Preparation method of fluorescent carbon dots

A carbon quantum dot and fluorescence technology, which is applied in the field of preparation of fluorescent materials, can solve the problems of cumbersome preparation methods of semiconductor quantum dots and organic dyes, prone to photobleaching, unfriendly to the environment, etc., and achieves short preparation cycle, low price, and easy operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

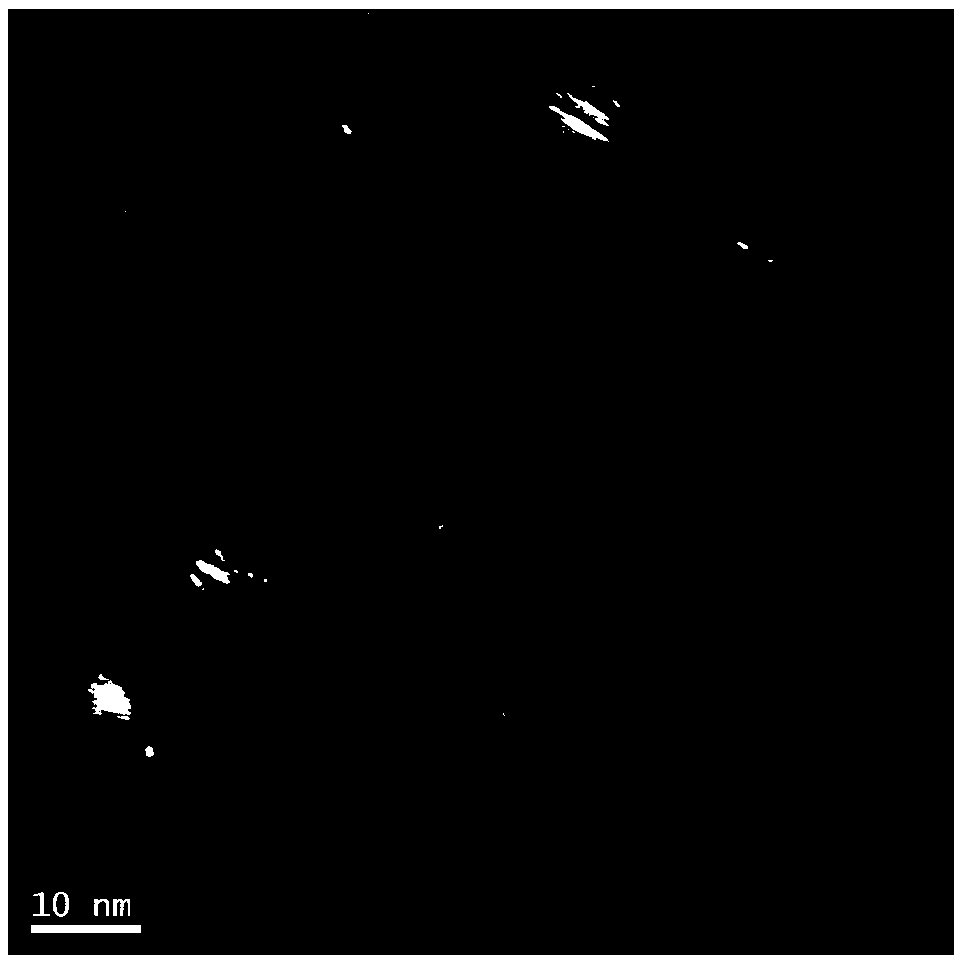

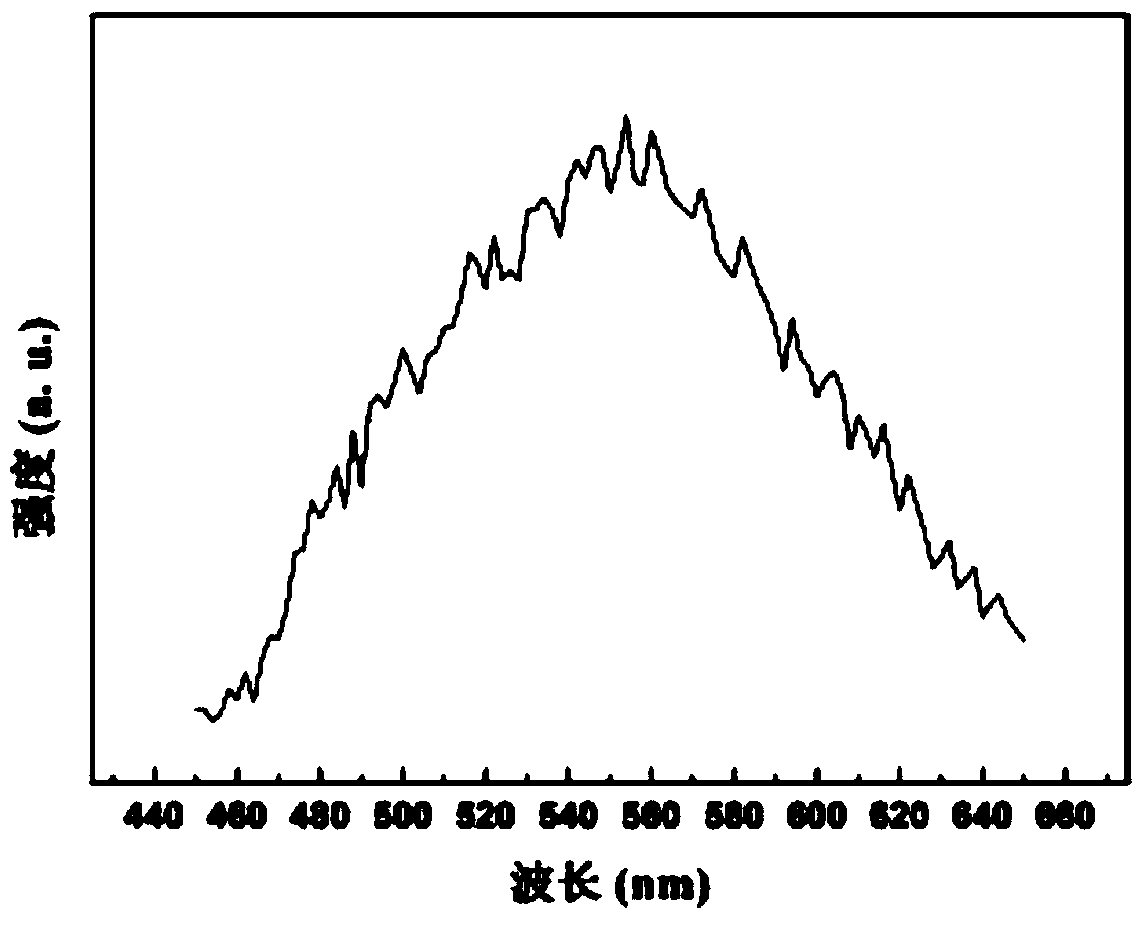

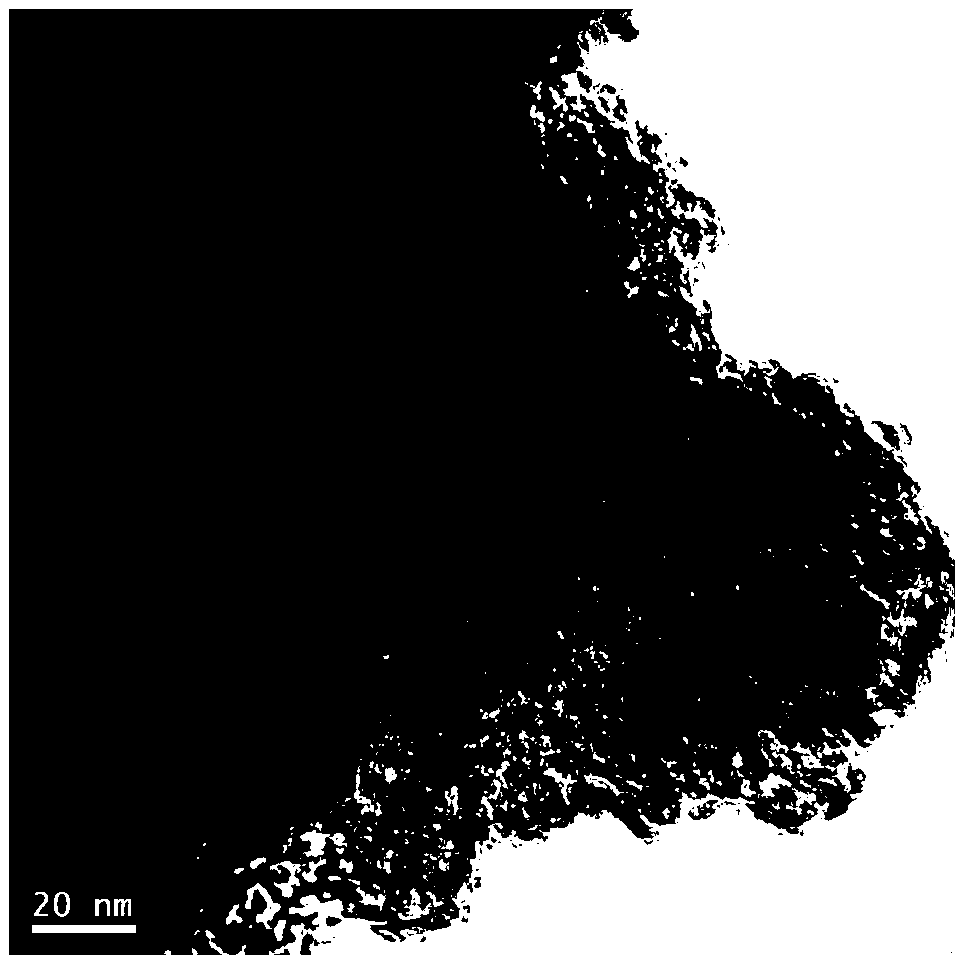

[0015] Specific embodiment one: the preparation method of a kind of fluorescent carbon quantum dot of present embodiment is to carry out according to the following steps:

[0016] 1. Add K to concentrated sulfuric acid with a mass concentration of 95% to 98% under stirring at room temperature 2 FeO 4 and natural flake graphite, the stirring time is 1h to 1.5h to obtain the reaction solution, the reaction solution is centrifuged to obtain liquid and precipitate, the liquid is recovered, the precipitate is centrifugally washed 3 to 5 times, and left to dry to obtain graphite oxide powder; The K 2 FeO 4 The quality of the natural flake graphite and the volume ratio of the vitriol oil that mass concentration is 95%~98% are 1kg:(30~50) L; 1kg: (5~10)L;

[0017] 2. Mix the graphite oxide powder obtained in step 1 and concentrated nitric acid with a concentration of 65% to 68% into a microwave reactor and carry out microwave hydrothermal reaction at a temperature of 80°C to 150°C...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is: K described in step one 2 FeO 4 The volume ratio of the mass of concentrated sulfuric acid with a mass concentration of 95% to 98% is 1kg:40L. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass of the natural flake graphite described in step one and the concentrated sulfuric acid whose mass concentration is 95%~98% have a volume ratio of 6kg:40L. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com