Preparation method of silicone rubber pad

A technology of silicone rubber and compounded rubber, applied in the field of thermally conductive polymer composite materials, can solve the problems of increasing production costs, failing to meet the requirements of thermal conductivity, and graphene orientation, etc., to enhance surface viscosity, speed up vulcanization rate, improve The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

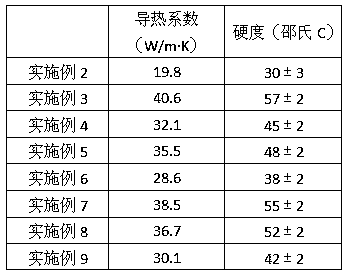

Examples

Embodiment 1

[0039] A preparation method for a silicone rubber pad, comprising the following steps:

[0040] (1) Preparation of nano-carbon-silicone rubber mixture: Add 100 parts by weight of silicone rubber into a kneader, then add 100-400 parts by weight of nano-carbon material, and knead evenly to obtain a nano-carbon-silicone rubber mixture.

[0041] (2) Preparation of rubber compound: first add the nano-carbon-silicone rubber mixture into the open mill, and then add 10-300 parts by weight of inorganic heat-conducting powder, 1-10 parts by weight of catalyst and 1-10 parts by weight The mixture composed of dimethyl silicone oil and hydrogen-containing silicone oil is kneaded for 10-60 minutes, and the mixed rubber can be obtained after the kneading is completed.

[0042] (3) Put the mixed rubber into a mold, and then use a physical method to orient the mixed rubber to obtain a sample pad in which nano-carbon materials are oriented in silicone rubber; the mold is preferably a square mol...

Embodiment 2

[0051] A preparation method for a silicone rubber pad, comprising the following steps:

[0052] (1) Preparation of nano-carbon-silicone rubber mixture: Add 100g of raw silicone rubber to the kneader, and then add 100g of nano-carbon material, which is a mixture of graphene and flake graphite, and knead evenly to obtain Nano carbon-silicone rubber mixture.

[0053] (2) Preparation of compound rubber: firstly add the nano-carbon-silicone rubber mixture into the open mill for milling, and after 5 minutes of milling, add 10g of metal aluminum powder, 1g of tert-butyl peroxybenzoate and 1g of The mixture composed of simethicone oil and hydrogen-containing silicone oil is kneaded for 10 minutes, and the mixed rubber can be obtained after kneading is completed.

[0054] Wherein, simethicone oil with a viscosity of 500 mPa·s is added to the tert-butyl peroxybenzoate, and the mass percentage of tert-butyl peroxybenzoate to simethicone oil is 1:10. In the mixture composed of simethico...

Embodiment 3

[0058] A preparation method for a silicone rubber pad, comprising the following steps:

[0059] (1) Preparation of nano-carbon-silicone rubber mixture: Add 100g of silicone rubber raw rubber into the kneader, and then add 400g of nano-carbon material, which is a mixture of graphene and carbon nanotubes, and knead evenly A nano-carbon-silicone rubber mixture is obtained.

[0060] (2) Preparation of compound rubber: firstly, add the nano-carbon-silicone rubber mixture into the open mill for kneading. After 20 minutes of kneading, add 300g of metal aluminum powder, 10g of tert-butyl peroxybenzoate and 10g of The mixture composed of simethicone oil and hydrogen-containing silicone oil is kneaded for 60 minutes, and the mixed rubber can be obtained after kneading is completed.

[0061] Wherein, simethicone oil with a viscosity of 5000 mPa·s is added to the tert-butyl peroxybenzoate, and the mass percentage of tert-butyl peroxybenzoate and simethicone oil is 10:100. In the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com