Electric pinch valve

A pinch valve, electric technology, applied to valve details, diaphragm valves, valve devices, etc., can solve the problems of small clamping force, large on-off noise, inconvenient installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

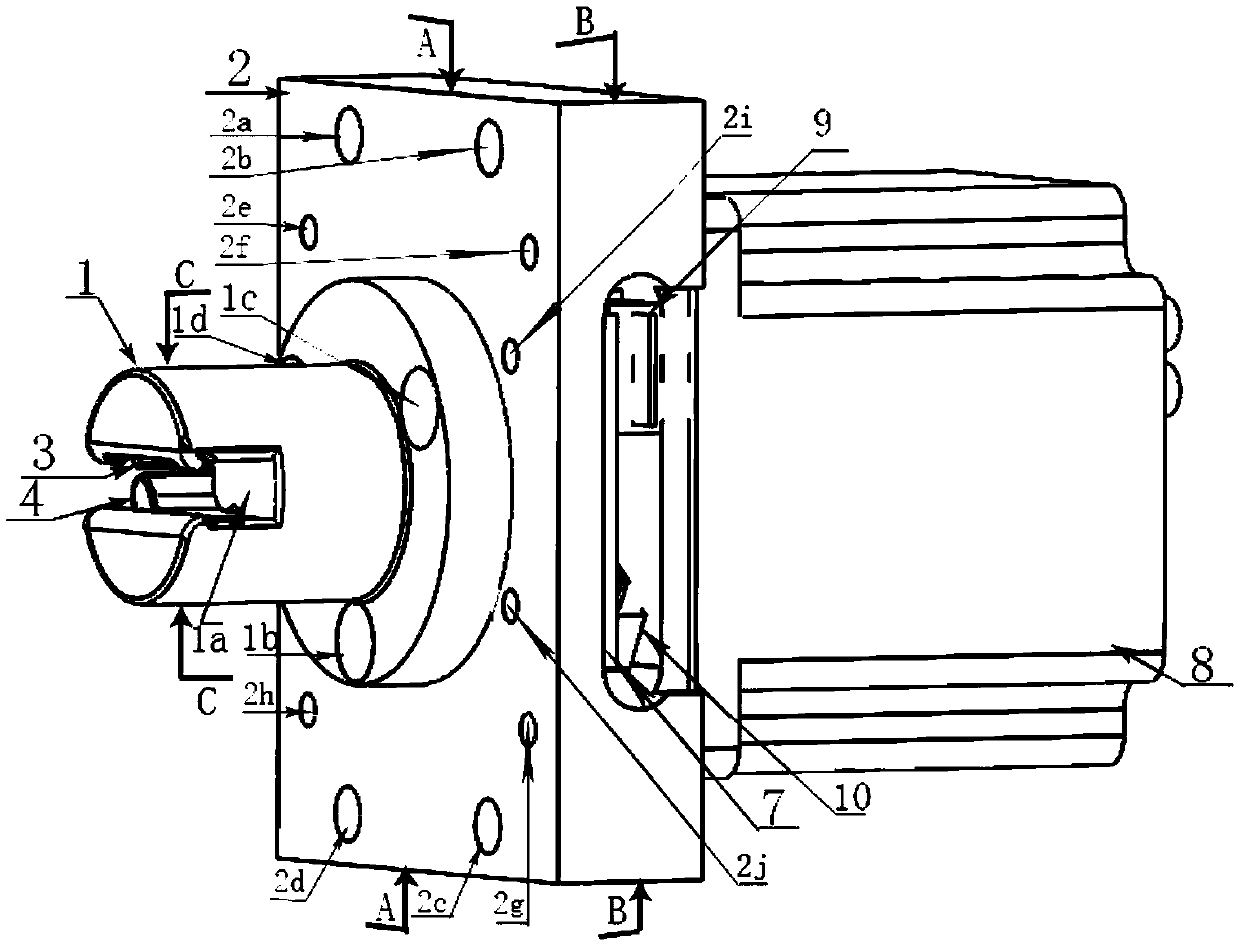

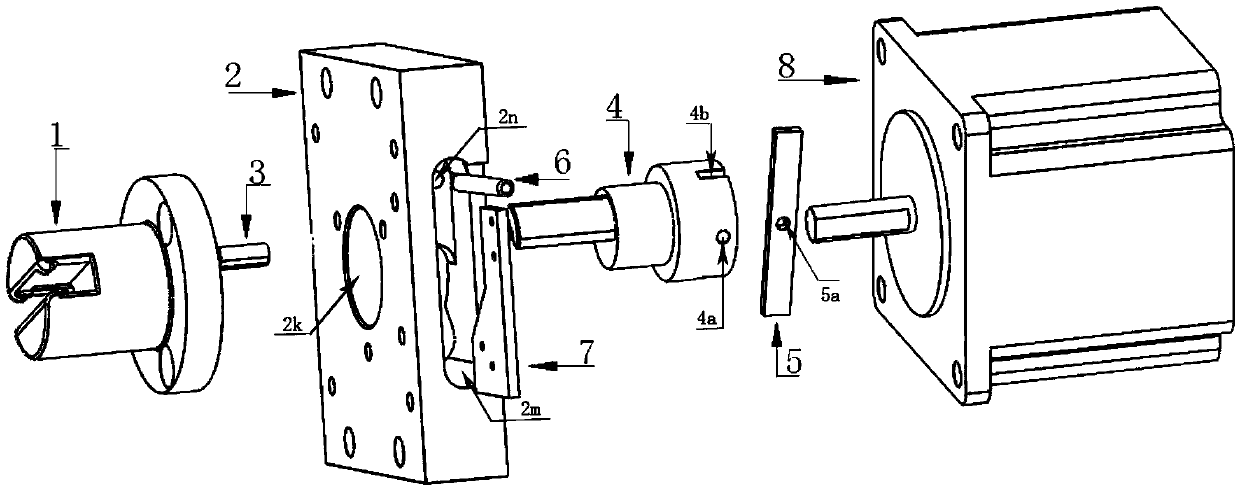

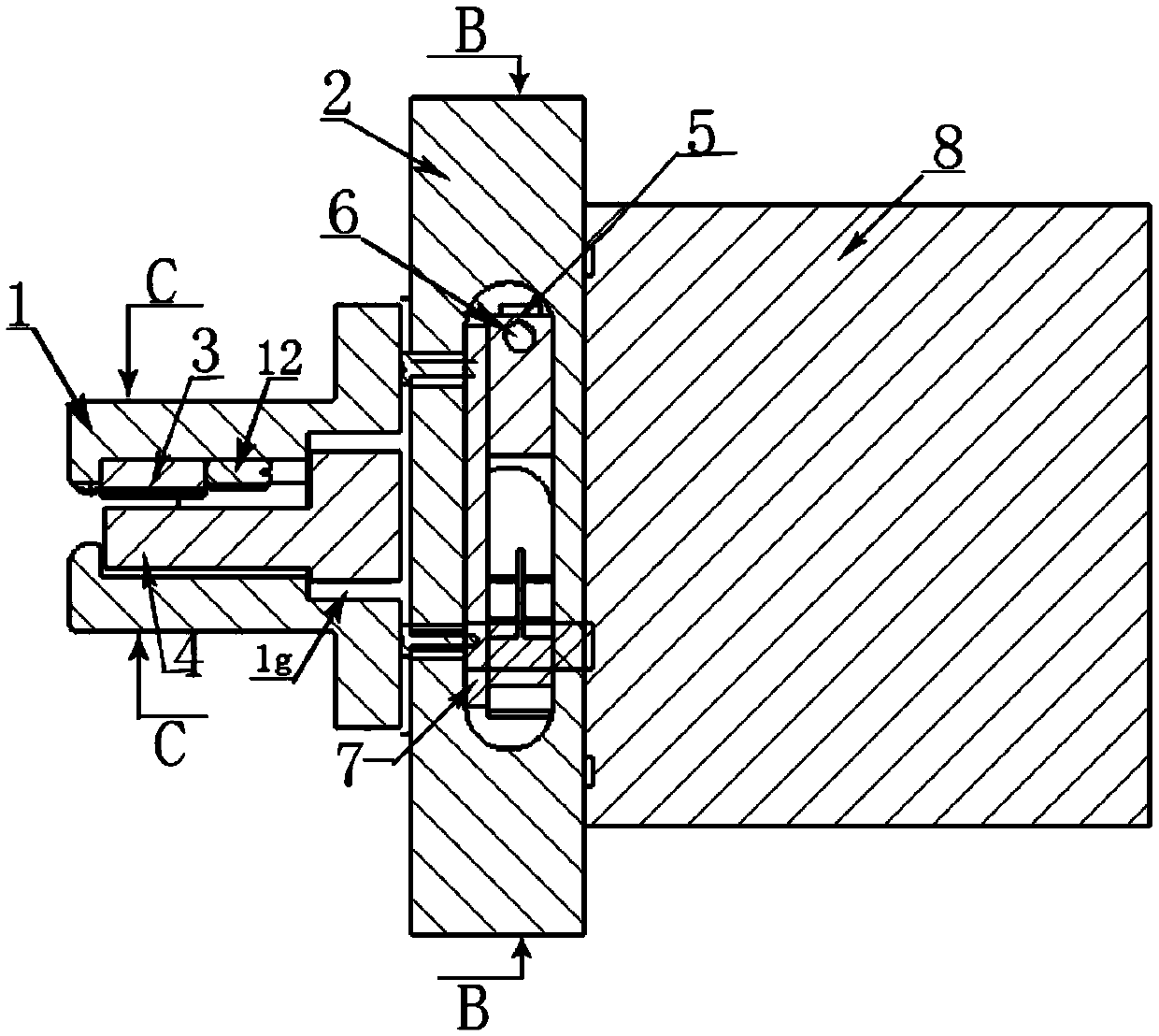

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] The electric pinch valve of the present invention includes a hose clamp assembly, a movable valve assembly, a limiting device assembly and a connecting plate 2 . The connecting plate 2 is an intermediate device of the hose clamp assembly, the movable valve assembly, and the limit device assembly. The hose clamp assembly is installed at the front center of the connecting plate 2, and the movable valve assembly is inserted into the central circular hole 2k on the back of the connecting plate 2 and fixed on the back of the connecting plate 2. The limiting device assembly is embedded in the oval cavity 2m on the right side of the connecting plate 2 .

[0020] The hose clamp assembly includes a clamp housing 1 , a retaining post 3 and a second jacking wire 12 . Such as figure 1 As shown, the front end surface of the chuck housing 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com