Xylene disproportionation reaction product separation system based on thermal high-pressure separation process and separation method of the xylene disproportionation reaction product separation system

A disproportionation reaction and reaction product technology, applied in the field of p-xylene disproportionation reaction product separation, can solve the problems of consuming cooling load and increasing the heating load of the fractionation process, so as to reduce heating load, reduce process energy consumption, and avoid repeated cooling- The effect of the heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

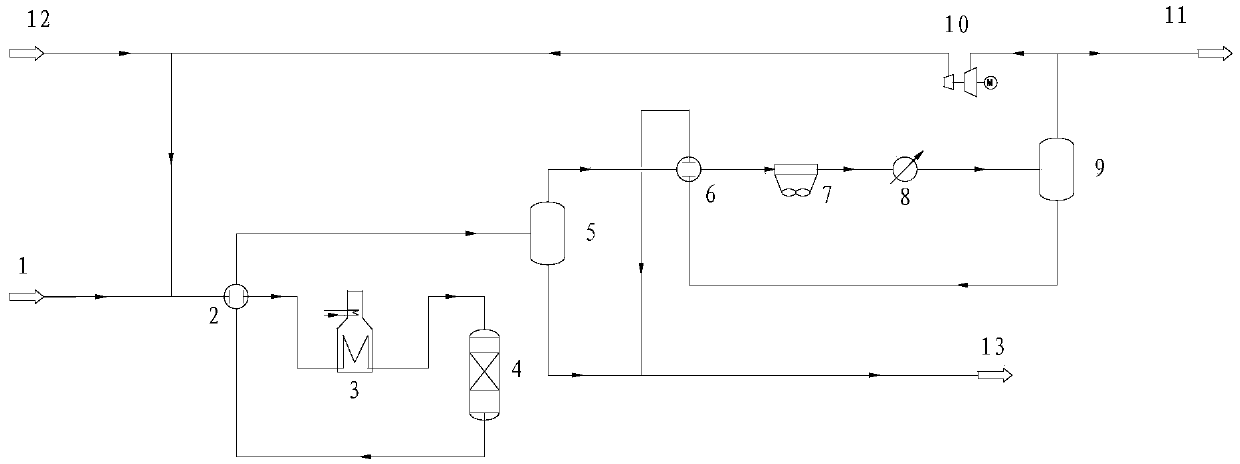

[0038] Such as figure 1Shown, the present invention provides a kind of xylene disproportionation reaction product separation system based on thermal high fractionation process, described system comprises disproportionation reaction system and reaction product separation system connected successively, and described reaction product separation system comprises thermal high fractionation tank 5. Heat exchanger 6, air cooler 7, water cooler 8 and reaction product separation tank 9; the gas discharge port of heat high fraction tank 5 is connected with heat exchanger 6, air cooler 7, water cooler 8 and reaction product separation tank successively The feed port of 9 is connected, and the liquid discharge port of reaction product separation tank 9 is connected with heat exchanger 6.

[0039] The disproportionation reaction system includes a feed heat exchanger 2, a heating furnace 3 and a disproportionation reactor 4 connected in sequence; the discharge port of the disproportionation...

Embodiment 2

[0042] Taking the 1.4 million tons / year disproportionation unit of an oil refinery as an example, the device described in Example 1 was used to separate the xylene disproportionation reaction product.

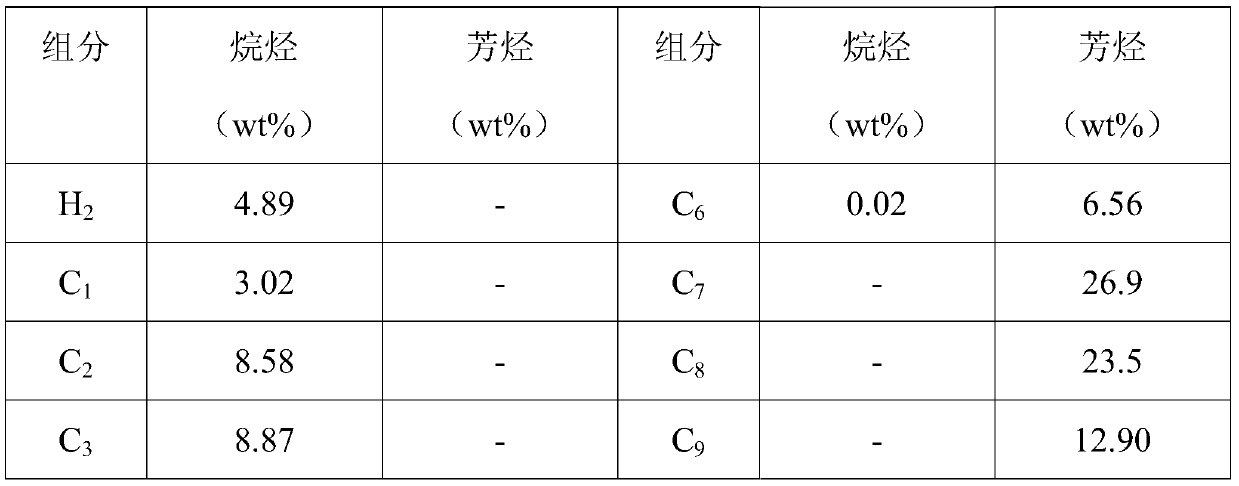

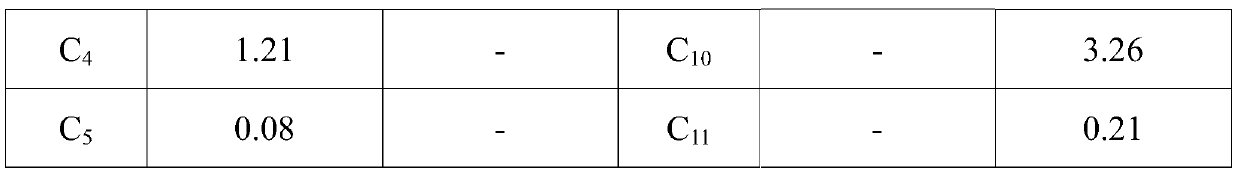

[0043] The disproportionation reaction feed 1 enters the feed heat exchanger 2 as a refrigerant, and enters the heating furnace 3 and the disproportionation reactor 4 after heat exchange, and the disproportionation reaction is carried out in the disproportionation reactor 4, wherein the temperature of the disproportionation reaction is 350-460°C. The reaction pressure is 2.88-3.08MPa, the disproportionation reaction product (its specific composition is shown in Table 1) enters the feed heat exchanger 2 and after heat exchange with the disproportionation reaction feed, the temperature reaches 100-120°C, and enters without cooling after heat exchange. Thermal high-separation tank 5, the first gas-liquid separation is carried out in the thermal high-separation tank 5, wherein the t...

Embodiment 3

[0057] Except that the temperature of the feed heat exchanger 2 and the disproportionation reaction feed heat exchange reaches 90-100°C, the temperature of the thermal high-separation tank is 90-100°C, and the pressure is 2.5MPa, and the reaction product separation tank 9 in the heat exchanger 6 After the liquid phase heat exchange, the air cooler 7 and the water cooler 8 are cooled to a temperature of 30°C, the pressure of the reaction product separation tank 9 is 2.4MPa, the liquid phase obtained by the thermal high fraction tank 5 and the liquid phase of the reaction product separation tank 9 Except that the temperature reached 80°C after mixing, other operating procedures and material consumption were the same as those in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com