Method for manufacturing 3D printing guide plate for single-open-door cervical vertebra surgery

A technology of 3D printing and manufacturing methods, which is applied in the fields of surgery, bone drill guidance, medical science, etc., can solve the problems of increasing the difficulty of surgery, achieve the effects of reducing the difficulty of surgery, improving the quality of surgery, and reducing operational errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

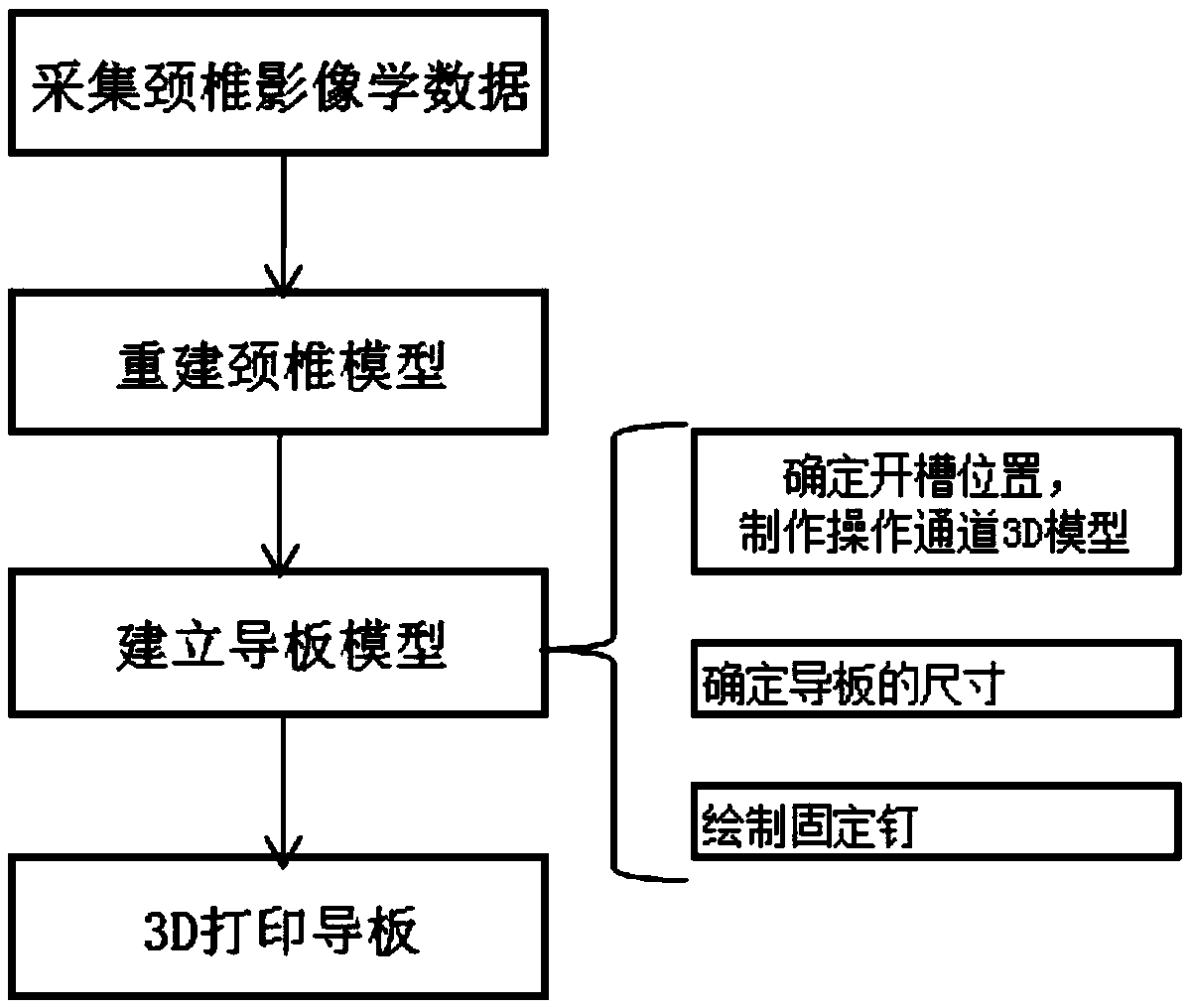

[0034] The software used in this embodiment includes Mimics and 3-matic, and of course other software can also be used in other embodiments. Such as figure 1 As shown, the manufacturing method of the 3D printing guide plate for cervical single-door surgery disclosed by the present invention comprises the following steps:

[0035] a. Data collection: The patient underwent a thin-section CT scan of the neck to obtain the original imaging data of the patient;

[0036] b. Cervical spine model reconstruction:

[0037] b1: Obtain the DICOM file storing the original data of the patient's cervical spine imaging;

[0038] b2: Import the DICOM file into MIMICS software to reconstruct the 3D model of the cervical spine;

[0039] c. Guide plate model establishment:

[0040] c1. save the cervical vertebra 3D model in step b as an STL format file;

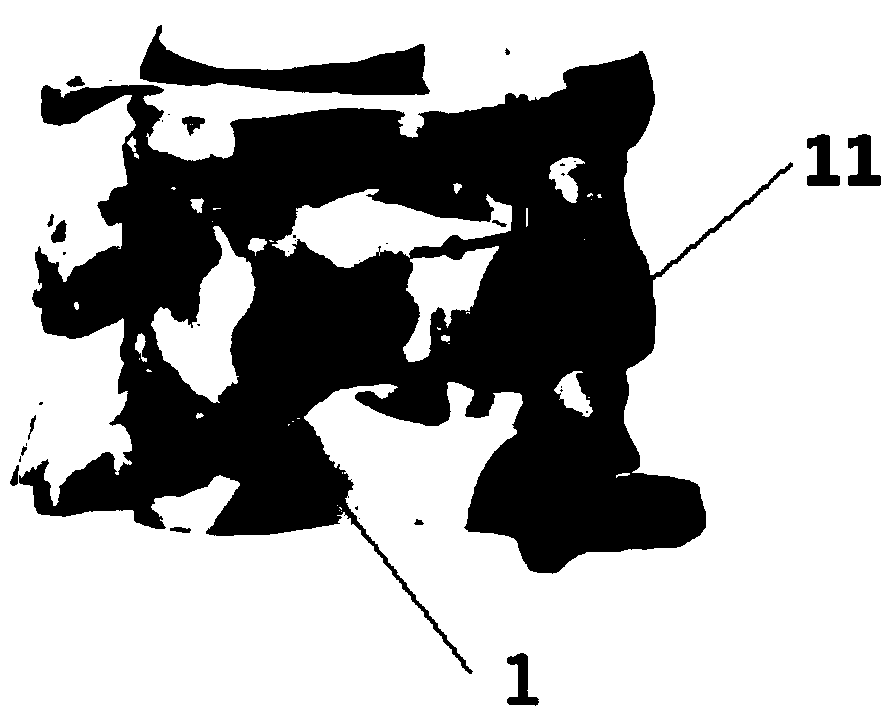

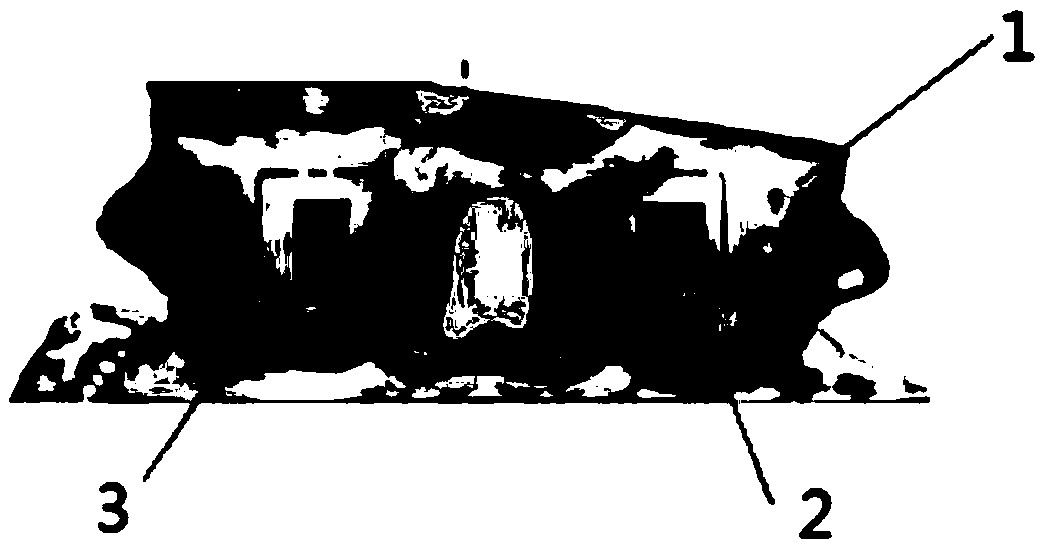

[0041] c2. Open the STL format file in step c1 in 3-Matic software, such as figure 2 As shown, the spinous process 11 of cervical verteb...

Embodiment 2

[0053] Such as Figure 10 As shown, the difference between this embodiment and embodiment 1 is that the following operations are performed before step d: use 3-Matic software to create two fixing nails 7, and assemble the two fixing nails 7 on both sides of the notch 10 respectively, so that the fixing The nail 7 is located between the grinding and drilling operation channel 8 and the gap 10, the direction of the fixing nail 7 is parallel to the gap 10, and perpendicular to the back surface of the lamina; then Boolean operation is performed on the guide plate model obtained in step c6 and the fixing nail 7 to obtain The guide plate model of the drilling operation channel 8 and the fixed nail channel 9; finally, the three-dimensional data of the guide plate model with the grinding and drilling operation channel 8 and the fixed nail channel 9 are imported into the 3D printer to make a solid guide plate.

[0054] When using the guide plate, fully expose the lower edge of the C2 t...

Embodiment 3

[0056] The software used in this embodiment includes Mimics and 3-matic, and of course other software can also be used in other embodiments. Such as figure 1 As shown, the manufacturing method of the 3D printing guide plate for cervical single-door surgery disclosed by the present invention comprises the following steps:

[0057] a. Data collection: The patient underwent a thin-section CT scan of the neck to obtain the original imaging data of the patient;

[0058] b. Cervical spine model reconstruction:

[0059] b1: Obtain the DICOM file storing the original data of the patient's cervical spine imaging;

[0060] b2: Import the DICOM file into MIMICS software to reconstruct the 3D model of the cervical spine;

[0061] c. Guide plate model establishment:

[0062] c1. save the cervical vertebra 3D model in step b as an STL format file;

[0063] c2. Open the STL format file in step c1 in 3-Matic software, such as figure 2 As shown, the spinous process 11 of cervical verteb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com