Distributing technology simulating crystal granite by vitrified tiles

A granite and vitrified brick technology, applied in the direction of manufacturing tools, supply devices, etc., can solve problems such as instability and marble cracking, and achieve the effects of uniform particle distribution, strong controllability and wide design range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

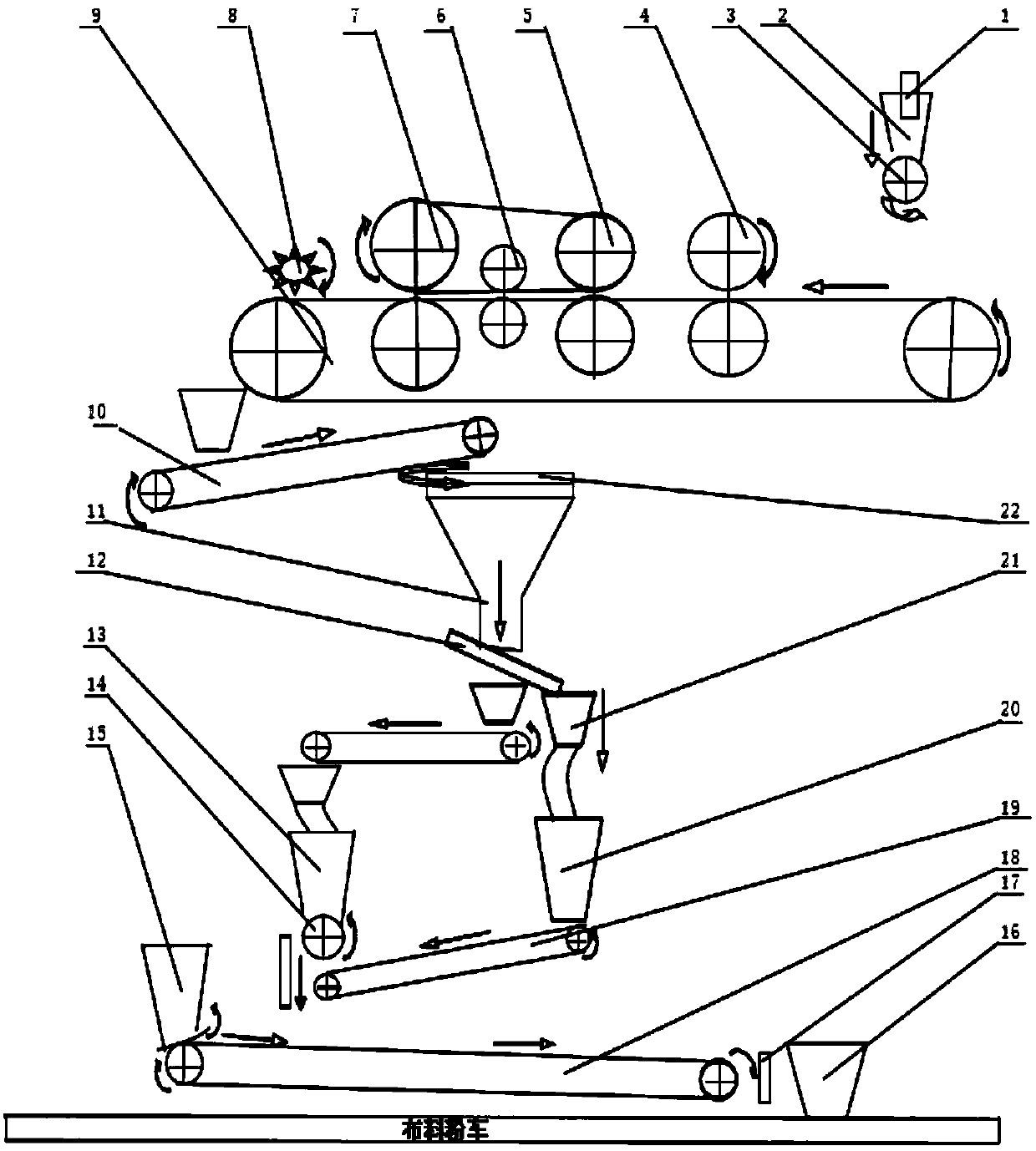

[0028] like figure 1 Shown, a kind of vitrified brick imitation crystal granite cloth process, this process comprises the following steps:

[0029] (1) Tablet granulation: the powder is input into the tablet granulation device and pressed into flakes, and cut into strips by a cutter; the tablet granulation device includes a feeding tube 1, a powder hopper 2, a rotary Cylinder 3, at least one group of pre-compression rollers (in this embodiment, pre-compression rollers include two groups: pre-compression roller a4 and pre-compression roller b5), adjustment roller 6, pressing pair of rollers 7, cutter 8, main belt P9, The feeding pipe 1 is sequentially connected to the powder hopper 2 and the rotating drum 3 to form a feeding assembly. The feeding assembly is arranged above the head of the main belt P9. They are arranged on the main belt P9 in turn, and the cutter 8 is arranged at the tail of the main belt P9.

[0030] (2) Pan granulation and separation: The material after tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com