A production logging flexible sub

A flexible sub-joint and logging technology, used in surveying, wellbore/well components, construction, etc., can solve problems such as downhole resistance, avoid instrument damage, and solve the effect of downhole resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

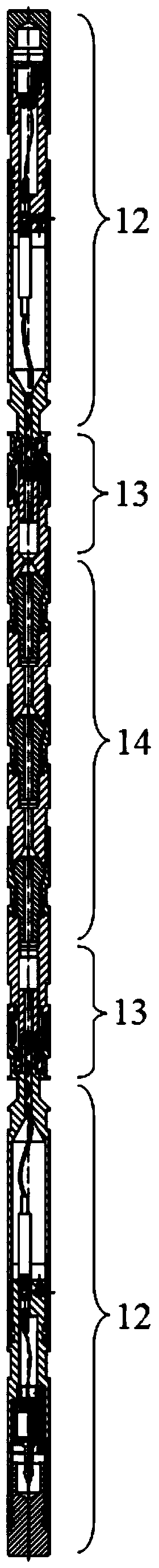

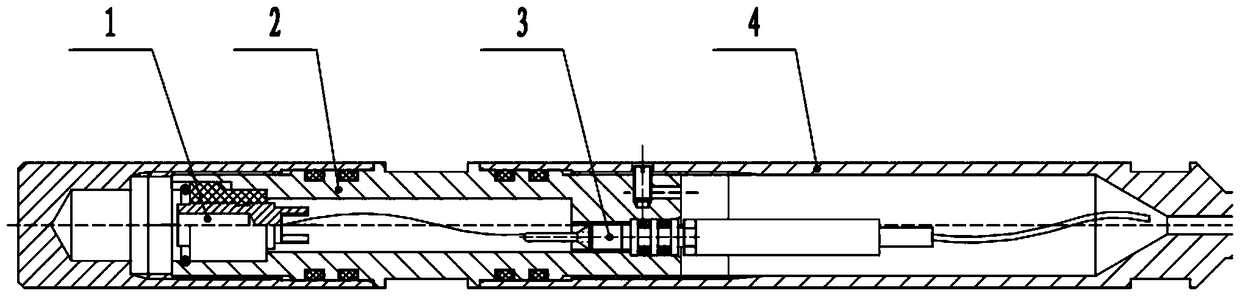

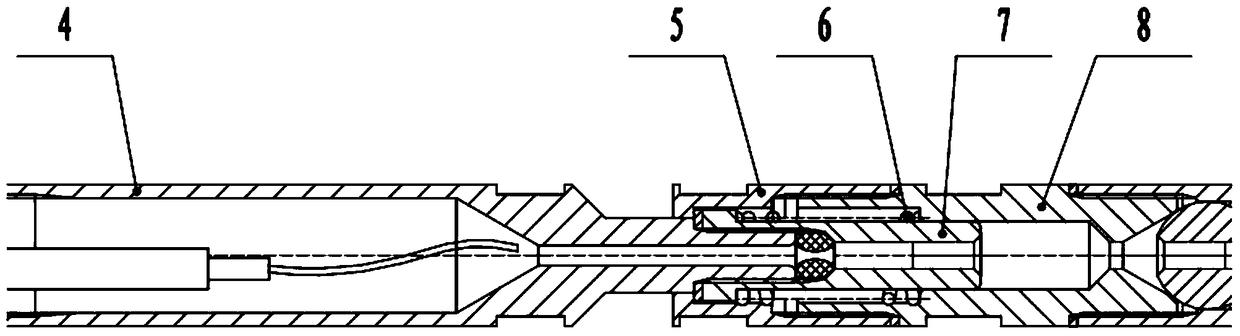

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] The production logging flexible nipple provided by the present invention includes two sets of sealing components 12, two sets of buffer components 13 and one set of flexible components 14, wherein the two sets of buffer components have the function of anti-shocking, and the flexible components are composed of multiple flexible sub-sections , the number of flexible subsections can be increased or decreased according to site requirements, thereby changing the flexibility index of the flexible component. The production logging flexible subsection can be installed at any position of the instrument string, which can change the flexibility of the instrument string and reduce the possibility of the instrument string encountering resistance. see figure 1 , the connection sequence of the production logging flexible nipple from left to right is: the sealing asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com