A copper foil cutting and cleaning device and method

A cleaning device and copper foil technology, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as sticking marks, time-consuming and labor-consuming, incomplete cleaning, etc., to reduce oxidation situation, the effect of reducing the length of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

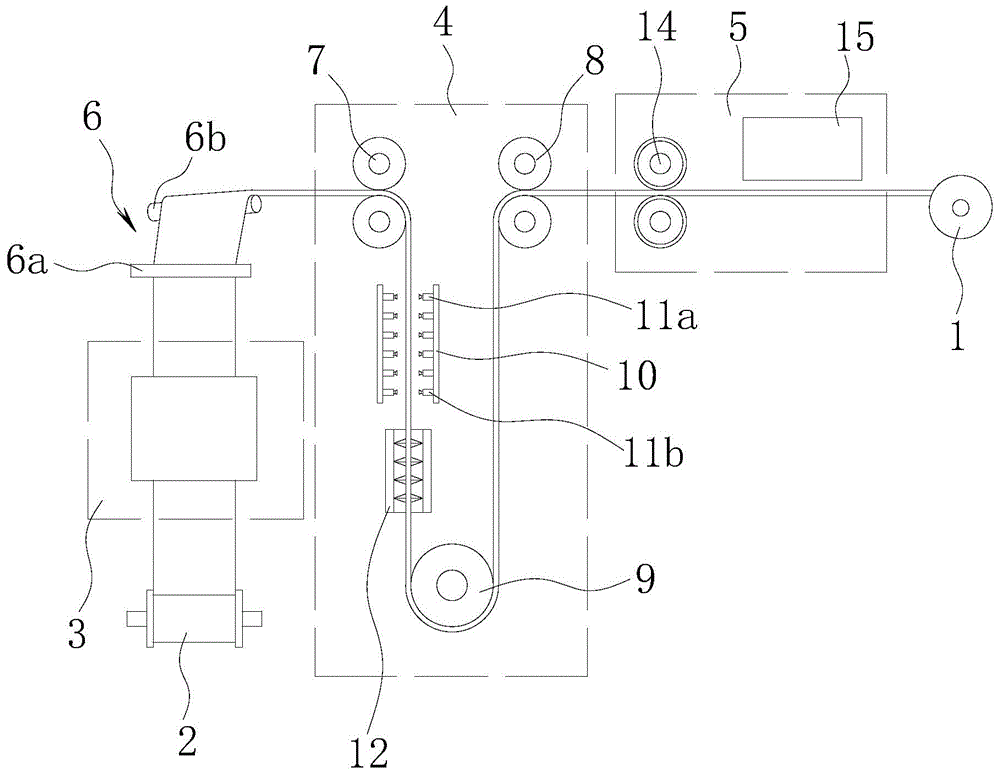

[0032] refer to figure 1 with figure 2 As shown, a copper foil slitting and cleaning device includes a rewinding roller 1 and an unwinding roller 2 that cooperate with each other. Between the rewinding roller 1 and the unwinding roller 2, a slitting area 3, In the cleaning area 4 and the drying area 5, the copper foil located in the slitting area 3 is arranged along the horizontal direction. When the copper foil is slit, the horizontal slitting method is generally adopted, so in the slitting area 3, the end face of the copper foil is along the horizontal direction. Orientation settings.

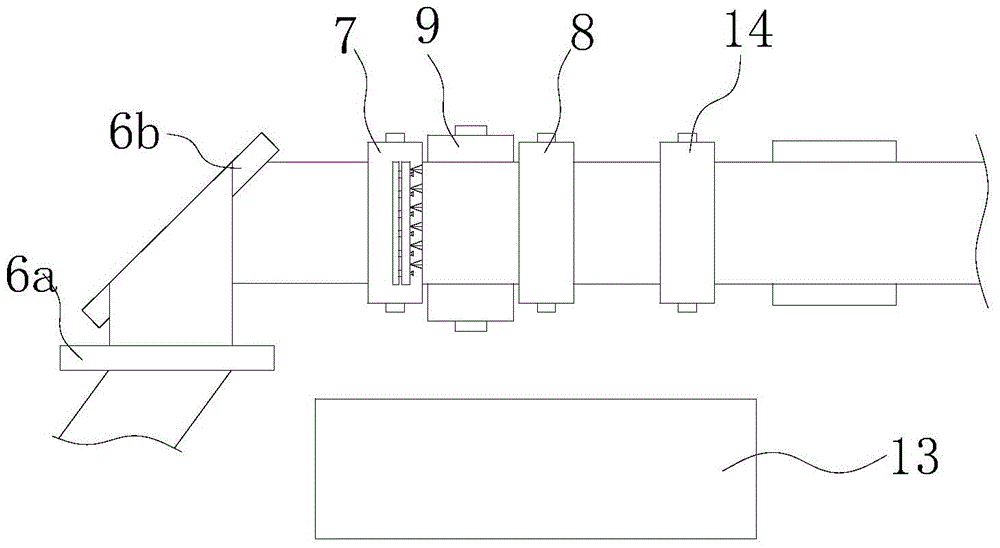

[0033] A copper foil reversing mechanism 6 is provided between the slitting area 3 and the cleaning area 4. The copper foil reversing mechanism 6 consists of a horizontal guide roller 6a arranged in the horizontal direction and a reversing roller arranged obliquely on the side of the horizontal guide roller 6a. Composed of guide roller 6b; the reversing guide roller 6b is located on the si...

Embodiment 2

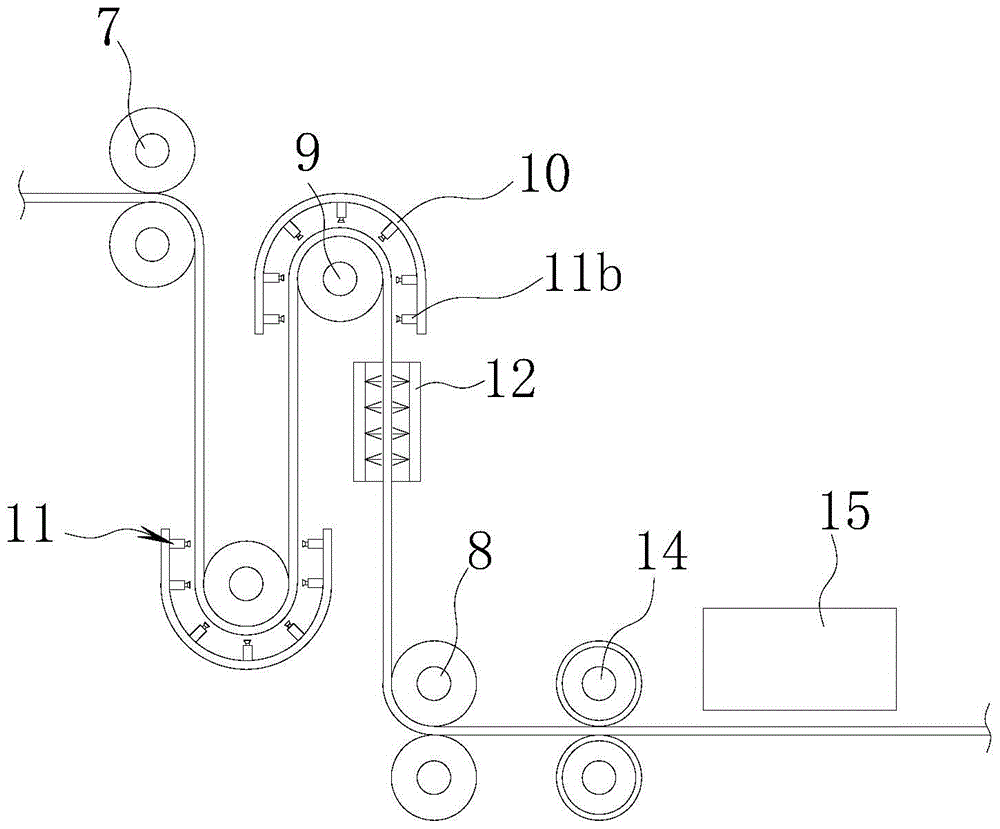

[0047] refer to image 3 As shown, in a copper foil slitting and cleaning device of this embodiment, the structure of the cleaning device is basically the same as that of the cleaning device in Embodiment 1, the only difference is that the number of the 9 guide rollers is two , the feed roller 7, the discharge roller 8 and two guide rollers 9 cooperate to make the copper foil advance along the S-shaped path; the mounting plate 10 is arranged on the outside of the S-shaped path conversion part, and the nozzles 11 are distributed on the mounting plate 10 on the inner end face. By adopting this structure, the length of the equipment can be effectively shortened, and the occupied area of the equipment can be reduced. At the same time, both sides of the copper foil can be cleaned.

[0048] In a copper foil slitting cleaning method of this embodiment, the cleaning method is basically the same as the cleaning method in Embodiment 1, the only difference is that: step (3) is specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com