Turbocharger intermediate

A turbocharger, intermediate technology, applied in the direction of machines/engines, liquid fuel engines, parts of pumping devices for elastic fluids, etc. and other problems, to achieve the effects of stable and reliable operating temperature, increased heat dissipation area, and large stable working range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

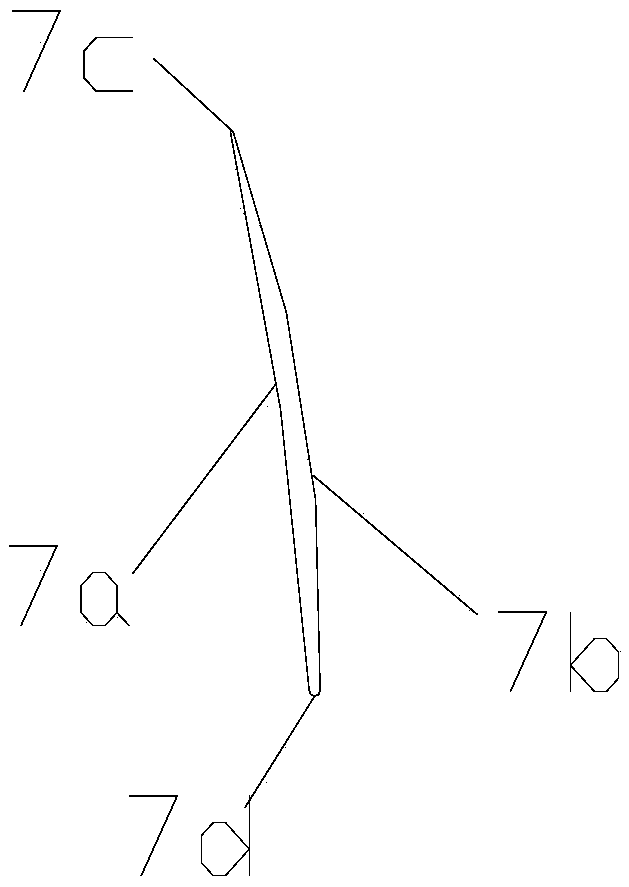

[0028] like figure 1 and figure 2 , a turbocharger intermediate body, including an intermediate body 1, one end of the intermediate body 1 is provided with a diffuser plate 2, the intermediate body 1 and the diffuser plate 2 are integrally formed, and the center of the diffuser plate 2 An impeller hole 6 for installing the impeller 11 is provided, and a diffuser is provided on the diffuser plate 2, and the diffuser includes a vaneless diffuser 8 close to the impeller hole 6 and a vane diffuser 12 far away from the impeller hole 6, The edges of the vaneless diffuser 8 and the vane diffuser 12 are connected, and the vane diffuser 12 includes a plurality of diffuser vanes 7 , and the diffuser vanes 7 are fixed on the diffuser plate 2 . The integrated intermediate body 1 and diffuser plate 2 simplify the structure, reduce the processing cost and time, simplify the assembly process, ensure the concentricity of the holes and the overall assembly accuracy, and eliminate the noise g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com