Base-network-based self-striding long cantilever agricultural work platform

A technology of working platform and long cantilever, applied in the field of mountainous and hilly areas, can solve the problems of unfavorable sustainable development, easy to cause accidents, and damage to the field body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

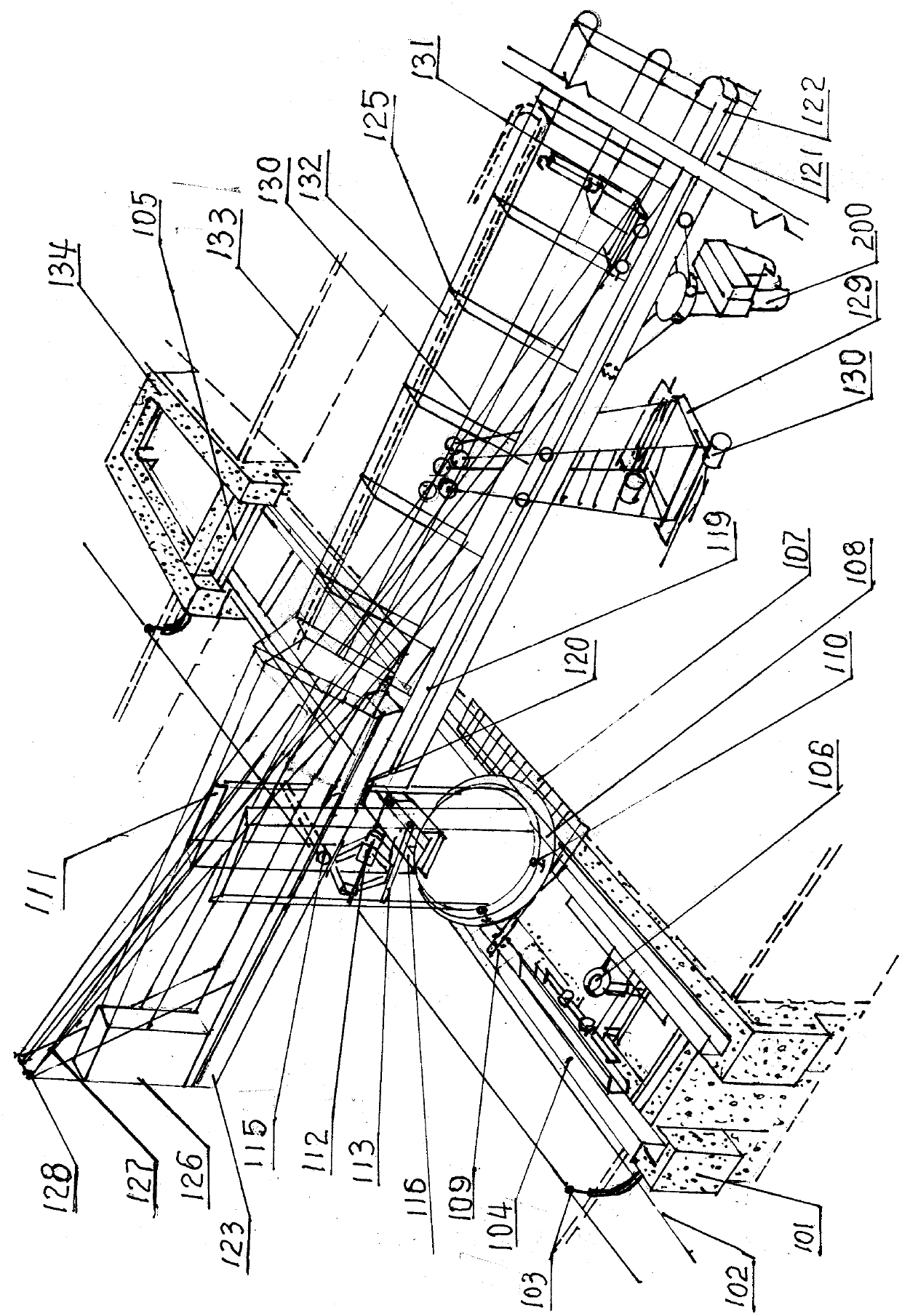

[0011] like figure 1 and figure 2 Shown: reinforced concrete base 101, power cable 102, simple cableway and pile 103, straight rail row 104 for the longitudinal translation of the cantilever platform, rear locking device 105 of the rail row, front locking device 106, supporting structure 107 , the middle platform 108, the wheels 109 running on the rail row, the track wheels 110 seated by Yuanzhou on the middle platform, the base is set to a circular track with a two-column structure 111, and the electric scissor jack 112 arranged at the column structure, so that the jack The shoulder pole 113 of alternate work, the bayonet socket 114 that is provided with on the column structure, the axle 115 that jack is shouldered, the kidnapper body 117 that is one with axle 115 one end, two track wheels 118 are set on its one long side, also set on the column structure The mooring station 116, the cantilever operating platform 119, the usual locking device 120, and the cantilever are wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com