Hyperboloid chimney caps

A technology of chimney caps and hyperboloids, which is applied to the treatment of combustion products, combustion methods, exhaust gas devices, etc., can solve the problems of short overall service life, increased economic investment, and cumbersome use process, and achieves high smoke exhaust rate and high smoke emission. The effect of smooth air discharge and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

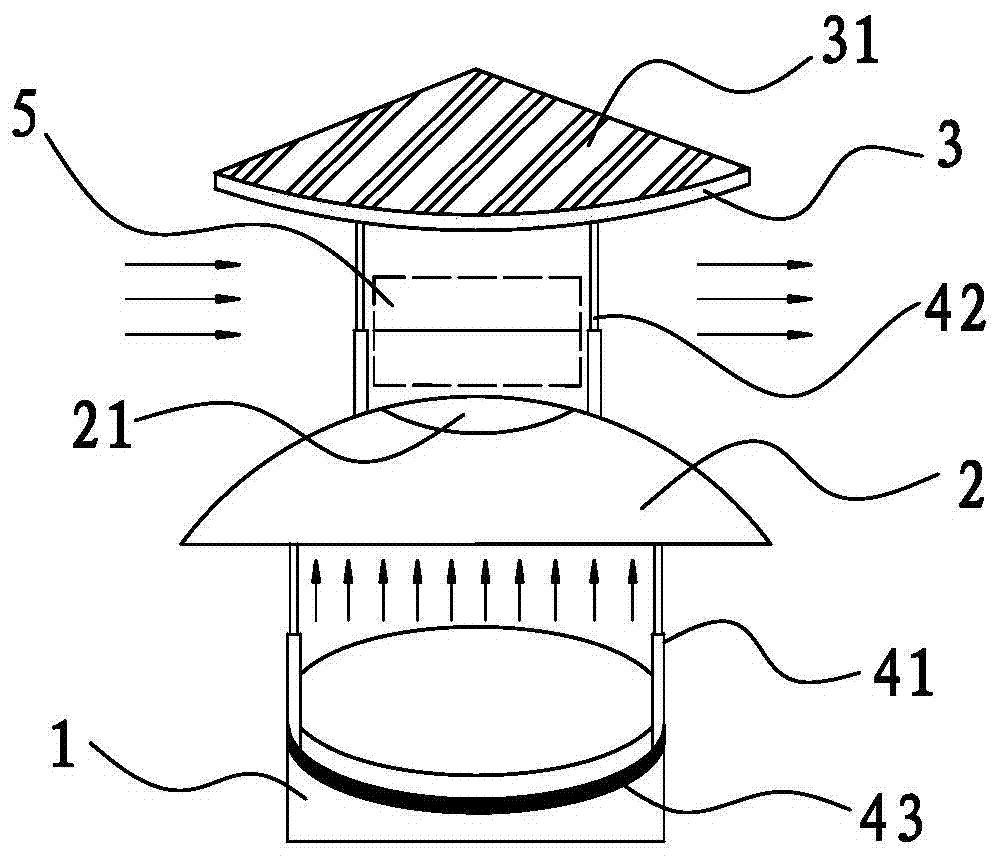

[0026] Such as figure 1 As shown, the present embodiment provides a hyperboloid chimney cap, comprising a first curved cover 3 and a second curved cover 2, the first curved cover 3 is fixedly connected to the second curved cover 2 via a first telescopic column 42, and the second curved cover 2 The clamping ring 43 is assembled and connected through the second telescopic column 41, and the clamping ring 43 is assembled and connected to the end position of the chimney 1. At the end position of the chimney 1 , the opening directions of the first curved surface cover 3 and the second curved surface cover 2 are opposite, and a top cover 31 is provided on the first curved surface cover 3 . A mask hole 21 is opened at the central position of the second curved mask 2 , and the area of the section of the mask hole 21 is smaller than the area of the opening section of the chimney 1 . The flue gas discharged from the chimney 1 first enters the second curved mask 2, at this time, the...

Embodiment 2

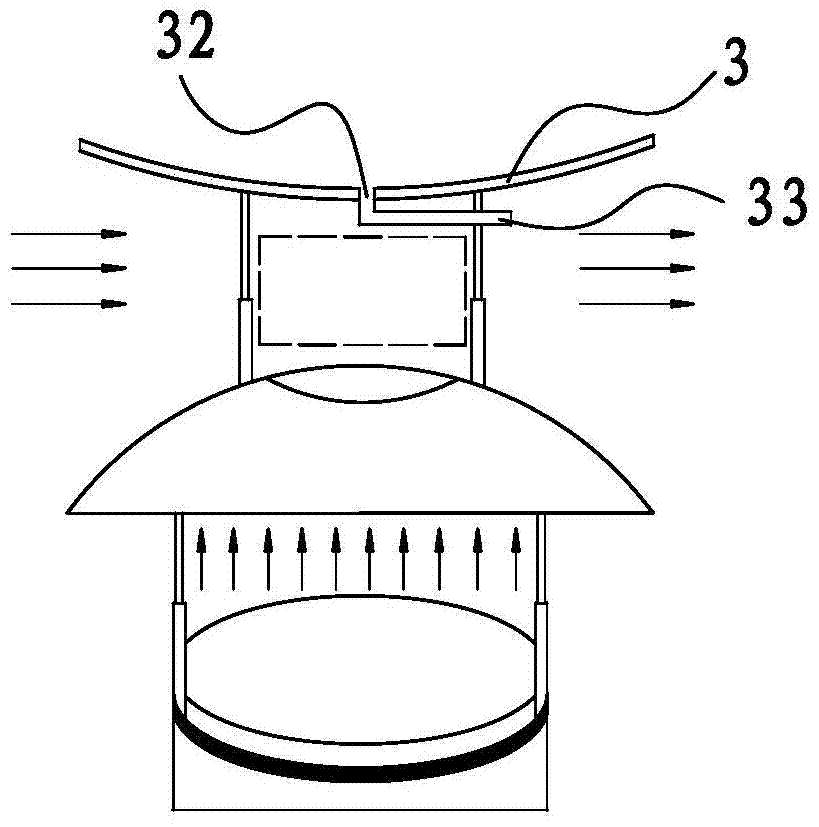

[0028] The difference between this embodiment and the first embodiment is that a drain hole 32 is provided in the center of the first curved surface cover 3 , and the drain hole 32 is connected to a drain pipe 33 . Like this, the rainwater on the first curved surface cover 3 can flow out through drainpipe 33, avoids the first curved surface cover 3 top water accumulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com