Sleeve nut, fastener and installation method of fastener

A sleeve nut and installation method technology, applied in the direction of threaded fasteners, nuts, connecting components, etc., can solve the problems of poor nut tightening effect, inability to use thin-walled profiles, etc., to achieve easy control of installation quality and increase connection. The effect of reliability, cost reduction and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

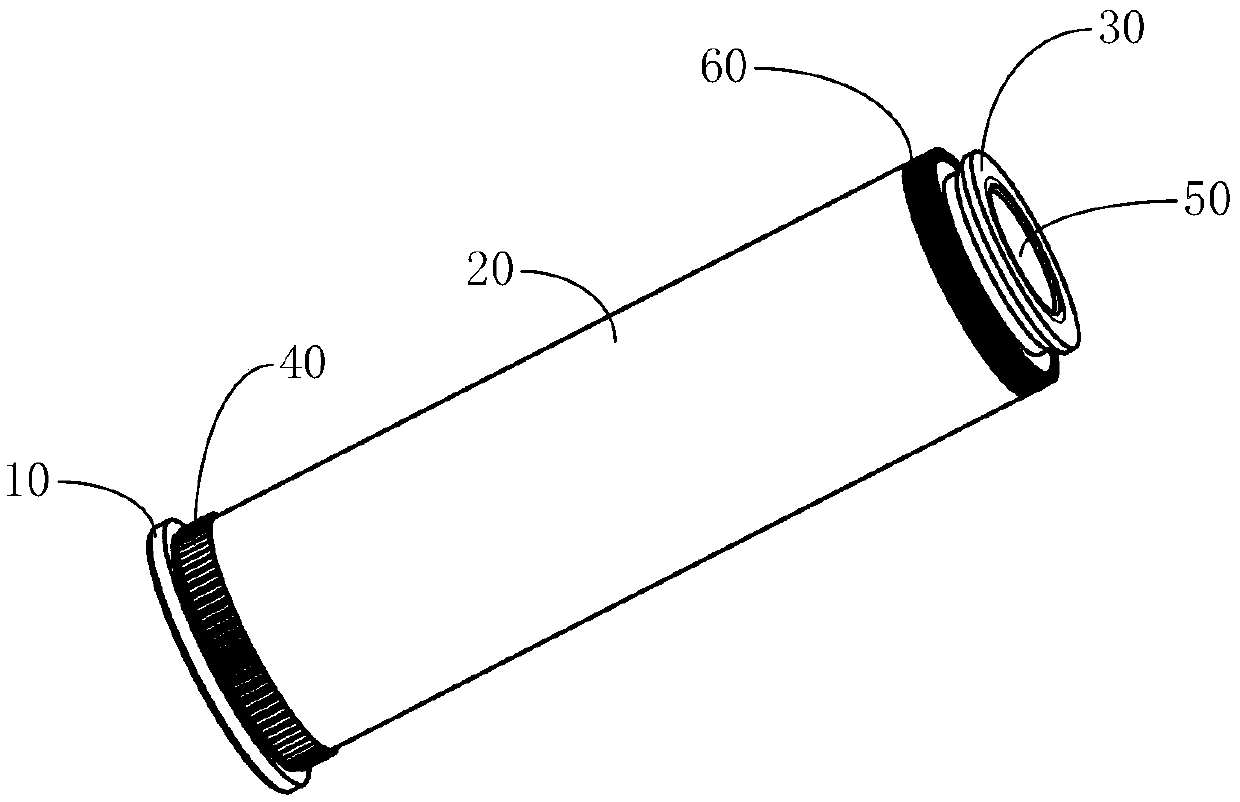

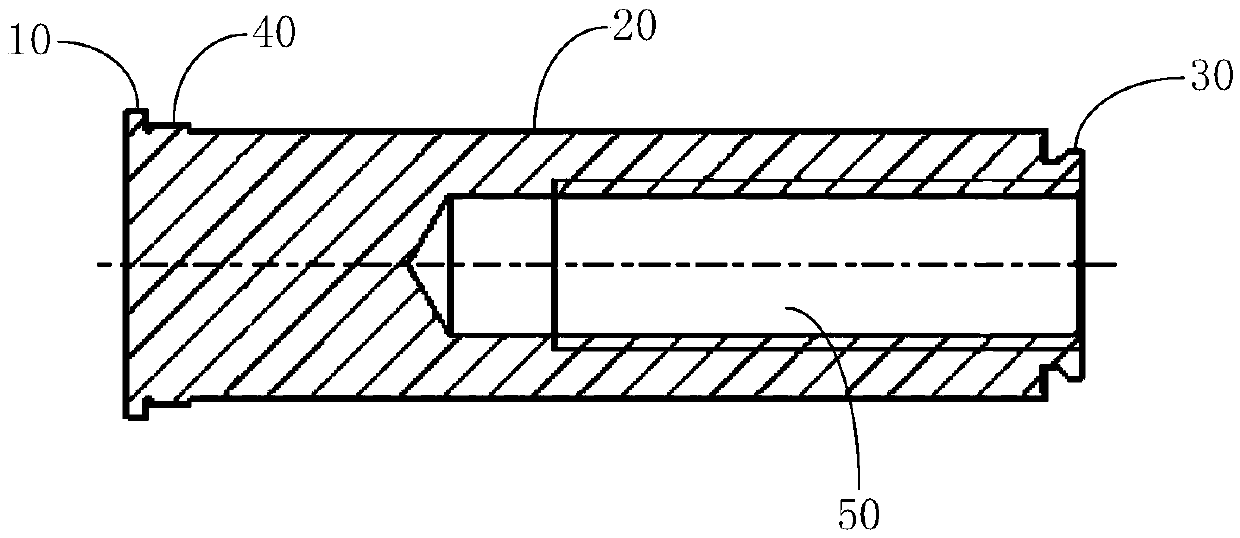

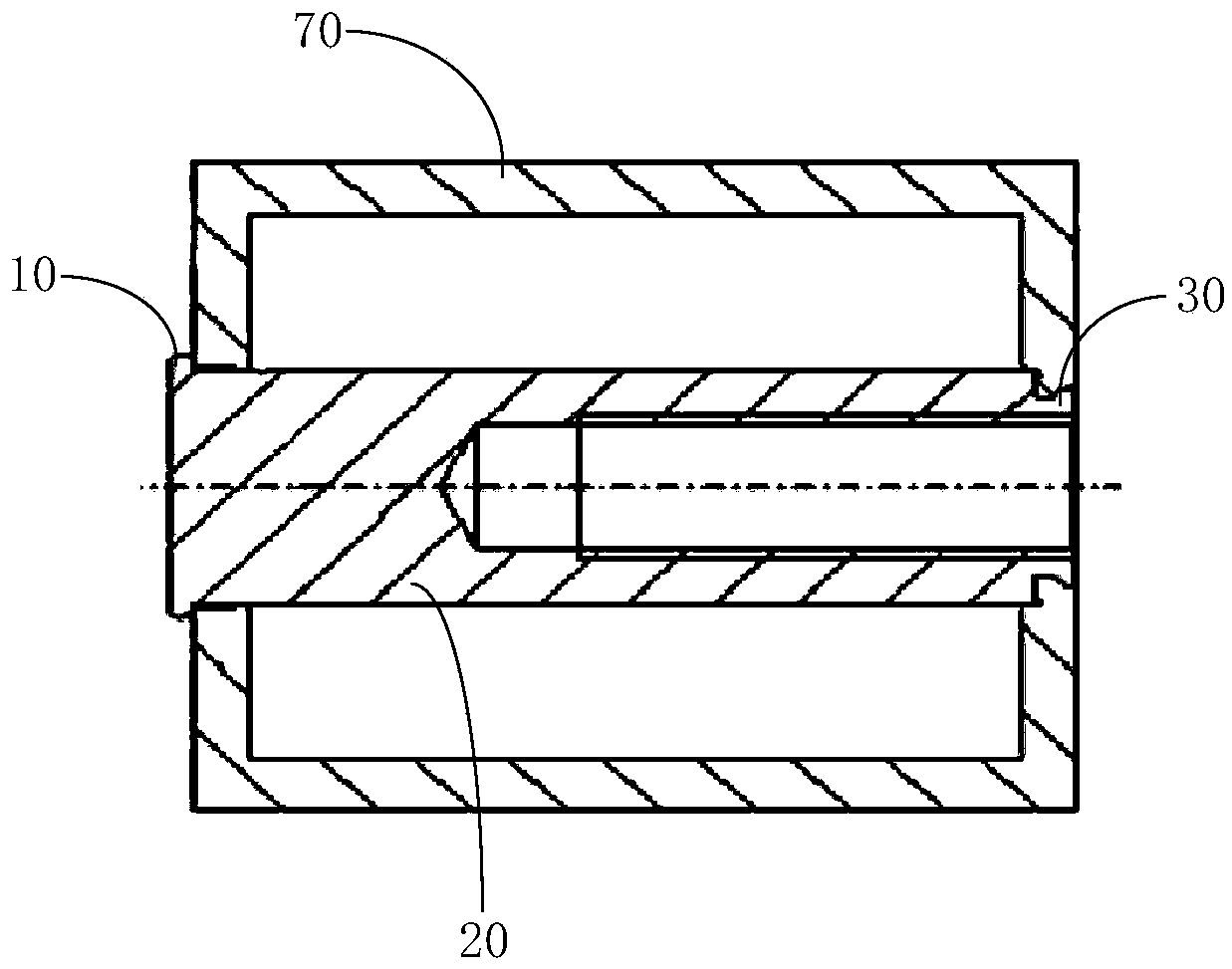

[0033] The sleeve nut provided by the invention, such as figure 1 and figure 2 As shown, it includes a base 10, a cylinder 20 and an interlock key 30 arranged in sequence, the outer diameter of the base 10 is larger than the outer diameter of the cylinder 20, and one end of the cylinder 20 close to the base 10 is provided with The first flower teeth 40 are arranged along the circumferential direction; a threaded hole 50 is provided on the inner side of the barrel 20 close to the interlocking key 30 . In the sleeve nut provided by the present invention, one end where the base 10 is located is in an interference connection with the profile 70 through the first spline 40, and the end where the interlock key 30 is located is self-fastened through the flow of the material and the profile, thereby realizing the connection between the sleeve nut and the profile. There is no requirement for the wall thickness of the fastening connection of the profile 70, even for thin-walled profil...

Embodiment 2

[0048] Please focus on reference Figure 6 , the difference between this embodiment and Embodiment 1 is that: the inside of the barrel 20 is a through hole 53, please refer to Figure 7 , in this embodiment, the combination of the fastener and the pair of fittings 51 is as follows: the second bolt 54 passes through the pair of fittings 51 and the through hole 53 in turn, and is fixed with a nut 55 after passing through, which can also achieve the purpose of fastening .

Embodiment 3

[0050] Please focus on reference Figure 8a The difference between this embodiment and Embodiment 1 is that the specific form of the interlock key 30 is different. In this embodiment, the top sheet of the interlock key 30 is pressed outward to form a fixed connection with the profile 70 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com