Optical film with adhesive and production method thereof, and method for producing image display device

A technology for image display devices and optical films, applied in adhesive types, chemical instruments and methods, ester copolymer adhesives, etc., can solve problems such as uneven display, achieve pollution suppression, low fluidity, and display suppression uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148]

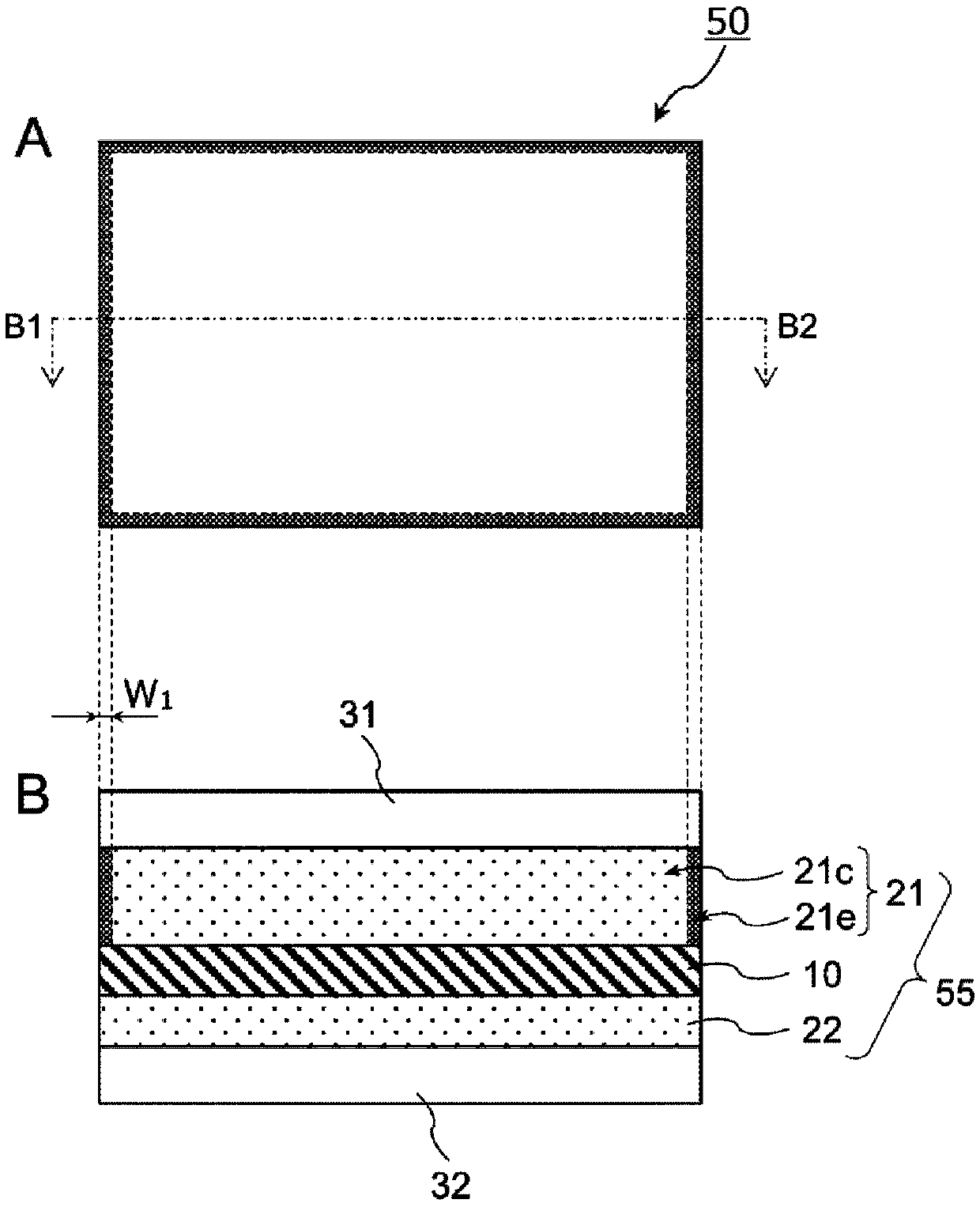

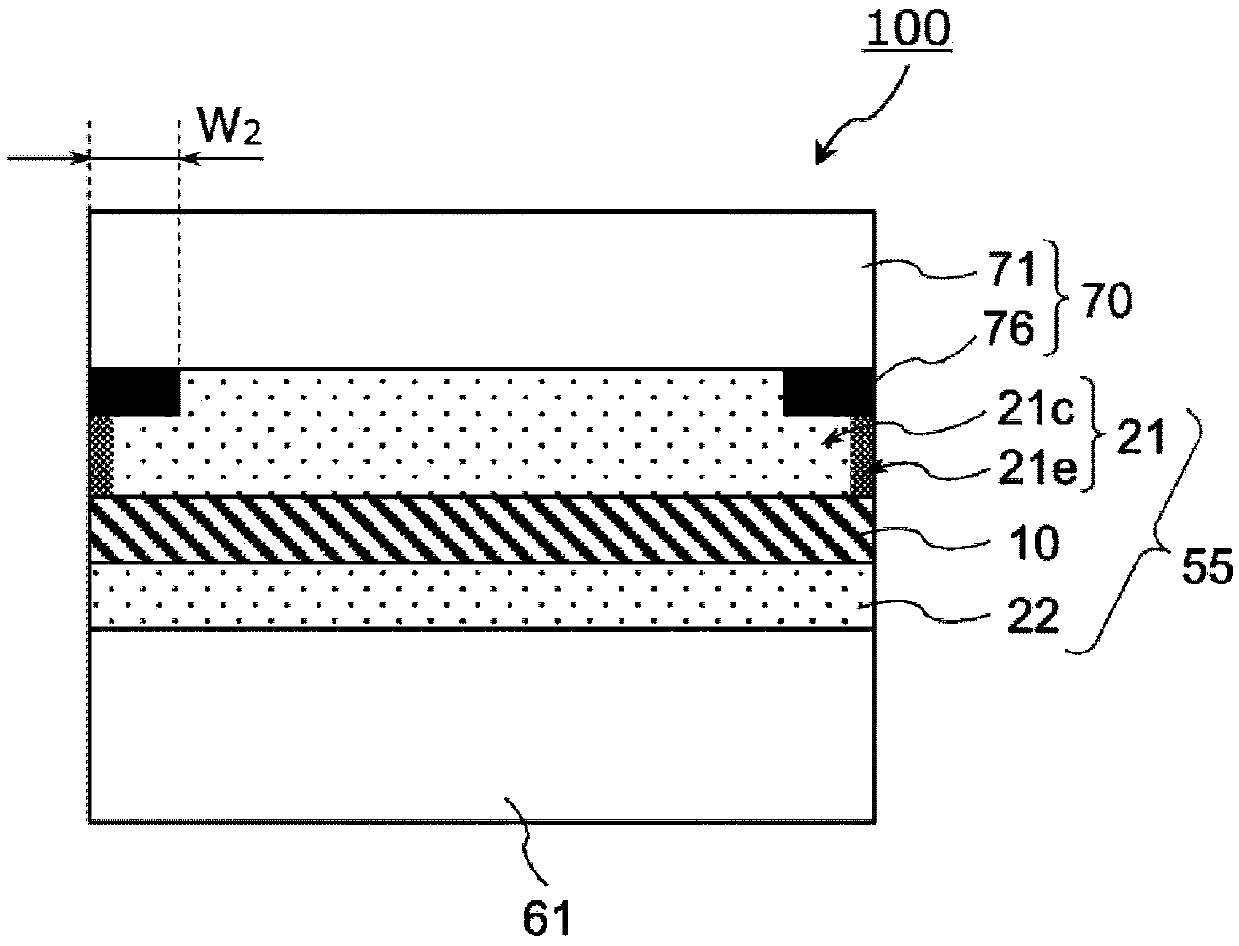

[0149] The pressure-sensitive adhesive sheet X was bonded to one surface of the polarizing plate as a cell-side pressure-sensitive adhesive layer. Then, the pressure-sensitive adhesive sheet A was bonded on the other surface of the polarizing plate as a visible-side pressure-sensitive adhesive layer. In this way, an adhesive sheet X with a thickness of 20 μm was attached to one side of a polarizing plate, an adhesive sheet A with a thickness of 150 μm was attached to the other side, and a separator was attached to each adhesive sheet in a releasable manner. A polarizing plate with an adhesive on both sides of the sheet. This double-sided adhesive-attached polarizing plate was punched out to a size of 50 mm×80 mm using a Thomson knife. After 50 sheets of punched double-sided polarizing plates with adhesive are stacked, use a hand-held UV lamp (energy density of UVA: 300mW / cm 2 ) Irradiated from the side of the polarizing plate with a cumulative light intensity of a...

Embodiment 2~4

[0154] A polarizing plate with an adhesive on both sides was produced in the same manner as in Example 1 except that the PSA sheets B to D were used as the visible-side pressure-sensitive adhesive layer, and an image display device was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com