Oil film rigidity-adjustable fluid dynamic and static pressure slide bearing

A sliding bearing and adjustable technology, used in bearings, liquid cushion bearings, shafts and bearings, etc., can solve the problems of wear and can't adjust the size at will, and achieve high control accuracy, improve dynamic running performance, and improve dynamic pressure effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

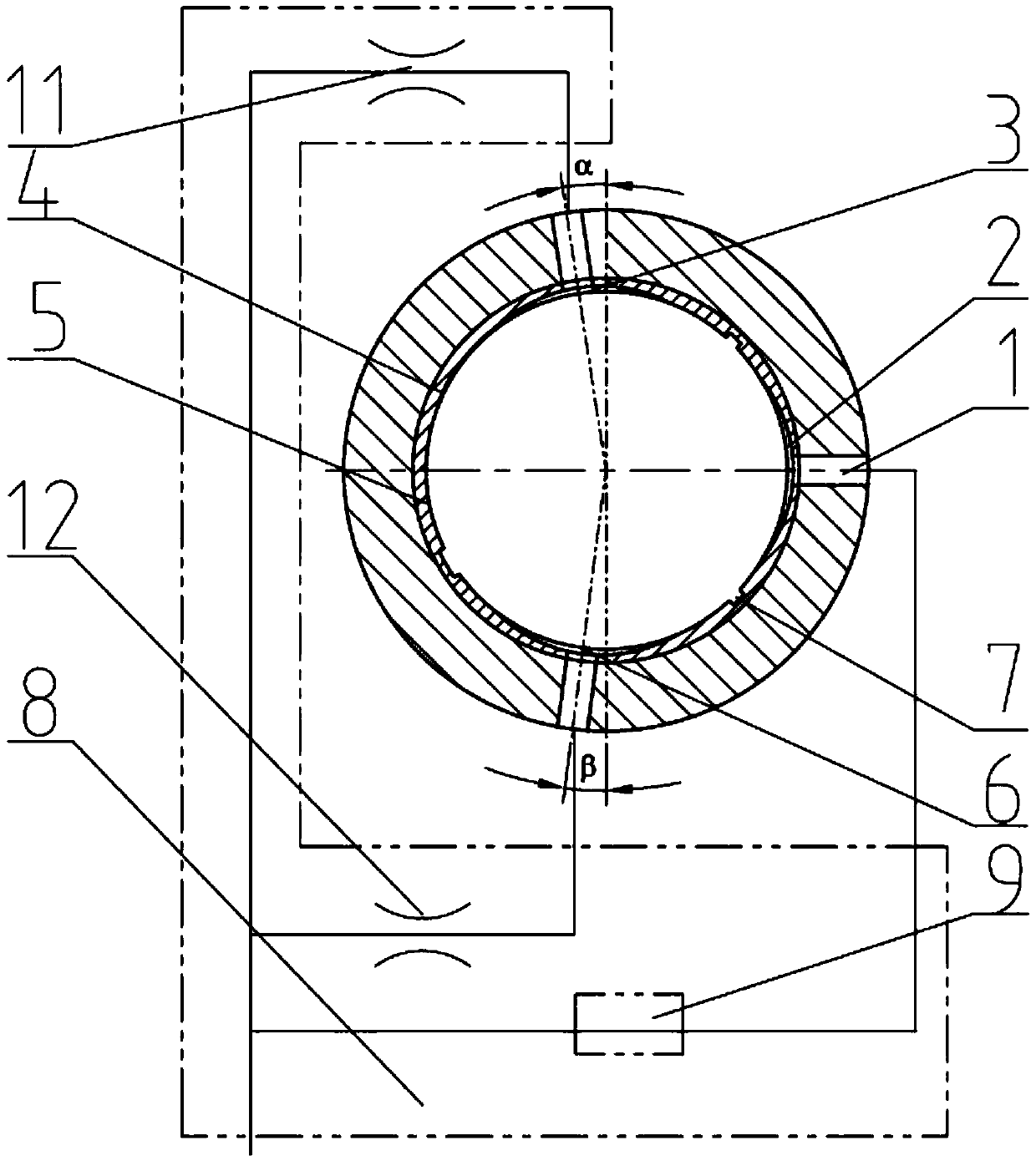

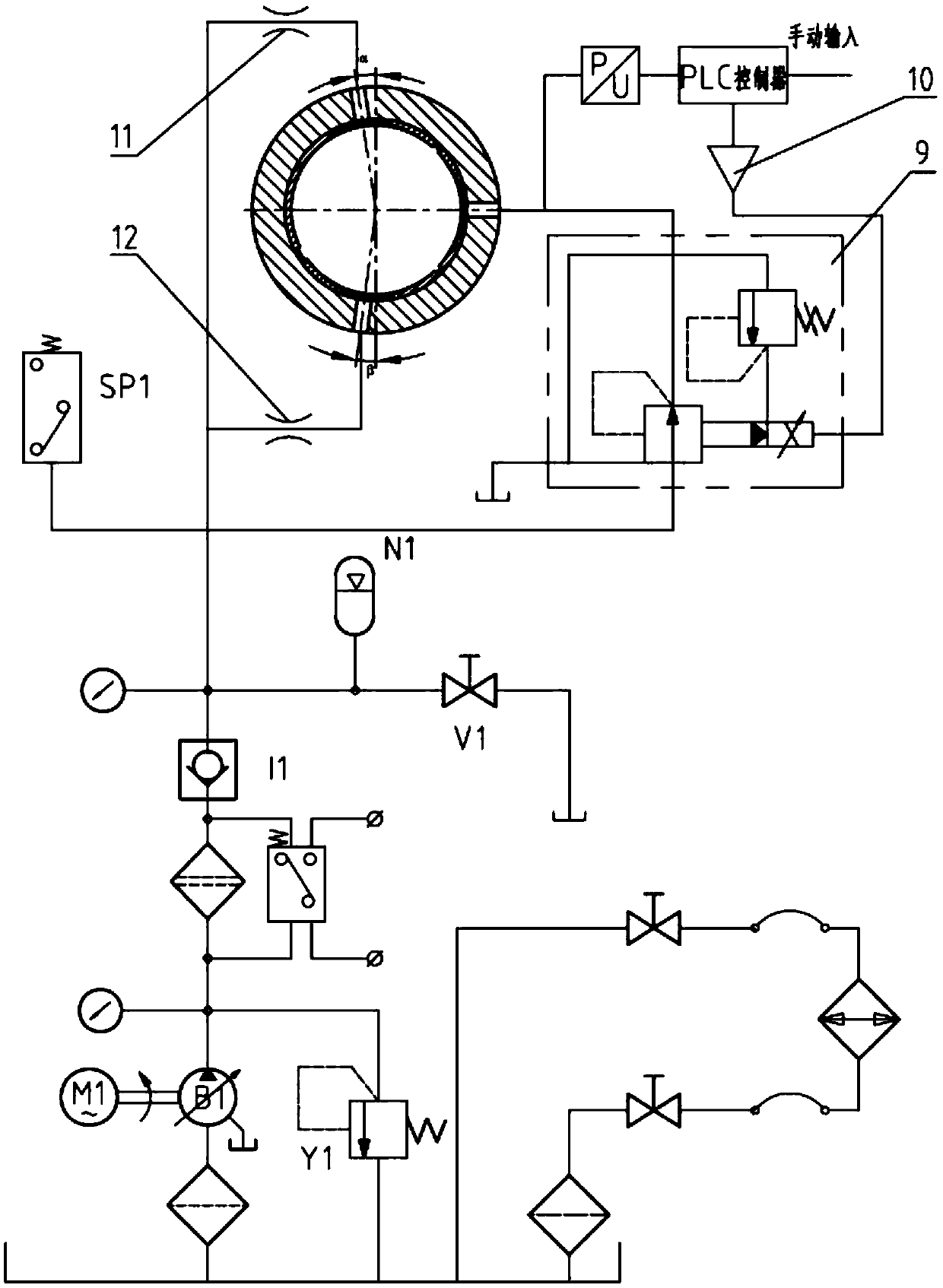

[0015] Such as figure 1 , as shown in 2, the hydrodynamic and static pressure sliding bearing with adjustable oil film rigidity of the present invention includes a front static pressure oil chamber 2, an upper static pressure oil chamber 3, a lower static pressure oil chamber 6, a dynamic pressure chamber 5, three oil inlets Hole 1, three axial oil return tanks 7, oil supply system 8, electro-hydraulic servo control valve 9, signal amplifier 10, capillary restrictor A11, capillary restrictor B12, pressure sensor P / U, oil pump motor M1, oil pump B1, safety valve Y1, one-way valve I1, pressure relay SP1, accumulator N1, stop valve V1.

[0016] A wedge-shaped chamber 4 is opened between the upper static pressure oil chamber 3 and the dynamic pressure chamber 5. The cross section of the wedge-shaped chamber 4 is an Archimedes spiral oil chamber profile. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com