Color-changing indicating device and transparent ink

A technology of color change indication and transparent ink, applied in ink, material analysis by observing the influence on chemical indicators, household appliances, etc., can solve the problem of color change indicating device indicating effect, inconsistency, and non-neutrality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

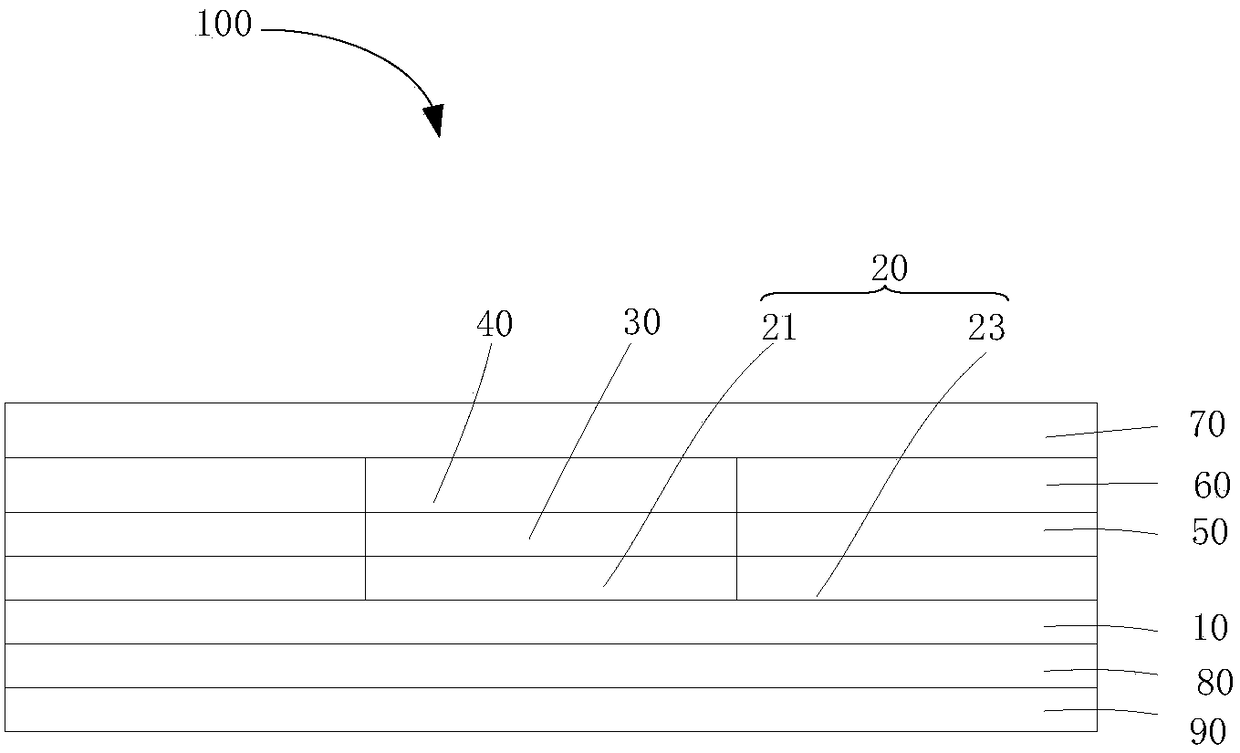

[0062] The structure of the color change indicating device of embodiment 1 is as follows figure 1 As shown, it includes a base layer 10, an indicator layer 20, a protective layer 30, an isolation layer 40, a release layer 50, a first adhesive layer 60, a barrier layer 70, a second adhesive layer 80, and a peeling layer 90.

[0063] Among them, the material of the base layer 10 is PET with a thickness of 0.1 mm; the material of the indicator layer 20, the protective layer 30, and the isolation layer 40 is polyvinyl butyral (PVB) with a thickness of 0.02 mm; the material of the release layer 50 It is silicone oil with a thickness of 0.01mm; the material of the first adhesive layer 60 is acrylic resin with a thickness of 0.01mm; the material of the barrier layer 70 is polyethylene terephthalate with a thickness of 0.05mm; the second adhesive layer The material of 80 is acrylic resin with a thickness of 0.01 mm; the material of the release layer 90 is cellophane containing silicone o...

Embodiment 2

[0069] The structure of the color change indicator device of embodiment 2 is as follows figure 1 As shown, it includes a base layer 10, an indicator layer 20, a protective layer 30, an isolation layer 40, a release layer 50, a first adhesive layer 60, a barrier layer 70, a second adhesive layer 80, and a release layer 90.

[0070] Among them, the material of the base layer 10 is polyethylene terephthalate with a thickness of 0.15mm; the material of the indicator layer 20, the protective layer 30, and the isolation layer 40 is polyvinyl alcohol (PVA) with a thickness of 0.05mm; The material of the type layer 50 is polyvinyl alcohol with a thickness of 0.015 mm; the material of the first adhesive layer 60 is polyurethane with a thickness of 0.05 mm; the material of the barrier layer 70 is polyethylene terephthalate with a thickness of 0.1 mm The material of the second adhesive layer 80 is acrylic resin with a thickness of 0.05 mm; the material of the peeling layer 90 is cellophane ...

Embodiment 3

[0076] The structure of the color change indicating device of embodiment 3 is as follows figure 1 As shown, it includes a base layer 10, an indicator layer 20, a protective layer 30, an isolation layer 40, a release layer 50, a first adhesive layer 60, a barrier layer 70, a second adhesive layer 80, and a release layer 90.

[0077] Among them, the material of the base layer 10 is aluminum oxide foil with a thickness of 0.1 mm; the material of the indicator layer 20, the protective layer 30, and the isolation layer 40 is hydroxyethyl cellulose (HEC) with a thickness of 0.07 mm; the material of the release layer 50 It is emulsified paraffin wax with a thickness of 0.02mm; the material of the first adhesive layer 60 is acrylic resin with a thickness of 0.02mm; the material of the barrier layer 70 is polypropylene with a thickness of 0.15mm; the material of the second adhesive layer 80 is polyurethane , The thickness is 0.08mm; the material of the peeling layer 90 is cellophane conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com