Micro gas chromatographic column chip and preparation method thereof

A micro gas chromatography and chip technology, applied in the field of microelectronics and chromatographic analysis, can solve the problems of limited area of stationary phase, limited length of chromatographic column, insufficient separation of mixture, etc., and achieve the effect of increasing the surface area and reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

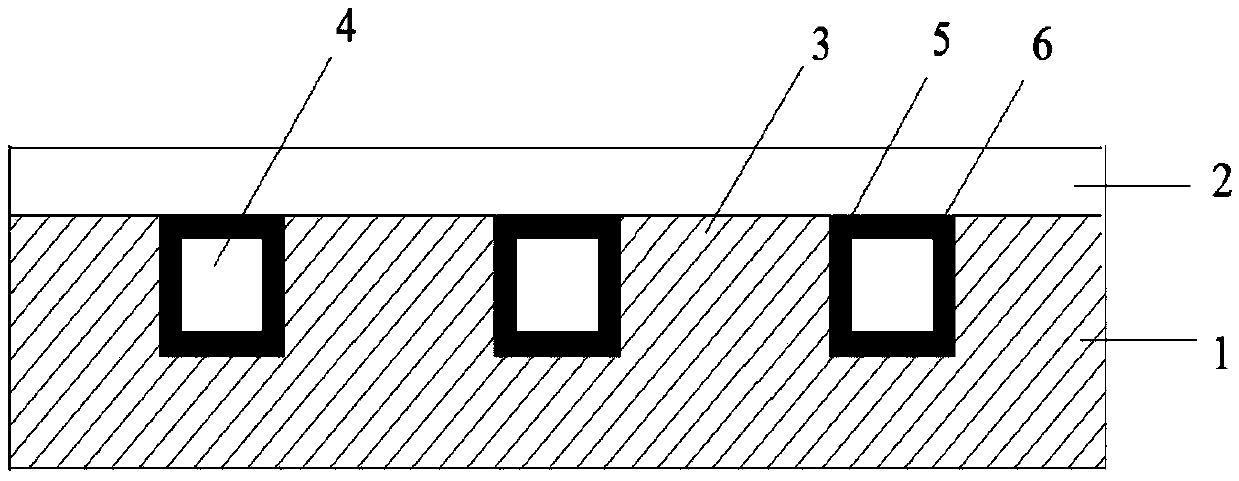

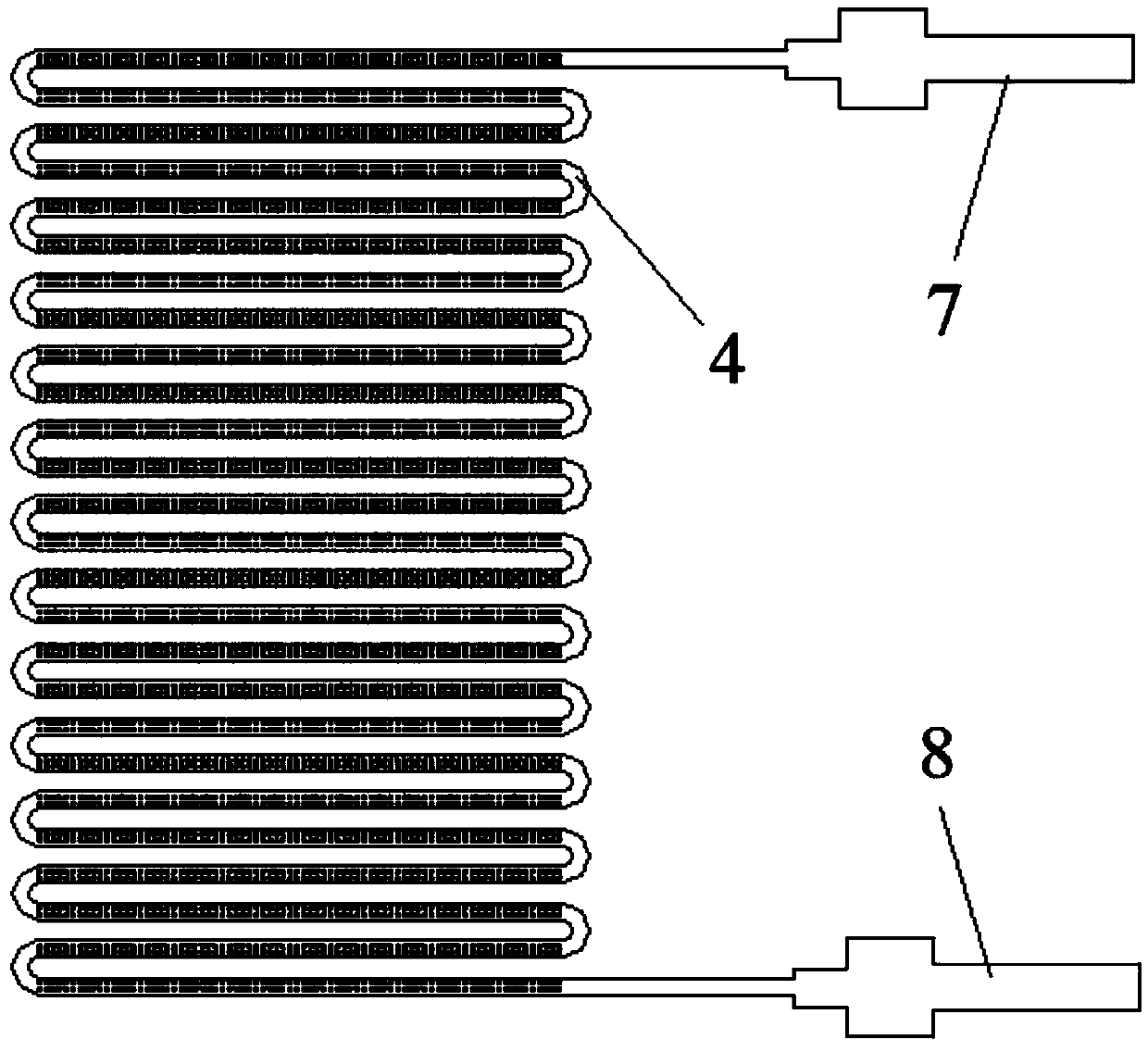

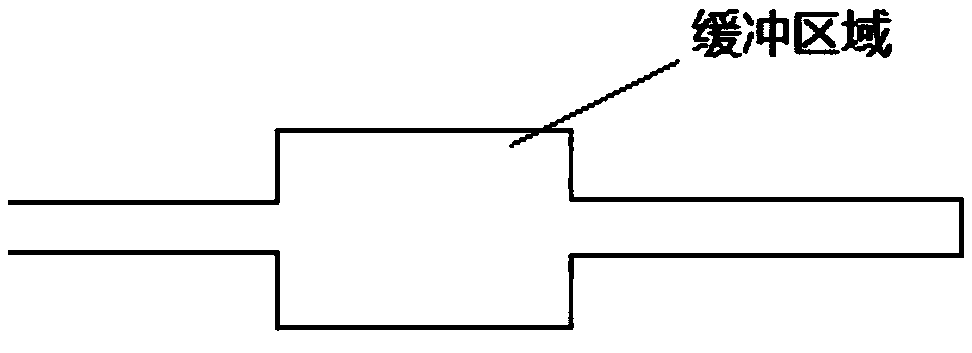

[0024] Such as figure 1 , 2 As shown, the micro-gas chromatographic column chip of the present invention includes a silicon substrate 1, has parallel channels 4 connected in sequence on the silicon substrate, and has silicon-based cylinders 3 regularly arranged in the channels, and the regular arrangement of the cylinders can make The increase of air pressure in the channel is conducive to increasing the gas flow rate and increasing the separation speed; the height of the cylinder is consistent with the depth of the channel, and an air inlet 7 and an air outlet 8 are opened on the silicon substrate, and the air inlet is located at one end of the channel. It is connected with the sampling system; the gas outlet is located at the other end of the channel and connected with the detector. Both the air inlet and the air outlet are designed as a groove that expands outward...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com