Device and method for recovering low-concentration spinning waste liquid produced during preparation of hollow fiber membrane

A waste liquid recycling and low-concentration technology, which is applied in chemical instruments and methods, textile industry wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems of incomplete retention of additives, increased magazine content, poor economic efficiency, etc. , to achieve the effect of reducing the accumulation of salt, reducing the content of salt, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

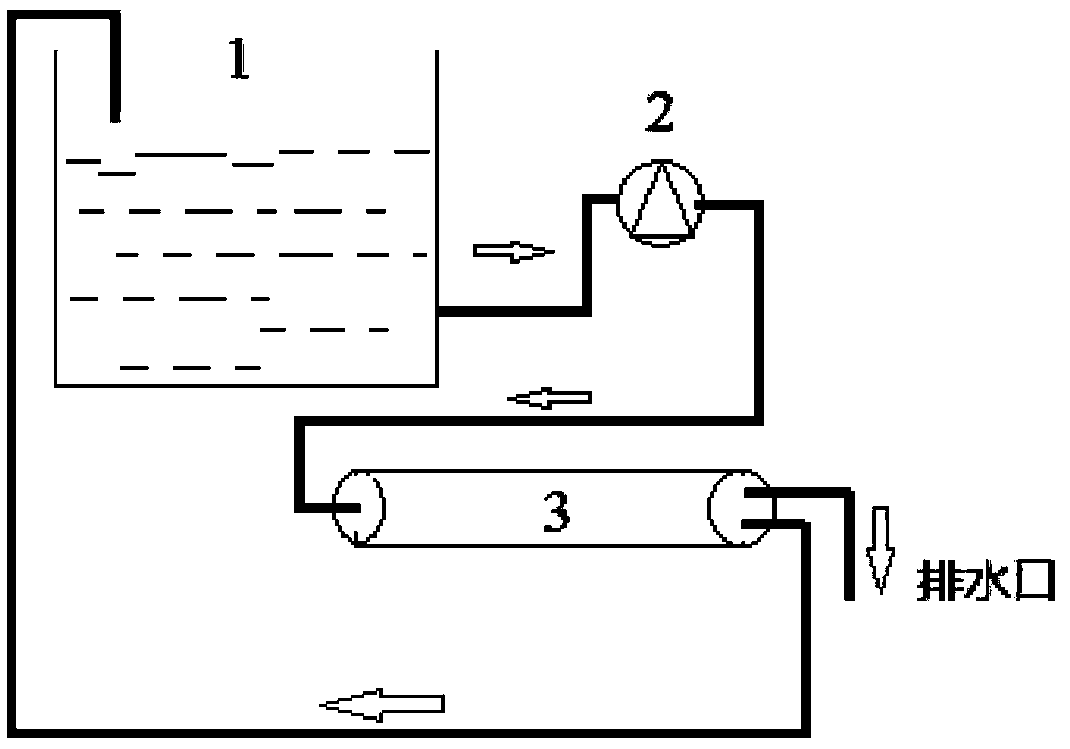

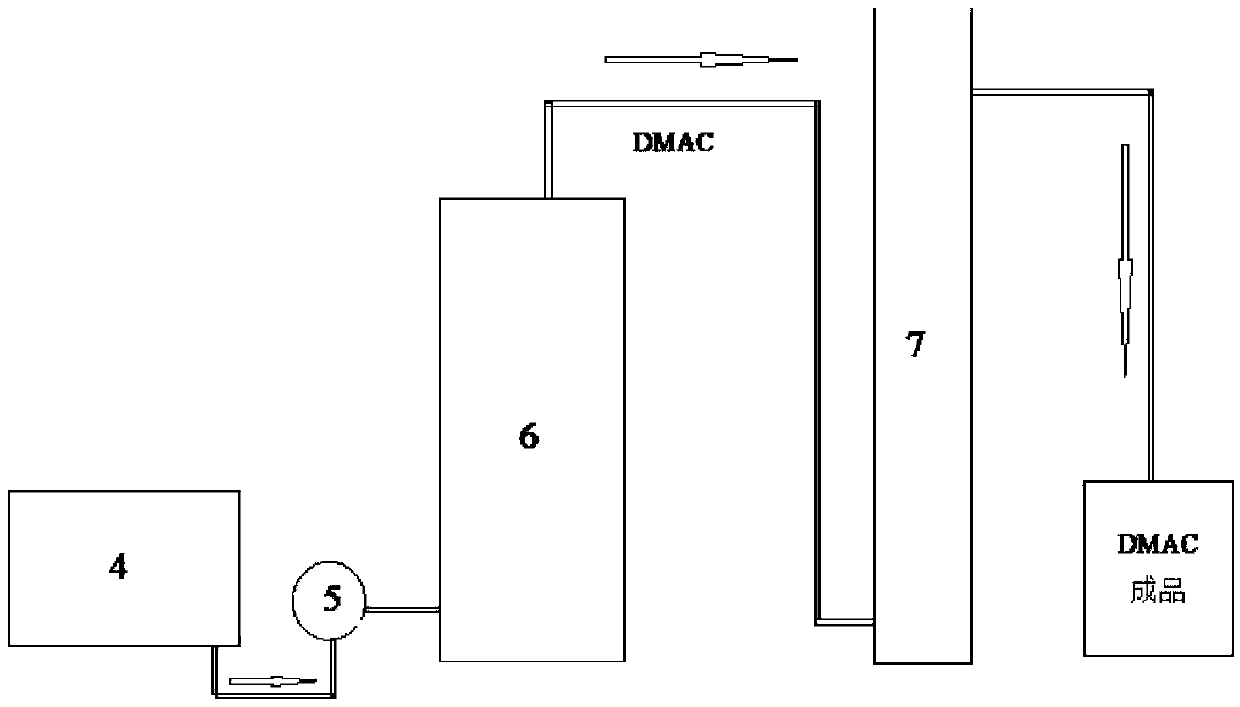

[0034] A low-concentration spinning waste recovery device for hollow fiber membranes, comprising such as figure 1 Concentration unit as shown and as figure 2 The distillation unit shown; where:

[0035] The concentrating unit includes a waste liquid tank 1, a first delivery pump 2 and a microfiltration membrane 3. The spinning waste liquid in the waste liquid tank 1 is pumped into the microfiltration membrane 3 through the first delivery pump for concentration, and the membrane produced water is obtained from the microfiltration membrane. The outlet of the filter membrane 3 is discharged, and the concentrated solution is further passed into the waste liquid tank 1, and concentrated in circulation until the set concentration of the preliminary concentrated solution is reached;

[0036] The distillation unit compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com