Machining method of breathable steel ring strap

A processing method and technology of breathable steel, applied in clothing, bras, applications, etc., to achieve the effect of improving air permeability, improving comfort, improving wearing comfort and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

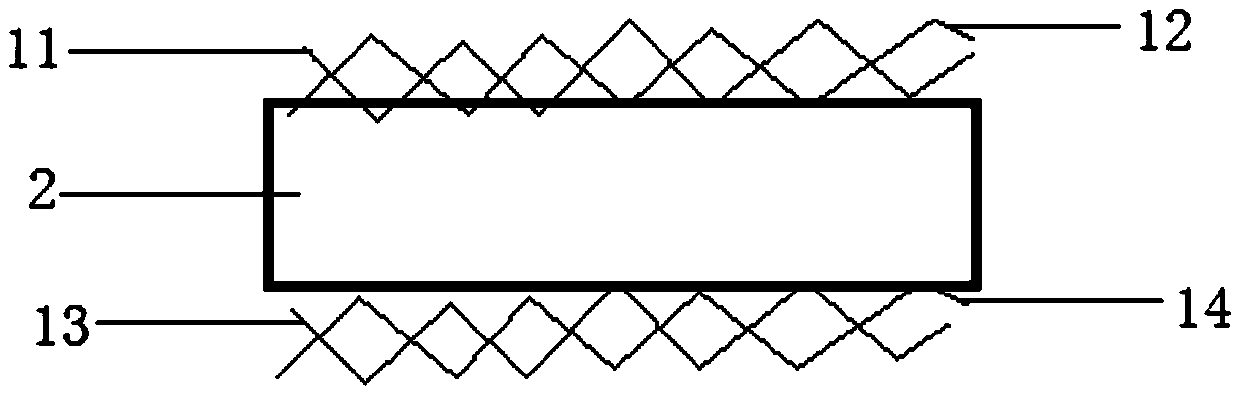

[0057] Please see attached figure 1 , 2, a breathable steel ring belt, which includes the upper webbing 1 and the lower webbing 4, between the upper webbing and the lower webbing using fishing wire 3 to connect.

[0058] The upper webbing is provided with a partial hollow structure, and the partial hollow structure is a steel wire hole 2 .

[0059] The fishing thread is one of nylon monofilament or polyester monofilament;

[0060]The width ratio of the upper webbing and the lower webbing is 2:1; it can be adjusted according to actual needs.

[0061] The width of the fishing line and the lower ribbon is 1:1; it can be adjusted according to actual needs.

[0062] The width of the wire hole can be adjusted according to actual needs.

[0063] A processing method of a breathable steel ring belt, the specific steps are:

[0064] The warp of the upper webbing is nylon fiber and spandex, the weft of the upper webbing is nylon fiber; the warp of the lower webbing is nylon fiber and...

Embodiment 2

[0091] Please see attached figure 1 , 2, a breathable steel ring belt, which includes the upper webbing 1 and the lower webbing 4, between the upper webbing and the lower webbing using fishing wire 3 to connect.

[0092] The upper webbing is provided with a partial hollow structure, and the partial hollow structure is a steel wire hole 2 .

[0093] The fishing thread is one of nylon monofilament or polyester monofilament;

[0094] The width ratio of the upper webbing and the lower webbing is 2:1; it can be adjusted according to actual needs.

[0095] The width of the fishing line and the lower ribbon is 1:1; it can be adjusted according to actual needs.

[0096] The width of the wire hole can be adjusted according to actual needs.

[0097] A processing method of a breathable steel ring belt, the specific steps are:

[0098] The warp of the upper webbing is nylon fiber and spandex, the weft of the upper webbing is nylon fiber; the warp of the lower webbing is nylon fiber an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com