Energy-saving environment-friendly air supply branch pipe

An energy-saving and environmental-friendly technology with branch pipes, applied in blast furnace details, furnace types, blast furnace parts, etc., can solve problems such as energy waste, large energy waste, cracks in refractory materials, etc., to improve the operating environment, reduce pollution emissions, and increase hot air temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments given in the drawings, but the embodiments do not constitute any limitation to the present invention.

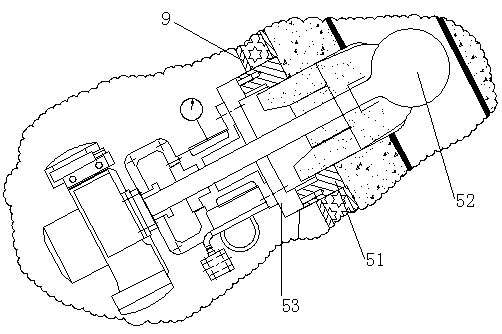

[0023] See figure 1 , Energy-saving and environmentally-friendly air supply branch pipe, composed of gooseneck 1, compensator 2, middle section 3, lower section 6, and straight blown pipe 7. Among them, two compensators 2 are installed, one is set in gooseneck 1 and middle section 3. The other is set between the middle section 3 and the lower section 6; the middle section 3 is equipped with a pressure measuring device 4 and a flow regulating device 5; the inner side of the metal steel shell 9 of the air supply branch pipe is provided with a multiple thermal insulation structure 8 .

[0024] See figure 2 , The pressure measuring device 4 consists of two upper pressure measuring tubes 41 and lower pressure measuring tubes 42; the upper pressure measuring tube 41 and the lower pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com