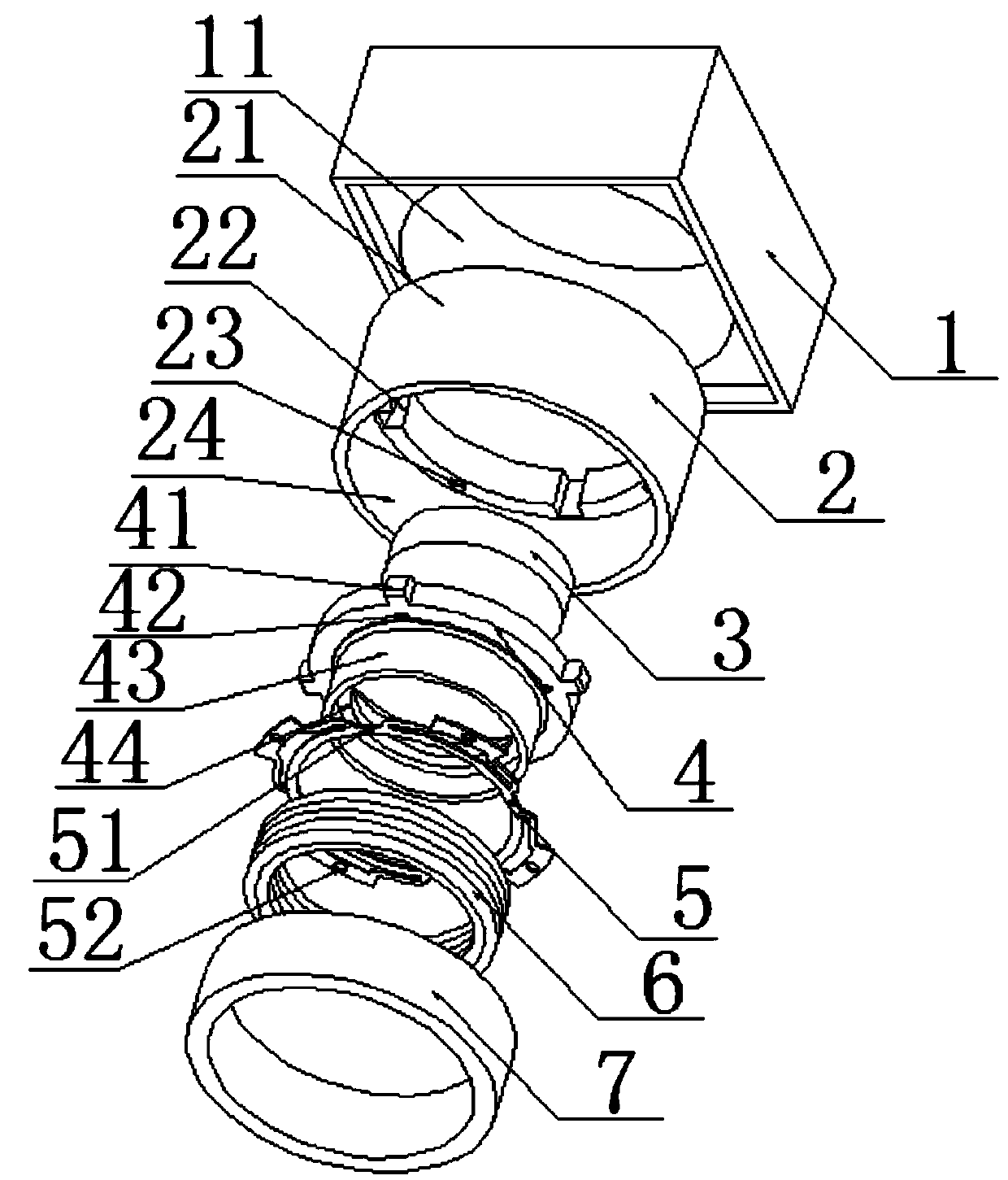

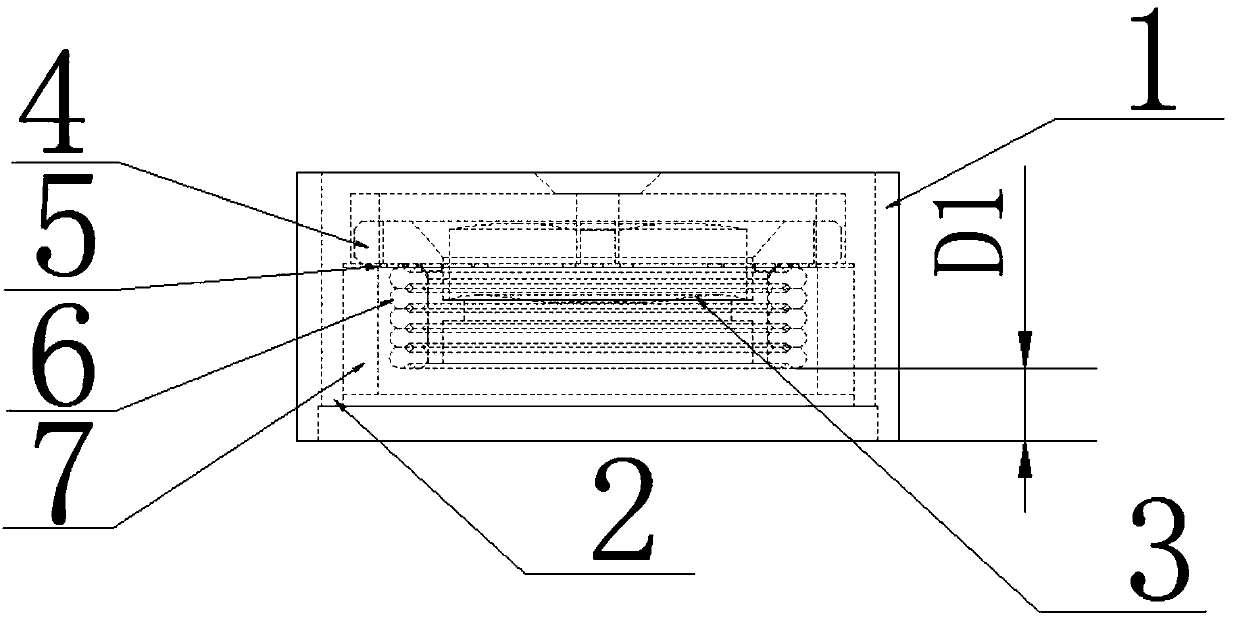

[0022] Combine figure 1 Shown is a three-dimensional exploded schematic diagram of one of the structures used to realize the micro-motion device of the present invention. The main components used in the invention include square shell 1, round shell 2, lens 3, lens holder 4, shrapnel 5, coil 6 and magnetic ring 7. The inner surface of the square shell 1 and the outer surface of the round shell 2 are fixed together; the lens 3 is embedded on the lens holder 4; the elastic sheet 5 connects the lens holder 4 and the round shell 2; the coil 6 is fixed on the outside of the lens holder 4 Surface; the magnetic ring 7 is fixed on the inner surface of the circular shell 2. The square shell and the round shell are connected by glue fastening. The square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com